Chemical companies play critical roles in developing best practices in risk mitigation and crisis management - with industry initiatives such as Responsible Care demonstrating this drive to continually improve protection for people and the environment. In early 2016, the U.K.’s National Chemical Emergency Centre (NCEC) hosted a forum on supply chain best practices with representatives from influential private sector partners at the forefront of industry. The forum provided an opportunity for product and transport safety managers, and Safety, Health, Environment and Quality (SHEQ) executives to network, share best practices on day-to-day chemical safety and offer insight into improving safety across the sector.

Topics of discussion were put forward by the delegates and chosen for their relevance and timeliness in the context of the current demands facing industry. These included:

- Delivering best practices in product stewardship across the supply chain;

- Meeting requirements for global chemical emergency response;

- Emergency response and incident management in cases of off-site emergencies;

- The benefits and risks of implementing chemical safety benchmarks.

In attendance were managers from major companies and stakeholders across the chemical industry, representing areas such as petrochemicals, agrochemicals, polymers and plastics. This included representatives from Allnex, Ineos (O&P Europe), Shell Chemicals (Europe BV), Yara and CEFIC. The total annual sales revenue of those that attended is over $120bn and accounts for almost 10% of the sales for the world’s top 120 chemical companies.

This article explores some of the outputs from these discussions with practical tips for companies to implement best practices in chemical safety across the supply chain.

Best Practices and Challenges

Building a culture of risk mitigation and management into the chemical supply chain to reduce the probability of an incident or its impact on people or the environment is a priority for responsible managers.

The delegation identified managerial support and hunger for excellence in risk management as a core ingredient and first step to implementing best practices. To achieve this, the group highlighted the importance of supporting front-line supervisors in logistics to develop leadership skills to match their technical expertise. They also discussed the need to embed a culture of risk mitigation throughout the supply chain by building long-term relationships with chemical suppliers and distributors, and supporting them to make achievable improvements in chemical safety.

In discussing the challenges facing industry, one key issue was a concern that smaller chemical companies may lack the knowledge, capacity or infrastructure to consistently deliver best practices. The European Commission has already flagged this as an area of concern, particularly in relation to the upcoming REACH 2018 registration. Similarly, managing the risk of third-party hauliers collecting or dropping chemicals onsite is complicated due to the difficulty determining the quality of external equipment or training processes. Companies must also be prepared for the risks of chemicals in ‘mixed-load’ trucks and ensure that all employees adhere to the rigors of the Accord Dangereux Routier (ADR) at every step of the supply chain.

The delegation then highlighted the practical actions companies can take to ensure that suppliers and distributors uphold this high standard. This included the need to perform assessments of customers and distributors of high-risk chemicals through full-system exercises with well-defined objectives and embedded learning to build safety into a chemical’s supply chain. Techniques used to achieve this include:

- Providing driver training;

- Performing supply chain spot checks;

- Maintaining detailed training records and incident logs;

- Conducting periodic route reviews with route planning and live route assessment and changes for high-hazard products.

Many companies supported this process with positive incentivizing actions, such as offering driver of the year awards. Establishing standards in procurement and performing impartial third-party assessments are valuable tools to identify gaps in competency, procedures and systems, and ensure that high-quality systems are in place. Meanwhile, professional on-site, in-person or online assurance training sessions are essential for all employees handling dangerous goods.

Managing the Approach to Global Emergency Response

For the international companies at the forum, 24-hour emergency response formed an important pillar of their chemical safety framework.

Attendees agreed that using European standards as a basis for emergency response is a good start when it comes to defining best practices. However, the lack of harmonized regulations creates challenges, despite the almost worldwide GHS implementation. Different regional definitions for the practical application of best practices also demands precision in interpreting regulation. Companies must therefore ensure that their processes are aligned with regional legislation.

The relative lack of training in chemical incident response for local partners and the fire and rescue services in emerging regions was also highlighted as a key concern for companies operating in remote geographies. Delegates expressed the need to engage with local fire services, and encouraged chemical companies to build relationships and, where appropriate, share experience with regional emergency responders on best practices in emergency response. Finally, without direct visibility on the ground, 24-hour multilingual emergency response remains the first and most immediate line of protection for populations and the environment in the event of an incident.

Dealing With the Issues of Off-Site Emergency Response

Delegates were asked to draw up what they considered to be best practices in preparing for an off-site emergency. They discussed preparations for the full crisis management lifecycle, from testing current methodologies to preparing for media response. Recommendations included:

- Scheduling four to six table-top exercises a year that test methodology and communications routes, including third parties to impart risk mitigation best practices and test subcontractor capabilities and call-flow processes between parties.

