Using blower-driven high-velocity air knives or nozzles alone on simple part geometries can reduce total drying energy by 75% or more compared to using heater tunnels or compressed air.

One of the highest-cost areas for today’s modern coating lines continues to be the drying of parts after the pretreatment, post-wash and prepaint cycles. One way to reduce drying costs is by implementing effective blow-off drying. While this technology is not new, advances in system design are making manual drying more efficient, stationary drying less energy-intensive, and are increasing the coverage area of low-pressure multi-nozzle systems with repeatable results.

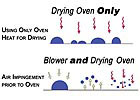

Figure 1. Combining high-velocity blow-off air with a heater tunnel can optimize performance and energy savings.

New Opportunities

Twenty years ago, the Montreal Protocol (the multi-national agreement to phase out chlorofluorocarbons, or CFCs) was the basis for the conversion away from solvent-based parts cleaning systems in favor of today’s aqueous cleaning methods. Over the past two decades, the quality of water-based coatings has improved, while powder coating has become an increasingly popular coating method. Both coating technologies have resulted in the need for ever-more-stringent water-based cleaning and drying systems. Ovens became the “default method” for most drying processes; however, just as technology has been improving the quality and speed in other areas of the coating process, advances in parts drying are now seen as the latest opportunity to further coating quality improvements. Advanced parts drying techniques also can achieve significant cost reductions in both energy and labor associated with coating lines. With the continuing escalation of electric and natural gas costs, together with higher labor rates and the need to compete in a global market, parts drying is no longer being viewed as just a necessary evil of the coating process, but as an opportunity to gain a competitive edge.The conventional method of using heater tunnels alone requires tremendous amounts of energy to boil off “puddles” of water before complete parts drying can be achieved. The major consequences of continuing to use this single drying method are that the final rinse water quality must be very high to prevent surface spotting, the parts are often heated to much higher temperatures than needed for coating application, the heater tunnels are very long, and the total energy costs are very high.

Some companies have turned to air knife or air nozzle drying, but this method also presents challenges. The key to the effective air knife and air nozzle drying of parts is a correct balance of the “2Vs” – velocity and volume. While compressed air provides more than enough velocity (pressure), the amount of horsepower required to generate enough volume (in cubic feet per minute, or cfm) to project the air to the surface of the parts is considerable. In fact, the compressor is wasteful on most blow-off applications, as the air nozzle or air knife pressures are at 50% or less of the 100+ psi that a compressor produces.

A better alternative is a centrifugal blower system with high-velocity air nozzles. Since air volume is cheaper than pressure, a centrifugal blower system has a 4:1 operating cost advantage. A typical 20-hp centrifugal blower at 3 psi can replace what would be 80-hp of compressed air for the same blow-off performance. Using blower-driven high-velocity air knives or nozzles alone to reach 100% dry parts can reduce total drying energy by 75% or more compared to using heater tunnels or compressed air. However, this solution is only feasible for simple part geometries or low-volume production runs. For many applications, combining high-velocity blow-off air with a heater tunnel can provide the best of both technologies while reducing energy consumption by 50-75% (see Figure 1).

Handheld Nozzles for Manual Drying

For some part geometries or exceptionally large-sized parts, there is no substitute for using an operator with a hand-held air nozzle to get into blind spaces and remove the “puddles” before the pre-paint drying oven or to provide complete air drying before painting. Using high-velocity air nozzles with centrifugal blowers can significantly increase efficiency compared to using compressed air nozzles.In April 2007, one of the world’s largest construction machinery companies started up its new prepaint wash/dry station on its 90-ton dump truck bed line at its mine and quarry equipment division in Monterrey, Mexico. The sheer size of these truck beds, along with the low production rate for these specialized units, meant that a manual spray wand wash station and a handheld blow-off nozzle drying method were the most cost effective ways to handle these 20 x 12 x 9-ft (6.6 x 3.7 x 2.8-m) parts.

After final fabrication, welding and deburring, the truck beds are transported on high-load carts into the wash and dry station. On either side of the dump beds, one operator stands on a cherry picker-style moving platform to perform all of the power spray washing and rinsing, followed by the drying process. For the drying cycle, a 40-hp, 3-psig centrifugal blower was installed to supply air through an air distribution system to eight 2-in.-diameter high-velocity air nozzles. Each operator has access to any one of four hand-activated, 2-in.-diameter discharge nozzles that are each at the end of a 20-ft-long flex hose. Each nozzle has a pistol grip handle and a butterfly valve, which the operator can adjust for each use.

Having four nozzle locations for each side of the truck bed allows for maximum mobility of the operators with a minimal weight and low air-pressure losses. At nearly 700 cfm per nozzle and an exit air velocity of 30,000 fpm, the blower-powered nozzle can project the air effectively to surfaces up to 6 ft from the nozzle tip. (In comparison, high-powered compressor-driven nozzles produce only 400 cfm per nozzle.) The blower also has a 50°F increased air temperature for added drying compared to the cold, wet air that a compressed air nozzle would produce.

