Within the specialty coatings industry, all coatings are a sum of their parts. Some particles impart sheen, others adhesive strength and others pigmented color. The unique factor is the chemistry behind the coatings that enables the particles to bond to various substrates.

As a result, the polymer industry has developed a variety of materials to meet the demands of the specialty coatings sector. Created decades ago, products such as polyvinyl alcohol (PVOH) are used in water-based coatings and adhesives, while polyvinyl butyral (PVB) helps improve tact, softness and adhesive strength in solvent-based coatings and adhesives.

PVOH and PVB begin as the same molecules. But, through processing technology, they become vastly different in their chemical structure, as well as in the characteristics and properties they offer to the specialty coatings industry. As siblings, they are rivals in some markets and are complementary in others. But, in the end, they are fast-becoming unique solutions to meet the needs of a variety of industries, including maritime, wood adhesives, inks, glues, reflective coatings and more.

PVOH

PVOH was discovered in Germany in 1924, commercialized in 1939 and introduced to the coatings industry in the 1950s. It is typically characterized by its degree of polymerization (DP), which indicates the length of the molecule, and its degree of hydrolysis (DH), which is typically 88 percent or greater and is indicative of the fraction of OH groups. A soluble polymer powder, it can be dissolved into water and creates a viscous, transparent solution that gives it excellent coating properties. These include superior wet-tack and heat resistance, along with improved adhesion to hydrophilic substrates. PVOH can also be crosslinked. It is often used for specialty paper coatings, paints, wood glues and water-based inks. Along with its coating properties, PVOH is an excellent stabilizer in the emulsification process, has foam stability and has good adhesion to cellulosic and inorganic materials.

Hydrophobically Modified PVOH

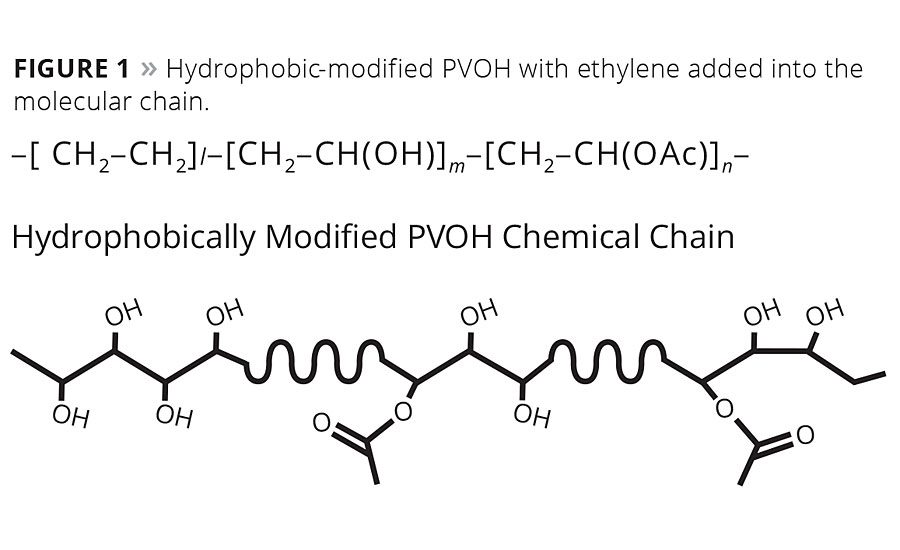

Drawing from experience in other co-polymer fields, Kuraray developed EXCEVAL™, a hydrophobic-modified version of PVOH that adds ethylene into the molecular chain (Figure 1). EXCEVAL is used throughout the emulsification process, specifically in the polymerization and post-addition stages. The product has improved water resistance (compared to traditional PVOH), high surface activity and a low melting point. In addition, it is environmentally friendly, specifically for those seeking a formaldehyde-free solution for creating emulsions.

Within the paper coating industry, EXCEVAL has the ability to make paper competitive to many multilayer plastic-packaging solutions. When paper is coated with EXCEVAL, the material becomes stronger. It also results in high barrier to oils, greases, oxygen, carbon dioxide and nitrogen, while also having better water resistance with better flexibility. The product is also approved by the Food and Drug Administration. This is especially appealing for the packaging of dry food products, including: coffee and tea; powdered soups, milks and drinks; cereals; herbs and spices; dried fruits, nuts and vegetables; hard cheeses; and institution bulk packaging. Such dry foods have the greater gas barrier of PVOH under dry conditions and a reduced weight, thus possessing lower mechanical integrity requirements for lightweight paper packaging.

