Transportation coatings may bring to mind the protective paint and finishing on automobiles, boats, trains, airplanes or other moving vehicles. While this is an important part of transportation maintenance, an even more vulnerable aspect of transportation is the shipment of bare-metal goods. These goods -whether sheet metal, gears, coil or automobile parts -are at high risk for corrosion even within hours of manufacturing. If not protected, the producers of these products will face high rust claims and customer complaints on their shipments. Often, the protection that is available can be clumsy or inefficient. Vapor Corrosion Inhibitor (VCI) transportation coatings provide a step up from ordinary protective coatings and are a good alternative in cases where VCI packaging options are not preferred.

Transportation Corrosion

Though different metal alloys have different levels of resistance to corrosion, most metals are prone to rapid corrosion with only minimal exposure to moisture and oxygen. This problem is compounded during long-distance and overseas shipping, when goods may pass through extreme environments exposed to humidity and salt spray for weeks or months and not just hours.

In the United States alone, corrosion-prone equipment and motor vehicles are among the most valuable commodities in transit. In 2012, machinery topped the list at $1,836 billion dollars, while motorized vehicles came in third at $1,348 billion (2007 dollars), according to the U.S. Department of Transportation.1 When adding to this the amount of shipping that takes place outside U.S. borders for long periods of time, it is not difficult to imagine the high potential for severe monetary losses from rust claims during domestic and international transportation.

VCI Coatings

While many excellent dry packaging methods exist, temporary coatings are sometimes preferred due to the size or profile of the metal pieces being shipped. For example, it may be easier to spray a coating on a large tractor than to wrap the bulky equipment with film. In other cases, metal parts may have sharp edges that could threaten to puncture a protective film. VCI coatings offer an effective alternative in these situations, with the added protection of vapor corrosion inhibitors that other coatings do not include.

Corrosion occurs when moisture reaches a metal surface and begins the cycle of oxidation and corrosion. VCI coatings provide enhanced protection from this corrosion by creating a tight, mono-molecular protective barrier on metal surfaces. This occurs when VCI ions vaporize and are attracted to anode and cathode points on metal surfaces where they adsorb and create a highly hydrophobic layer (Figure 1). The metal is then protected from the corrosive reaction that would occur if moisture and oxygen were to reach the surface.

Depending on coating type, the barrier also has a measure of self-healing capabilities. If a part of the coating is scratched or damaged during shipping and handling, vapor ions have the potential of attraction to the metal surface to form a renewed protective layer.

Many VCI coatings leave a thin, translucent layer of protection that barely alters the appearance of the product, allowing for easy inspection. These transit coatings protect multiple metals, including aluminum, steel, cast iron, copper alloy and tin-plated steel. They can also be used on painted metal surfaces without damage to the underlying coating (Figure 2). Some show especially exceptional resistance to salt spray conditions and humidity. Transportation coatings can provide protection that far outlasts their shipment period, allowing for six to 24 months of unsheltered outdoor protection, or up to five years of indoor storage protection.

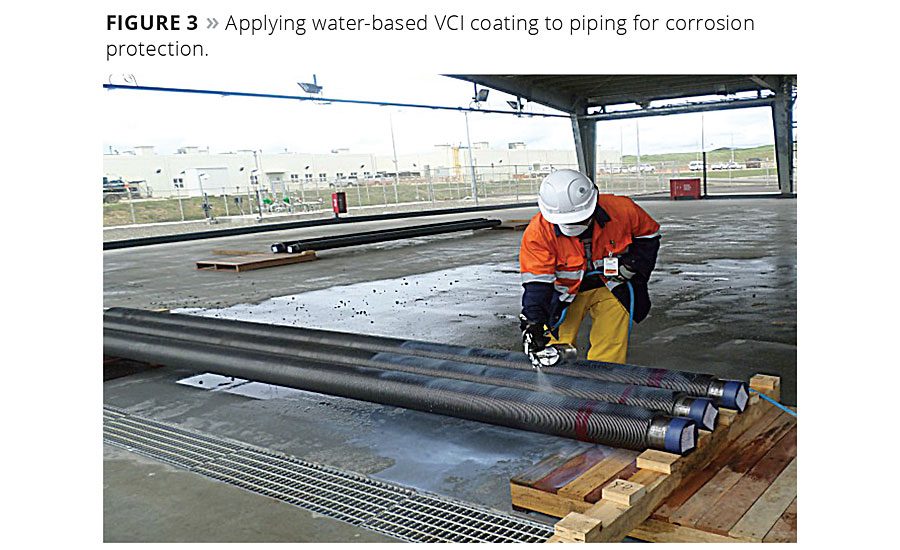

Many VCI transportation coatings are safer than hazardous oil-based coating products (Figure 3). A majority of coatings are water-based, an increasingly preferred type of coating system due to tightening environmental regulations and easier-to-use qualities. Most removable VCI coatings have no or low VOCs. They can be removed fairly easily with an alkaline cleaner.

