A well-formed hydrophobic film that is impervious to water and salts is required to prevent corrosion of painted metal surfaces. One of the most effective ways to ensure that the film is well formed is through the use of coalescing solvents. The ability of a coating to form a protective film becomes more difficult as the amount of coalescent in the coating formulation decreases. At the same time, coatings manufacturers are interested in reducing the amount of volatile organic compounds (VOCs) in their coatings. This trend is driven both by regulation as well as consumer preference.

One way to reduce the amount of coalescent in the coatings is to reduce the minimum film formation temperature (MFFT) of the polymer. The most obvious way to accomplish this is to reduce the glass transition temperature (Tg) of the polymer. Unfortunately, this will also reduce the hardness and dirt pickup resistance of the coatings. Through the use of designed particle morphology and process conditions we have developed a latex that can be formulated into a coating without the use of coalescing solvents that gives excellent corrosion resistance, adhesion to steel, and still is hard enough to give good block resistance and dirt pickup resistance.

Experimental Methods

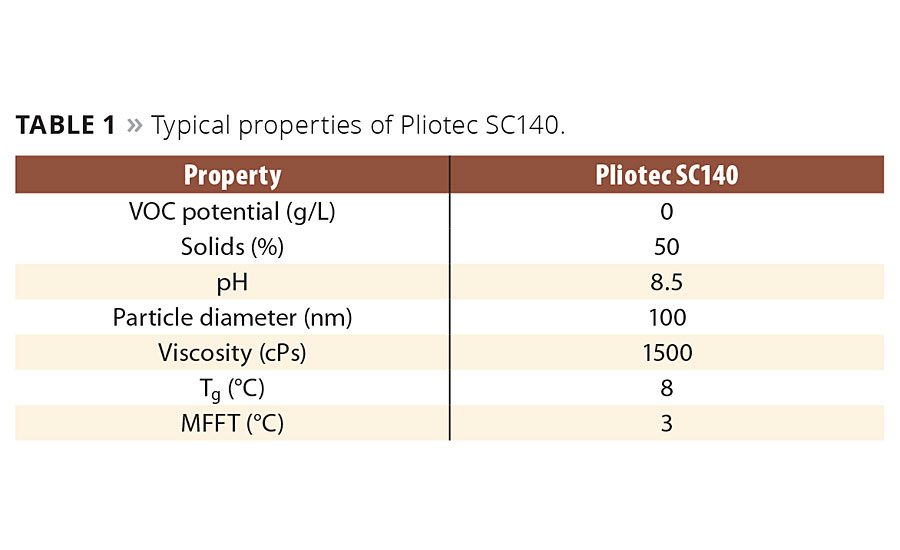

The experimental coating composition employed Pliotec® SC140, which is a self-crosslinking styrene/acrylic latex. The typical properties of the latex are given in Table 1.

