Alkyd resins have been widely used in the coatings industry because of their excellent gloss, corrosion resistance and adhesion to various substrates. Changes in consumer preferences and VOC regulations have mandated that the industry reduce the VOC of coatings. In some cases, this necessitates a switch from solvent-based to water-based technology.

Comprised of aromatic moieties and lipophilic fatty acids, alkyd polymers are water-insoluble hydrophobic polymers. To create waterborne alkyd systems several techniques have been developed for incorporating the alkyd resin into aqueous systems. The most recent practices focus on stabilizing the alkyd in water utilizing either a dispersion or an emulsification process.

This article discusses the current technology available in the industry and introduces a new polymer that does not contain solvent, or surfactant-related moieties. The new polymer offers markedly improved corrosion resistance while offering typical alkyd benefits. The resin can be supplied as a dispersion with near-zero VOC.

Current Technology

Many desirable alkyd properties result from the excellent film formation and oxidative curing process that alkyds offer. If an alkyd paint is compared to an acrylic latex paint, the molecular weight of the alkyd polymer at the time of coating application is much lower than the latex. It is this low molecular weight that gives the alkyd molecules the mobility they need to flow out to achieve high gloss and excellent adhesion. After application to the substrate, the molecular weight of the alkyd polymer increases through crosslinking by an oxidation reaction of the fatty acid. The corrosion resistance that alkyds are known for is a result of excellent wetting of the substrate and the subsequent crosslinking reaction.

A disadvantage of alkyd polymers is their VOC content. A traditional solventborne alkyd polymer is supplied as a solution polymer. The viscosity of the solution is, therefore, a function of the molecular weight. To reduce viscosity, the molecular weight can be reduced and high solids systems can be pursued. The high solids approach can be successful in some applications, but does not satisfy the need of all applications due to unfavorable coating properties caused by low polymer molecular weight. Another approach is to replace the solvent with a non-VOC using exempt solvents or water. Since exempt solvents can be costly, flammable and often odorous, there is strong interest in using water as the solvent for many coatings. Since alkyds are hydrophobic, the alkyd polymer must be modified to exist in the polar, aqueous environment.

The modification of alkyds for use with water is not a new concept; the first water-compatible alkyds utilized in coatings were water-reducible alkyds. Water-reducible alkyds are supplied at 70-75% solids in hydrophilic glycol ether solvents. Formulators neutralize the carboxylic groups in the alkyd with a base and disperse the alkyd polymer in water. Water-reducible alkyds display excellent corrosion resistance; however, they suffer two major drawbacks: a high VOC of 250-300 g/L and a short shelf life due to poor hydrolytic stability.

One approach used to improve alkyd hydrolytic stability in water is emulsification. Using surfactants, an alkyd emulsion is produced via an emulsification process to yield a surfactant-stabilized dispersion of the water-insoluble alkyd polymer. To accomplish this, a significant level of surfactant, typically 5-10 weight percent of alkyd polymer, is needed. This approach does not require organic co-solvents and has been shown to protect the alkyd from hydrolysis. The drawback to this approach is the high level of migratory surfactant that is utilized. The surfactant can lead to water resistance issues such as blistering and reduced corrosion resistance.

Another approach to improve the hydrolytic stability of a water-reducible alkyd and lower the VOC creates an acrylic-modified alkyd dispersion wherein a hydrolysis-resistant acrylic polymer is placed in the “shell” neighboring the aqueous phase while protecting the “core” alkyd from hydrolysis. To disperse the alkyd polymer in water, salts are created with the acid from the alkyd and a base. Despite the success in extending shelf life and lowering the VOC to about 100 g/L, some acrylic-modified alkyd dispersions demonstrate poor corrosion resistance. This may be due to inefficient grafting of the acrylic onto alkyd, resulting in the formation of high-Tg and high-acid-value acrylic homopolymers. These polymers can result in poor substrate wetting and higher-than-expected water sensitivity.

In most alkyd dispersion manufacturing processes, organic alcoholic co-solvents are needed to achieve a workable viscosity. Removing the organic solvents from the process to achieve zero VOC leads to a high viscosity unless other modifications are made. One such modification is the use of a hydrophilic polyalkylene oxide moiety covalently bound to the alkyd polymer. The bonding of this component to the polymer adds an internal non-migratory surfactant that was shown to lower the dispersion viscosity, allowing for reduced VOCs (US Patent 5,698,625). The inclusion of this hydrophilic component reduces hydrophobicity relative to a traditional alkyd.