Some removable coatings that are not water based have measured up to MIL-PRF-16173E specifications for military use -one hard film at Class I, Grade 1 and one soft film at Class I, Grade 2 (Figure 4). These coatings offer short-term transitional protection that can be used on military equipment.

Under Extreme Conditions

VCI coatings have gone through a variety of strenuous tests to evaluate their performance under humid and salt spray conditions, two of the hazardous environments metal parts could be exposed to during shipping (Figures 5 and 6). Some VCI coatings have been known to provide protection for as much as 3500+ hours of salt spray tests and 7000+ hours of humidity.

Salt spray and humidity tests have been performed on VCI coatings according to ASTM standards for producing consistent test results internationally. The harsher of the two tests is ASTM B 117 Salt Spray, during which VCI transit coatings are subjected to highly corrosive situations in a salt fog cabinet. For this trial an odd number of metal panels, such as carbon steel or aluminum, are covered with a temporary coating (an odd number of panels gives a better idea of typical coating performance rather than the uncertainty of a 50/50 split result on only two panels). The panels are air dried for a week and then placed in a salt spray cabinet containing a 5% salt solution. The lab keeps the panels in salt spray until they fail and then compares the extent of blistering or deterioration with ASTM standards. Degree of performance is rated accordingly.

Humidity testing is another evaluation relevant for items being transported or stored for long periods of time and is quite similar to salt spray testing. Coatings are applied to three panels and cured for about one week. They are then hung in a cabinet on a rotating rack and exposed to 100% relative humidity at 120 °F. This conforms to the specifications for ASTM D1748. Coatings are tested until failure occurs, and the resulting blistering/deterioration is compared to ASTM ratings.

When considering that VCI transit coatings have been found to offer protection for a range of 100-3500 hours of salt spray and 100-7000+ hours of humidity, it is worth keeping in mind the intensified nature of testing. Although not an exact ratio, the levels of corrosion that might take a year to achieve under normal circumstances could potentially take place on control samples in only one week (168 hours).

Extreme testing has also been done on some VCI coatings to compare them directly with non-VCI coatings. In one case, a heavy equipment manufacturer requested testing to see how the rust inhibitor used on its equipment compared to the corrosion protection of two VCIs. The non-VCI rust inhibitor was quite similar in viscosity and appearance to one of the VCI coatings but severely underperformed as a rust preventative.

During the test, three carbon steel panels were dipped in corrosion inhibitors -one in the non-VCI liquid and each of the remaining panels in one of the two different VCI removable coatings. They were hung to dry over the weekend and then placed in the ASTM B117 Salt Fog cabinet for 500 hours of exposure. The panels were inspected periodically throughout the test as well as at the end, when final results were photographed. The test found that the non-VCI inhibitor liquid failed within 24 hours of exposure, while the two VCI-coated panels did not fail during the entire 500 hours of testing.

Conclusion

VCI transportation coatings have several advantages for protecting metal parts during shipment and storage. They are more powerful than ordinary coatings, tend to be environmentally friendly and low in VOCs, and are fairly easy to remove. They can be used on either bare metal or painted metal surfaces without harming the substrate. Most importantly, they help protect valuable shipments from rust and corrosion, and have performed effectively under harsh conditions. From many angles, VCI coatings show themselves to be an innovative and effective rust preventive for metal components, whether during stationary or transitory storage. n

Acknowledgements

The author wishes to acknowledge the contributions of Markus Bieber, Rick Shannon, John Wulterkens and Casey Heurung at Cortec Corporation.

References

1 U.S. Department of Transportation. Freight Facts and Figures 2013 http://www.ops.fhwa.dot.gov/freight/freight_analysis/nat_freight_stats/docs/13factsfigures/pdfs/fff2013_highres.pdf.

For more information, visit www.corteccoatings.com.

Report Abusive Comment