The wood coatings business, especially the laminated furniture sector, can also benefit from the use of EXCEVAL. A D3 adhesive is used in classifying the amount of humidity that a piece of laminated furniture can withstand, either through frequent short-term exposure to running or condensed water and/or heavy exposure to high humidity. Previous adhesives that incorporated traditional PVOH could not withstand this sort of abuse, limiting PVOH’s applications to D1 and D2 adhesives without crosslinking.

Combining Polymers: Creating PVB

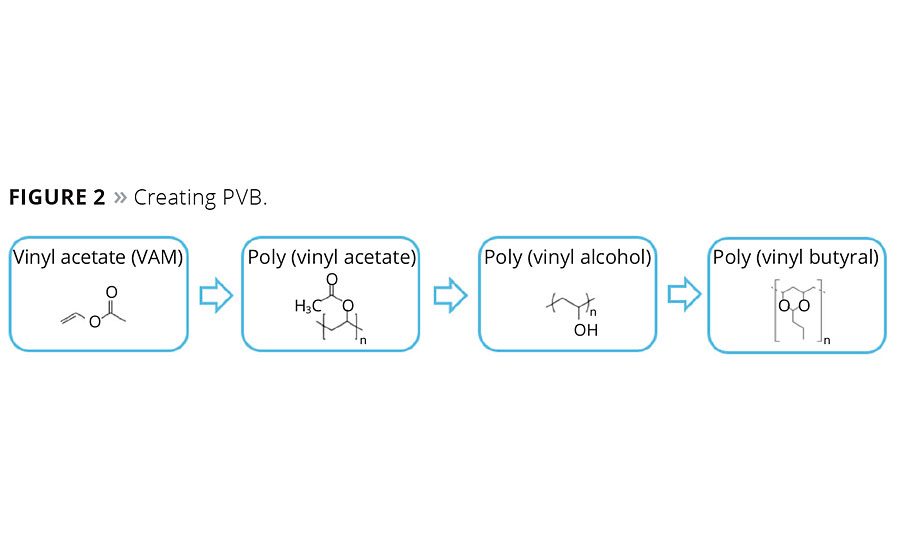

PVB is a polar terpolymer and a real thermoplast that has its roots in PVOH (Figure 2). Creating PVB starts at the beginning of the vinyl acetate (VAM) chain. From there, polyvinyl acetate is created then sapponified into PVOH. Next, it is reacted with an aldehyde to create PVB.

PVB grades are typically characterized by their DP, content of vinyl acetate, degree of acetalization and vinyl alcohol content. Although insoluble in water, PVB can be dissolved in alcohols, esters, glycol ethers and sometimes hydrocarbons and ketones (depending on the grade).

An easily processed polymer, PVB is colorless and offers excellent gloss and strong adhesion to traditionally difficult substrates. Within the coatings market, PVB is an excellent addition to modern primers, lacquers and powder coatings. Some of PVB’s more unique properties include its ability to withstand typically abrasive environments, such as saltwater, making it excellent for maritime applications. It also possesses the ability to bind and adhere metal and magnetic powders, which are most often used for retroflective and magnetic tapes. PVB’s most common application is as the primary adhesive in the glass industry.

PVB Film: A VOC-Free Solution

Over the years, the coatings market has raised demand for products with lower use of volatile organic compounds (VOCs) – solvents that are released into the air as paint dries and can cause acute symptoms, such as headaches and dizziness. Using its experience in the PVB film market, Kuraray developed a unique film for solvent-free coating needs – Mowital™ LP BF.

Mowital LP BF is a thin, plasticizer-free PVB film that uses a roll-to-roll application process free from solvents and dust. The film can adhere to glass, metals, woods and fabrics. It can also be crosslinked with other resins such as epoxies, phenolics and isocyanates without any plasticizer migration. Simply using heat and pressure, a company can get all the benefits of traditional processing with organic solvents, while improving its VOC footprint by using this innovative PVB film.

The Market Today

Within the United States, the coatings market continues to grow and perform at higher rates than GDP growth, ranging from 5-10 percent. This growth is driven by new construction, growth of purchasing power and wealth in developing countries, oil and gas product development, paper board and furniture fabrication, large equipment and automobile purchases.

Within the PVB market, there has been significant recent activity within a variety of specialty coatings. These range from temporary binders for manufacturing ceramic microchips, to retroreflective coatings, to specialty abrasion-resistant primers, to powder paints and primers.

Through collaborative research methods, new solutions are becoming available to meet rising industry needs from decreasing your VOC footprint to using polymer technology to bridge the gap in packaging and coating needs.

For more information, visit www.kuraray.us.com.

Report Abusive Comment