Almost all contemporary commercial waterborne zero-VOC alkyd products available contain either chemically bound or physically blended surfactants to either lower the dispersion viscosity or to form an alkyd emulsion. The presence of these water-sensitive components in the coatings inevitably leads to a compromise in coating properties such as corrosion resistance and QUV resistance. Therefore, to widen the use of zero-VOC alkyd products for outdoor application, new technology must emerge in order to produce a zero-VOC alkyd dispersion that does not contain water-sensitive surfactants.

Novel Technology

To overcome the shortcomings of surfactant-containing zero-VOC waterborne alkyd products, we developed a novel process to create a zero-VOC alkyd dispersion without using water-sensitive surfactants. It is well known that alkyd dispersions offer favorable corrosion and QUV resistance because of the absence of surfactants, while alkyd emulsions offer lower viscosity because of spherical morphology in water. Therefore, the ideal product would have the major positive attributes of both technologies: good coating performance and low viscosity. This novel proprietary process creates an alkyd dispersion with emulsion-like morphology without the use of surfactants. By creating a surfactant-free dispersion, the resin can offer strong outdoor coating performance at low dispersion viscosity. When compared to existing alkyd emulsions and existing VOC-containing alkyd dispersions, this novel technology demonstrates much improved corrosion resistance, comparable gloss and dry times, and can be supplied at resin solids of 45% or greater with no added surfactant or solvent.

Results and Discussion

The target application areas for a zero-VOC, surfactant-free waterborne alkyd range from industrial to architectural and include metal and wood substrates. In this work the product is targeting the replacement of solvent-based alkyds. The results discussed focus primarily on metal substrates.

In our tests, five types of alkyd technologies were compared. For the water-based alkyd technologies the formulation contained approximately 10 g/L of VOC from additives. In future work the authors intend to lower this value further. No additional solvent is added to the water-based samples.

Technologies included in this testing and their formulated VOCs include:

- SBA - a Solvent-Based chain-stopped short oil Alkyd resin (<450 g/L);

- ADS - an Alkyd Dispersion Short oil (<75 g/L);

- ADM - an Alkyd Dispersion Medium oil (<25 g/L);

- AES - an Alkyd Emulsion Short oil (<10 g/L);

- EXR - Experimental Resin (<10 g/L).

Resin samples ADS and ADM contain some solvent from the resin manufacturing process and, therefore, have VOCs higher than AES and EXR.

Sample EXR represents a surfactant-free, zero-VOC alkyd dispersion produced by the proprietary process. In the QUV results section, two zero-VOC alkyd dispersions that were tested differed in raw material economics and offer a choice of cost vs. performance. These samples are labeled EXR and EXR2.

The solvent-based alkyd is a high-solids chain-stopped alkyd for industrial use and is formulated to <432 g/L. The solvent-based paint formula appears in Table 1.

All of the water-based alkyd resins were tested using the formula in Table 2. Water was adjusted to equalize the resin solids across all paints. It is worth noting that the water-based alkyd formulation is cobalt-free.

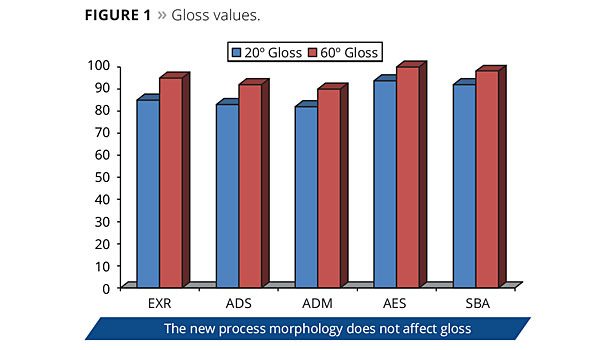

Gloss

Alkyd resins are well known for producing very high gloss. Figure 1 shows that the traditional solvent-based alkyd produced a 20º gloss over 90 units. Most of the other resins were near or over 80 units, with the exception being the short oil alkyd dispersion (ADS). The gloss capability of the experimental technology meets expectations for an alkyd at 85 units. The alkyd emulsion performed very well for 20º gloss, as it surpassed the solvent-based alkyd.