- One in-depth ‘in-the field’ exercise per year using operational equipment and involving all partners and emergency response personnel.

- Testing and developing leadership in decision making through crisis management workshops and activities. In particular, drawing clear boundaries for senior managers for when organizations should respond and where they should support partners and emergency service response. This involves educating senior managers how to empower response teams.

- Implementing crisis communications systems and procedures with plans to overcome language challenges, which is essential for those operating internationally.

- Clear understanding with contractors and logistics providers about who is going to take responsibility in different incidents.

- Ensuring that all relevant stakeholders have access to simple procedures to follow and checklists of key activities in case of emergency – generally business continuity plans are too long, and not action orientated and accessible for those using them.

- Press training for spokespeople and identifying points of contact for media enquiries.

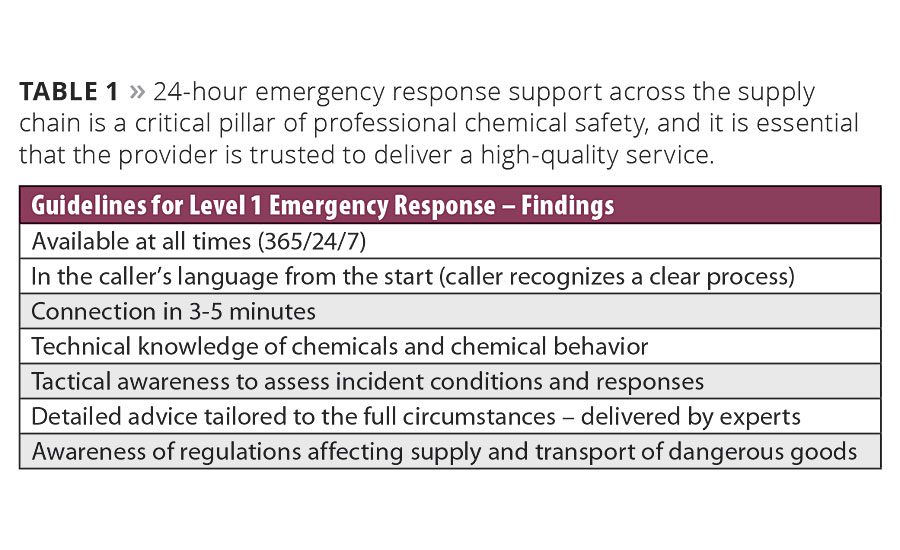

The group concluded that success in off-site emergency response requires comprehensive training programs with well-defined learning objectives. This includes delivering pre-activity risk assessments, identifying local responders in advance, providing in-country employee training and offering auditable web-based training platforms. For many companies, employing a trusted third-party training partner is a cost-effective way to provide comprehensive supply chain training. Finally, delegates discussed what guidelines they might provide or produce for the provision of a comprehensive level 1 emergency response service (Table 1).

What Role Do Benchmarks Play?

The delegation agreed that standards play an important role in establishing best practices, providing something against which to measure performance, helping to educate supply chains and raising standards, both internally and externally. When commenting on what sets apart good standards, the group agreed that those developed through the collaboration and involvement with trade associations, experts and industry bodies have a greater degree of legitimacy. CEFIC loading/unloading guidance was highlighted by the group as an example of a guideline that was performing well, in part due to close industry involvement.

However they also noted a number of risks and concerns when it came to creating benchmarks in best practices, in particular low-cost drivers. In the classification of materials hazards there also remain inconsistencies between organizations, with a perceived short-term disadvantage to those following best practices. Finally, identifying how to embed guidelines with local emergency responders so they make the right decisions when faced with an incident remains a challenge for the chemical industry as a whole, highlighting the importance of close public sector engagement.

Summary

NCEC exists to help those working in the chemical industry to provide the highest level of protection to people, property and the environment. However, if best practices are to be widely implemented they must be practicable, and developing practical benchmarks can only be achieved through close industry consultation. The annual practitioner forum provides a unique opportunity to review the challenges facing industry while working to continuously improve processes that ensure the safety of people, property and the environment across the global supply chain. NCEC is delighted to disseminate these results to help organizations benefit from the combined learning and experience of the forum and promote best practice activities that really work.

To be part of the dialogue and share your experience in chemical safety with industry experts from around the world, register to attend NCEC’s next private sector forum. Contact daniel.haggarty@ricardo.com for more information.

For more information, visit http://the-ncec.com/.

Report Abusive Comment