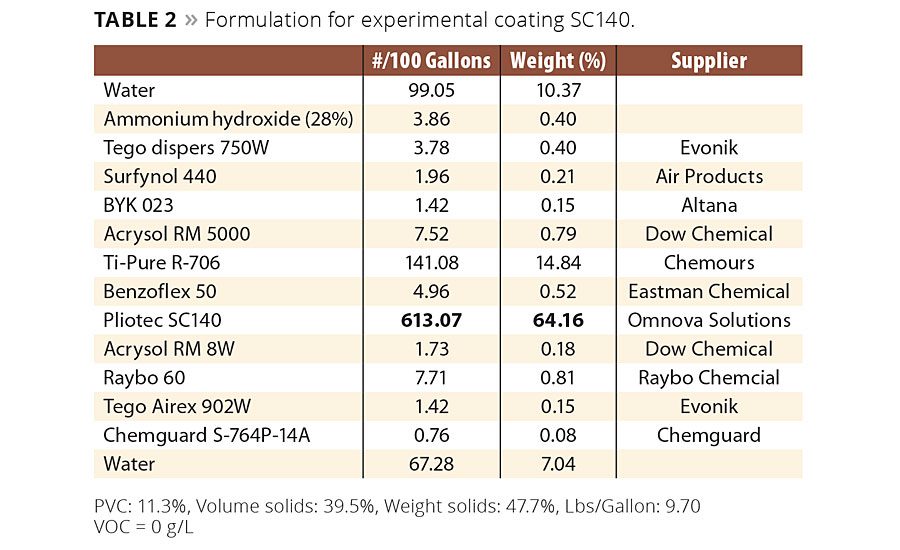

Pliotec SC140 was formulated into an experimental coating using a high-speed disperser fitted with a Cowles blade. Typical paint making procedures were followed to make the coating. The formulation for the experimental coating can be found in Table 2.

The Pliotec SC140-based experimental coating was evaluated against six commercial controls marketed as direct-to-metal (DTM) coatings that require no primer. The wet paint properties are in Table 3. The experimental coating is designated “SC140”, while the commercial coatings are designated “CPX”, where X refers to the number of the coating.

The commercial coatings range from 0 to less than 250 g/L of VOC. The volume and weight solids of all of the coatings tested are similar, while there is a fairly wide range of viscosities, ranging from 81 to 118 KU.

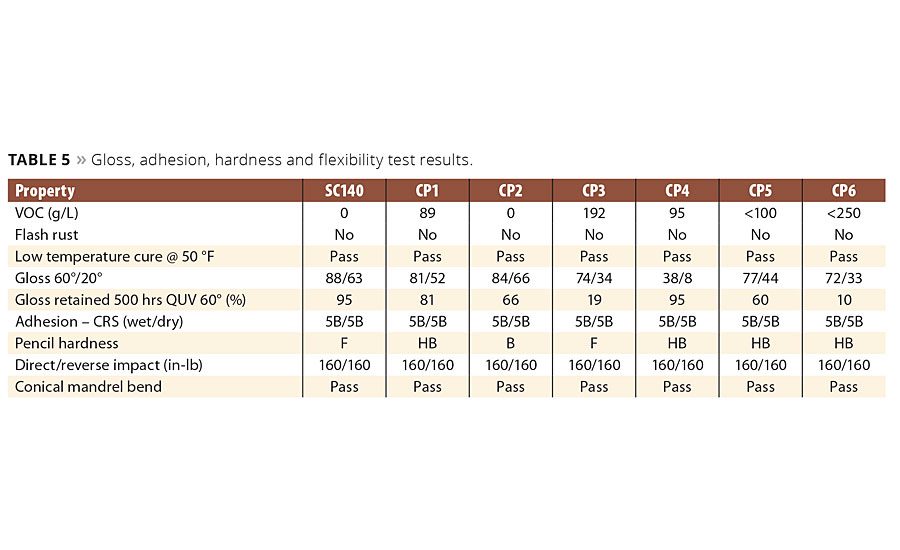

Gloss was measured using a micro-TRI-gloss glossmeter, following ASTM D523. The average of three measurements was recorded for each angle.

