Packaging and transporting flammable and hazardous chemicals continues to be a concern in the paint and coatings industry. This is commonly known as transportation of dangerous goods (TDG). When it comes to packaging flammable and hazardous chemicals, metal packing has gained a proven record over other packaging materials by attaining the highest UN (United Nations) ratings compared to cost. This makes metal packaging the preferred packaging product for the industry.

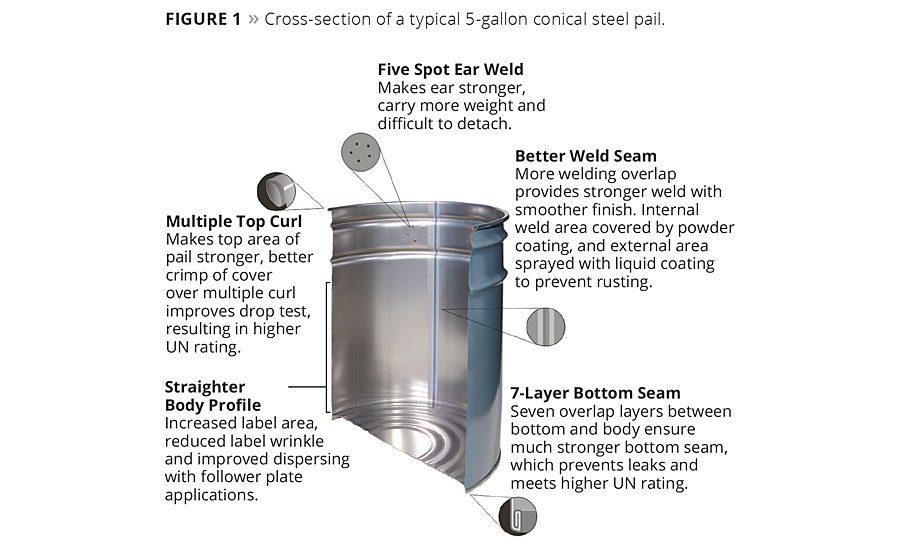

While paint and coatings manufacturers continue to compete to formulate products with the lowest volatile organic compound (VOC) content possible, metal packaging manufacturers are vying for the highest UN-rated steel pails within the metal packaging industry. This is possible thanks to newer manufacturing technologies that allow manufacturers to make steel pails with triple-seam bottoms (seven overlap layers) and double-curled tops, along with better side seam welds. Traditional methods involved double-seam (five overlap layers) bottoms and single-curled tops of the conical steel pails.

Figure 1 shows a schematic drawing of the triple-seam (seven layers) bottom and double-curled top of a typical 5-gallon conical steel pail. Triple-seam bottoms and double-curled tops provide the required strength while keeping the steel gauge low to survive an internal hydrostatic pressure test of 100 kpa and a drop test of as high as 2.5 meters. This allows paint and coatings manufacturers to package materials as high as 2.5 specific gravity on Y-rated (medium-hazard) materials and 1.7 specific gravity on X-rated (high-hazard) materials.

UN-rated steel pails are available in many sizes, both in open-head configurations (conical shape) with removable covers, as well as tight heads with non-removable tops. Steel pails are also 100% recyclable and contain 25% post-consumer content.

For more information, visit www.alliedcans.com.

Report Abusive Comment