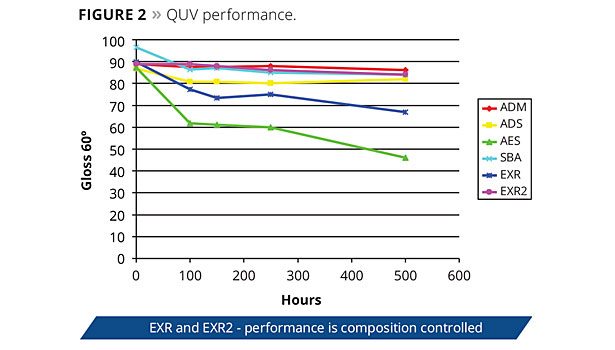

QUV Performance

Paints were tested for QUV-A performance using alternating cycles of light and moisture every four hours. Test results are shown in Figure 2. In this case two experimental zero-VOC alkyd dispersions were tested. As can be seen in the figure, EXR showed greater gloss loss than the solvent-based alkyd. To demonstrate that QUV performance is not a limitation of the composition, but rather a function of polymer composition, EXR2 was run and shows very good gloss retention through 500 h. There is a cost difference between EXR and EXR2, therefore the final QUV performance is a cost vs. performance decision and not a limitation of the technology.

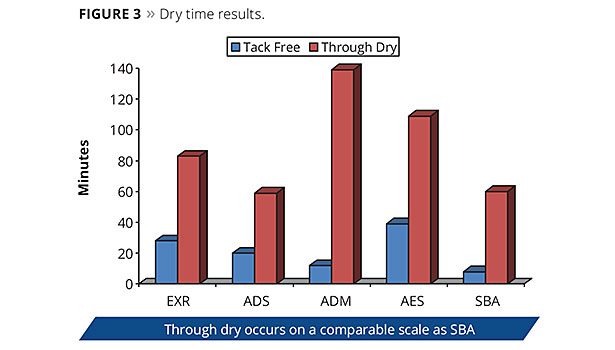

Dry Time

For industrial applications dry time is a critical feature. It is often very difficult to match the dry time of certain solvent-based coatings using water-based technologies. This is especially true when drying under adverse conditions. The dry time results for ambient conditions are presented in Figure 3. The alkyd emulsion showed the longest tack-free time and the second longest through-cure time. The solvent-based chain-stopped alkyd showed the fastest tack-free and through-dry. The experimental resin fell in the middle of the group, offering a tack-free time that was better than the alkyd emulsion, but a little slower than the short oil alkyd dispersion. Despite not drying as fast as the solvent-based alkyd, the experimental technology offered a reasonable through-cure of 80 min. The alkyd dispersion short oil (ADS) shows the potential for water-based systems to match the dry time of the solvent-based chain-stopped alkyd under ambient conditions.

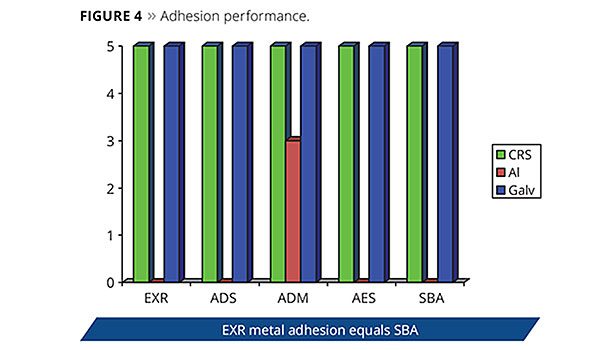

Adhesion

Figure 4 shows the adhesion performance of the paint samples tested on cold rolled steel (CRS), untreated aluminum (Al) and galvanized metal (Galv) panels when tested using ASTM D 3359.

The adhesion of each sample to the various metals was comparable for all samples on cold rolled steel and galvanized metal. On aluminum only the medium oil alkyd dispersion (ADM) showed any adhesion to the untreated aluminum.

Corrosion Resistance

The new alkyd dispersion technology demonstrates one of its greatest performance attributes in corrosion resistance. As can be seen in Figure 5, the alkyd emulsion (AES) and both of the older technology alkyd dispersions (ADS and ADM) show significant failure in this photo. This photo was taken after 142 h of ASTM B117 salt spray testing. The dry film thickness was controlled to 2 mils +/- 0.1. The experimental alkyd dispersion (EXR) performed comparable to the solvent-based alkyd (SBA) when comparing the unscribed field performance. Around the scribe the solvent-based alkyd slightly outperformed EXR. The significant blistering seen in the alkyd emulsion sample after 24 h is also worth noting.

Conclusion

A novel alkyd dispersion has been developed that offers performance similar to traditional solvent-based alkyds at VOC levels near zero. Gloss, dry time and adhesion are comparable to solventborne alkyd samples. QUV results for the new process can be controlled depending on the cost vs. performance that is required. Corrosion resistance performance surpasses existing water-based alkyd technology and is comparable to existing solvent-based technology.

Report Abusive Comment