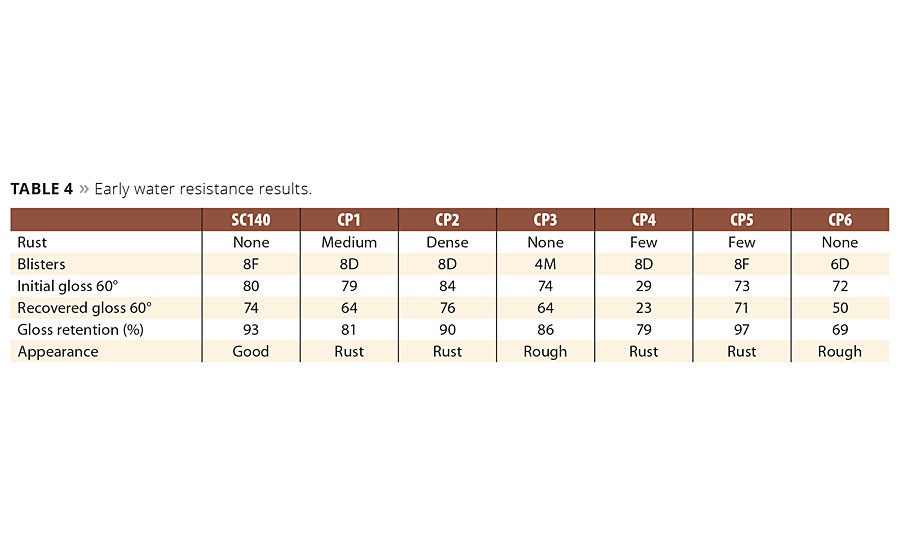

Early water resistance was tested on the coatings. For this test the coating was applied to a cold rolled steel panel using a 10 mil applicator bar. The coating was allowed to dry for 4 hrs under ambient conditions. The back, edges and bottom of the panel were taped and the panel was suspended in water overnight. The following morning the panel was removed from the water and rated for blisters, rusting and loss of gloss. The ability of the coating to recover was also noted.

Adhesion was measured on cold rolled steel panels. The coating was applied using a 15 mil applicator bar. The coating was allowed to dry 1 day under ambient laboratory conditions and then the adhesion was measured according to ASTM D3359. The coating was also tested after 7 days under ambient laboratory conditions.

Impact resistance was measured on an anodized aluminum panel coated using a 15 mil applicator bar. The coating was allowed to dry for 1 week under ambient conditions and then tested according to ASTM D2794 using a 4-lb weight dropped from various heights.

The flexibility of the coating was measured using the Conical Mandrel Bend Test, ASTM D522 Method A. This testing was also done on an anodized aluminum panel coated using a 15 mil applicator bar. The coating was allowed to dry for 1 week and then placed in the testing apparatus, coated side facing away from the mandrel. The panel was then bent. The coating passed if there was no cracking or delamination of the film.

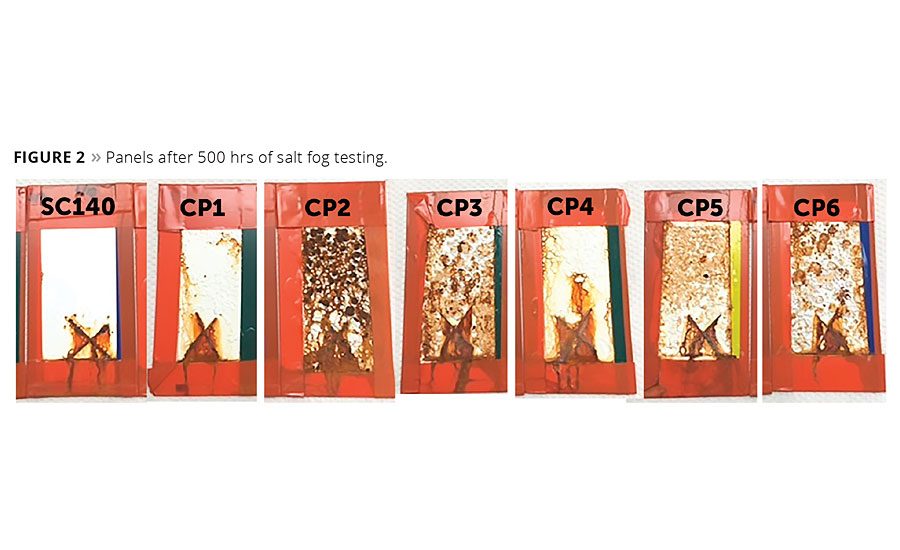

Corrosion resistance was determined by evaluating blistering and rusting after 500 hrs of salt fog testing. A cold rolled steel panel was coated using a 15 mil applicator bar to give a dry film thickness of 2.8 to 3.2 mils. The coating was allowed to dry for 1 week under ambient conditions. An ‘X’ was scribed into the coating and the panel was taped to cover all noncoated areas. The panel was then placed into a Q-Fog salt spray cabinet for 500 hrs of constant spray with a 5 weight% NaCl solution. After 500 hrs the panel was removed and rated. The size of the blisters was recorded as a numerical value from 2 to 8, with 8 being very small and 2 being very large. The amount of blistering was recorded with a letter meaning F (few), M (medium), MD (medium dense) or D (dense). A panel with a couple of small blisters would be rated 8F, while one that is covered in large blisters would be rated 2D. The amount of rusting was also recorded using the above scale for the amount of blistering, so very little rust would be recorded as F while heavy rusting would be D.

