Stiffness is an interesting issue for elastomers. Commonly, for chain extension, 1,4-butanediol is used. In order to increase stiffness we have synthesized and tested the performance of a new diol. This diol contains an aliphatic ring that will function in obtaining a more rigid chain, but without affecting other properties.

Synthesis of 1,1-Cyclohexanedimethanol

The synthesis of 1,1-cyclohexanedimethanol (CAS: 2658-60-8) has been carried out from cyclohexanal [(2043-61-0) 98% (40.0 g = 0.350 mol) kindly supplied by DKSH GmbH], formaldehyde 44.8 % (51.6 g = 0.770 mol) and 52.0 g methanol. Raw materials were loaded in a 250 ml 3-neck round bottom flask with mechanical stirring. The solution was heated to 40 ºC and a sodium hydroxide solution [49.9 % (30.9 g = 0.385 mol)] loaded drop wise over a period of 20 minutes. The temperature was limited at 40 ºC and maintained for 10 minutes after sodium hydroxide addition and then increased to 45 ºC and maintained at this level for 40 additional minutes. The obtained solution was cooled to room temperature when the crystalline diol started to precipitate. Water (50 mL) was loaded and the pH adjusted from 12 to 7 with formic acid 10% solution (33.2 g = 0.072 mol). The crystal slurry was distilled to remove the methanol and then filtered. The crystals were washed with water and dried at 40 ºC. The product may be re-crystallized from a 9/1 blend of water/ethanol. However, by distillation, pure 1,3-cyclohexanedimethanol (purity 99.9%) was obtained with an 81% yield.

Positioning the 1,1-Cyclohexanedimethanol

The physical properties of 1,1-cyclohexanedimethanol are presented along with other diols in Table 1.Structure-wise, 1,1-cyclohexanedimethanol is a 1,3-propanediol homologue, but it is also a homologue of cyclohexanedimethanols. It imparts properties from both diol groups, exhibiting special characteristics due to possible co-facial orientation of the rings with respect to each other as such, or on the polyester/ polyurethane chain (Figure 1). Thus, 2,2-dimethyl-1,3-propanediolpolycarbonate is a crystalline polyester having a Tg of 109 ºC, while the corresponding polyester of 1,1-cyclohexanedimethanol has a Tg of -15 ºC.

Experimental/Discussion

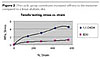

1,1-cyclohexanedimethanol was tested as a curative for pre-polymers to yield an elastomer that was then subjected to tensile testing to confirm the increased stiffness expectations.The elastomer was produced from TDI-terminated polytetramethylene glycol [Adiprene L100 (Chemtura)], having an NCO content of 4.05%. The prepolymer was cured with curing agents, as shown in Table 2.

To prepare the sample, the prepolymer and respective curative diol were heated to 90 °C under vacuum to dry the components. A stoichiometric amount of diol was blended into the prepolymer after a few minutes of stirring before a vacuum was once again applied to remove air bubbles. The material was then poured into the pre-heated mould at 90°C, put into the oven and cured for 16 h at 120°C. After the curing cycle, a specimen was punched with a dog-bone shaped fixture and tested. All specimens were conditioned for seven days at 23ºC and 50% relative humidity prior to physical testing. The tests were carried out according to ASTM D 412-98a using a MTS 2-M screw-driven machine equipped with the testexpert version 2.0 software for data treatment (Figure 2).

Report Abusive Comment