The end result is fast drying times with a system that only requires 40-hp, compared to the 200 hp that would be required to achieve the same level of drying with compressed air. With the blower-driven system, the plant is able to save 960 kWh of energy in each eight-hour shift. The blower is also quieter, producing only 85-87 dbA versus 95-100 dbA for compressed air.

Fixed Point Blow-Off for Stationary Air Nozzles

The majority of water blow-off systems at the exit of large tunnel washing units are designed to “knock the drops off” so that the prepaint drying oven can finish the job. The reality is that the coating line operators usually are forced to supplement the low-pressure blower/air knives with compressed air nozzles to enhance the water blow-off because the existing system cannot get the parts dry enough. In some cases, the drying oven must be run at full power to finish the drying job.One of the largest U.S. manufacturers of two-stroke engines and portable electric generators had an established tunnel wash line in which various components of the generator frames and mounting hardware were cleaned prior to being powder coated. The company had an existing gas-fired oven that it used for 100% of the drying. Occasionally, an operator stood at the exit of the wash tunnel with a compressed air nozzle to “remove the puddles” before the parts entered the drying oven.

After conducting a labor and gas consumption analysis, the plant concluded that adding an effective blow-off system would provide a good return on investment based on estimates for labor and gas reductions. In July 2006, a high-velocity 10-hp centrifugal blower and two high-efficiency nozzle manifolds were selected for this job. This newest generation of air nozzle blow-off systems uses a high-pressure blower at 2-3 psig to power multiple high-efficiency air nozzles, which results in a 75% or greater efficiency improvement compared to compressed air and reduces heat load in ovens by 25-50% as a result of the increased surface drying. The system also incorporates an aerodynamic air plenum design that provides a small-size manifold, low pressure loss and even air pressure to all nozzles. The swivel nozzles, which can be angled to 45 degrees from the center of any plane, mount directly to the manifolds and require no secondary brackets to support each nozzle in any direction. The number of nozzles per manifold and the discharge nozzle size are selected based on the application, with the minimum nozzle center distance of 6 in. and ranging from 0.5 to 2.0 in. diameter.

The generator frame and parts in this application required four ¾-in.-diameter swivel nozzles on each side of the exit of the wash tunnel. A post-installation cost reduction analysis by the company showed that the natural gas savings alone would yield an $11,300.00 annual savings, resulting in a 10-month return on investment for the total installation cost. This analysis did not include additional savings on labor and compressed air, or the quality improvements experienced by the company.

The most recent innovation in multi-nozzle systems has been to incorporate the pinpoint accuracy of a swivel nozzle while getting 100% vertical coverage of the air to the parts without doubling the blower horsepower.

Reciprocating Nozzle Manifold Systems

Some attempts have been made over the years to cause air nozzles on low-pressure multi-nozzle systems to pivot on their inlet axis to increase the coverage area. The most recent innovation has been to incorporate the pinpoint accuracy of a swivel nozzle while getting 100% vertical coverage of the air to the parts without doubling the blower horsepower. These next-generation swivel nozzles can be individually aimed at the toughest water-holding locations of parts while the entire manifold is actuated up and down on a 6 to 12-in. stroke to hit every inch of the height of the parts as they pass by on the conveyor. The result is 100% drying coverage to the outer vertical or horizontal surfaces of parts, with high-velocity swivel air nozzles using the lowest possible horsepower.A multinational manufacturer of hydraulic pumps and motors, making products ranging from 6 to 14 in. high and 4 to 8 in. in diameter, recently wanted to update the drying system on its spray paint line. The plant’s existing water blow-off system consisted of a 15-hp high-flow fan and multiple flat jet nozzles, but the plant still required an operator to perform spot drying with a handheld nozzle on certain motors.

The motors travel single file on an indexing conveyor through an enclosed blow-off chamber, where the parts stop for 40 seconds and rotate 10 times in a stationary location, so a 15-hp high-pressure blower was chosen to power five ¾-in. and 1-in. air nozzles. These multiple 30,000 fpm air velocity nozzles are actuated up and down on a 12-in. stroke at 2-second cycle times while the motors rotate. This design effectively offers 100% water blow off coverage while eliminating 35-40 hp of compressed air and allowing for the relocation of one full-time operator to more productive duties on the line. The dedicated labor savings and compressed air reduction resulted in a short payback for this system.

A Good Return

Operating costs are part of every company’s overhead, but applying these costs to every part that gets spray painted or powder coated is a real challenge. Does a light-gauge part with 10 ft2of surface area have the same burden applied as a 100-lb steel frame with 2 ft2of coated surface? The heated drying tunnel length and temperature might be set based on the heavy parts, but if the lightweight parts are 80% of production, a lot of energy (overhead) is being wasted to accommodate the exceptions. This situation can negatively affect the ability of a painting line to be competitive to others that might have already optimized drying efficiency.Every plant’s investment in automation and energy reduction needs to demonstrate a good ROI, so be sure to look at the total cost of ownership - including operating costs - for whatever equipment is selected. The right system can enhance coating quality while improving bottom line profitability.

For more information about blow-off dryers and air knife systems, visit www.sonicairsystems.com.

Report Abusive Comment