Gloss retention was measured after 500 hrs in a QUV accelerated weathering tester. For this test the coating was applied to an anodized aluminum panel using a 15 mil applicator bar. After the panel was allowed to cure for 1 week under ambient conditions the gloss was measured. The panel was taped to cover all noncoated areas and then placed in the QUV cabinet. The weathering cycle was 8 hrs of UV, bulb A, at 60 °C followed by 4 hrs of condensing humidity at 50 °C. After 500 hrs the panel was removed and the gloss was measured again.

The hardness of the coating was measured by the Pencil Hardness Test, ASTM D3363. The coating was applied to an anodized aluminum panel using a 15 mil applicator. The coating was allowed to dry for 1 week and then the hardness of the coating was measured by scratching the surface of the film with various pencils of different hardness. The hardness is recorded as the hardest pencil which does not remove the coating.

The ability of the coating to form a film at low temperatures was determined by coating a sealed Leneta Card using a 10 mil applicator. The panel was placed in a Tenney Box set at 50 °F and 50% relative humidity overnight. The quality of the film formation was determined the next morning.

To evaluate the dirt pickup resistance of the coating a cold rolled steel panel was coated using a 15 mil applicator bar to give a dry film thickness of 2.8 to 3.2 mils. The coating was allowed to dry for 1 week under ambient conditions. An ‘X’ was scribed into the coating and the panel was taped to cover all noncoated areas. The panel was then placed onto the test fence at a south 45° orientation. The panels were taken down and graded for dirt pickup and corrosion resistance quarterly.

Results and Discussion

The early water resistance test is meant to simulate an article being painted then placed outside, where it might be subject to rain before the coating has been able to completely cure. The majority of the commercial coatings had heavy blistering and some rusting when the panels were removed from the water following the overnight soak. The Pliotec SC140-based experimental coating had slight blistering, but no rusting.

The panels were re-examined after allowing them to recover overnight. The data is contained in Table 4. The blistering was completely gone from the experimental coating. The commercial coatings all contained rust, blisters or both. All of the coatings had also lost gloss after the immersion and recovery. The Pliotec SC140-based experimental coating retained 93% of its initial gloss. The gloss retained ranged from 69% to 97% for the commercial coatings. The appearance of the coatings was also recorded. The photographs in Figure 1 show the panels after recovery. Panels CP1, CP2, CP4 and CP5 all contain rust. Panels CP2, CP3 and CP6 all had a rough surface from the blisters that remained. Only the Pliotec SC140-based experimental coating had a good appearance.

Table 5 contains the data from the evaluation of the coatings. Each of the coatings did not flash rust and all were able to form a good film at 50 °F. The ability to form a film at lower temperatures becomes more difficult as the VOC of the coating decreases.

The coatings all had an acceptable level of gloss, except for CP5, which was labeled as a semigloss rather than high-gloss paint. The gloss was also measured after 500 hrs in the QUV chamber. The Pliotec SC140-based experimental coating retained 95% of its original gloss, while the high-gloss commercial coatings only retained between 10% to 81%. The semigloss coating also retained 95%, but from a much lower starting value. Since the QUV weathering test is a proxy for actual exposure we would expect the commercial coatings to lose gloss much faster than the experimental coating. The experimental coating should look newer, longer.

As would be expected for products being sold as direct-to-metal coatings, all of the coatings had excellent adhesion to cold rolled steel. All of the coatings also passed the 160 in-lb direct and reverse impact resistance and the conical mandrel bend. The commercial paint CP2, which was also a zero-VOC coating, was the softest with a B pencil rating. The remainder of the commercial coatings had a pencil hardness of HB, except for CP3, which had a pencil hardness of F. The experimental coating also had a pencil hardness of F. CP3 had a VOC level of 192 g/L while the experimental coating was at 0 g/L. The Pliotec SC140-based experimental coating gave a harder film than any of the less than 100 g/L coatings.

Corrosion resistance testing also showed significant differences between the experimental coating and the commercial coatings. The Pliotec SC140-based experimental coating was made without the use of corrosion-inhibiting pigments. The pictures in Figure 2 show the coatings after 500 hrs of salt fog testing on cold rolled steel.

The dry film thickness of the coatings varied from 2.8 to 3.2 mils. As can be seen in both the pictures and the data in Table 6, the Pliotec SC140-based experimental coating had significantly better corrosion resistance than any of the commercial products. This was especially true in the field, where the difference in appearance was dramatic.

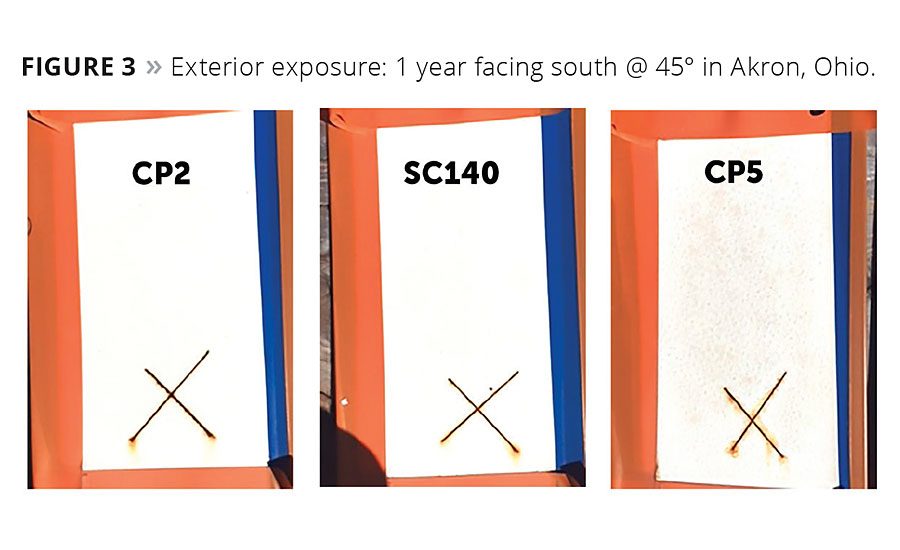

The Pliotec SC140-based experimental coating was also placed on the test fence in Akron, Ohio. The commercial coatings CP2 and CP5 were also exposed. The test fence was orientated south and the panels were at 45°. Figure 3 shows the panels after 1 year of weathering. CP5, which was formulated at less than 100 g/L of VOC, looked quite bad after 1 year of aging. There is a fair amount of rust on the scribe, and the panel had blistered extensively. CP2 and the experimental coating both looked reasonably good in contrast. These were both zero-VOC coatings. The experimental coating had slightly better corrosion resistance in the scribe area, but the dirt pickup was similar in both cases.

Conclusions

We have shown that a coating made using Pliotec SC140, which was formulated without the use of coalescing solvents and contains 0 g/L of VOC, can give excellent corrosion resistance, very good early water resistance and good overall properties for a DTM coating. These results were obtained without the use of corrosion-inhibiting pigments. Compared to commercially available DTM coatings, some formulated up to 250 g/L of VOC, the Pliotec SC140-based experimental coating had excellent corrosion resistance both in the salt fog chamber as well in exterior exposure.

By Richard Flecksteiner, Terri John and Cassandra Giorgio, OMNOVA Solutions, Beachwood, OH

For more information, call 216.682.7082 or visit www.omnova.com.

Report Abusive Comment