Coatings chemists and paint formulators face the challenge of developing products that are not only durable and aesthetically pleasing, but that address sustainability issues and have added functionality. The technology of infrared-reflecting (IR) pigments addresses both sustainability and the desire for functionality by allowing the development of coatings that can reduce energy usage and meet building code-related certifications and requirements. There are three main classes of IR pigments that work with different mechanisms and can be utilized individually or together for maximum performance. This article is meant as an introduction into the fundamental properties of the pigments to better understand how they can be used in fully formulated products.

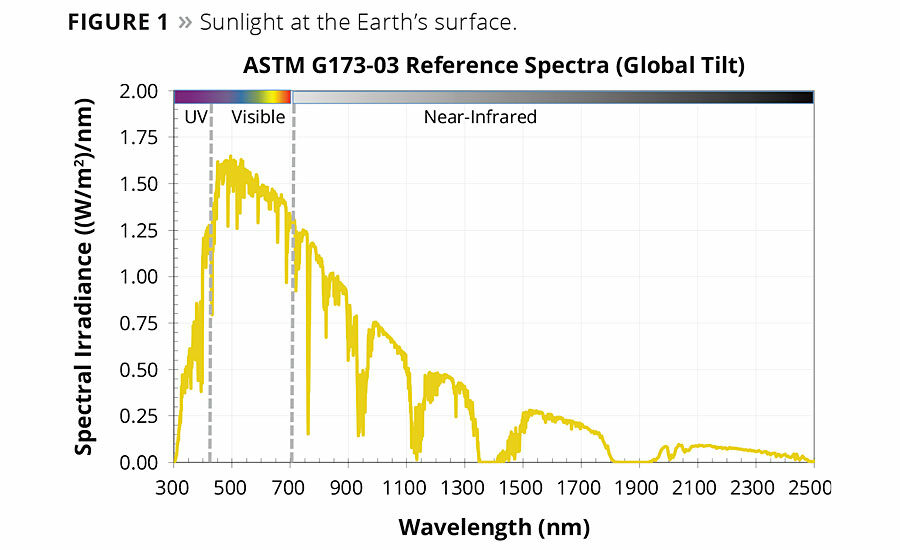

First, a basic understanding of the complete solar spectrum is needed. Standard coatings are primarily concerned with color, which is determined by the visible, and the ultraviolet (UV) wavelengths of light, which impacts the durability of a paint or coating. The near-infrared (n-IR) part of the solar spectrum is often ignored. The UV (295-400 nm) spectrum is only a small percent of the sun’s energy, with the rest divided up roughly in half between the visible (400-700 nm) and the invisible near-infrared (700-2500 nm) spectrums.

An example of the distribution can be seen in Figure 1. This is roughly the black body radiation distribution of a 5,800 k body, but with reductions for the absorbances in our atmosphere.

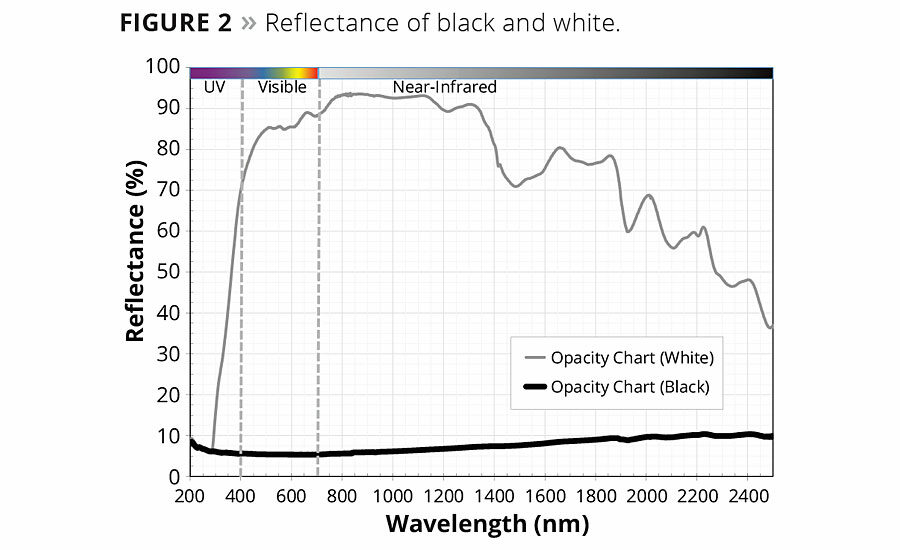

The importance of this illumination spectrum can be seen when we compare it to the reflectance spectra for a black and white color. Figure 2 shows the reflectance curves for the white and the black portion of an unused drawdown card commonly used to test coatings color and opacity and the substrate used in these experiments. The white portion reflects (does not absorb) light back in the visible part of the spectrum and keeps on reflecting back into the n-IR range. A standard black made of carbon black absorbs (does not reflect) in the visible wavelengths and keeps on absorbing into the n-IR portion of the spectrum. We all know that a white object stays cooler than a black object when exposed to the sun. People often prefer dark, more saturated colors that are perceived to be more aesthetically pleasing than a stark white object. The optimum would be a material that has the absorption in the visible for darker colors but reflects in the invisible n-IR to remain cooler.

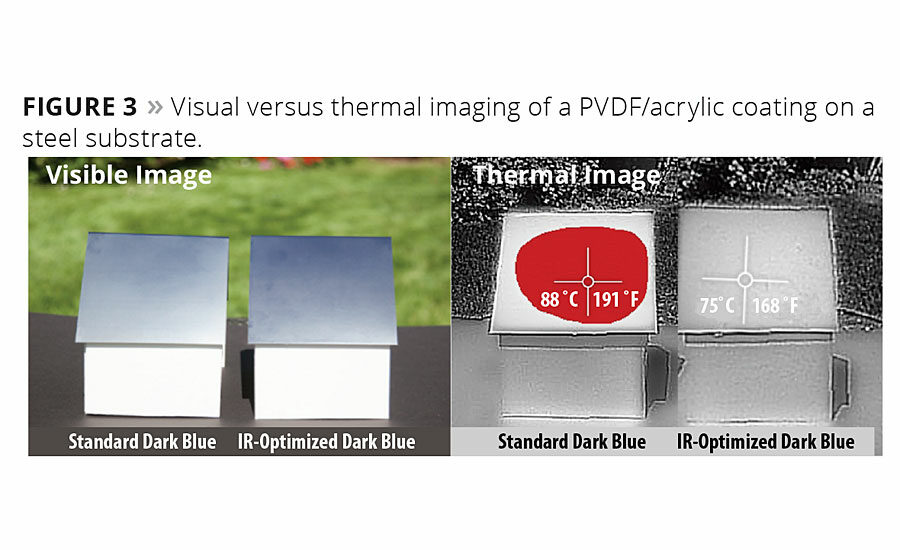

An example of how this works can be seen in Figure 3. The images both show two model houses. Both houses have a PVDF/acrylic coating over a steel substrate. While both sets of houses are the same dark blue visual color and are visually indistinguishable from each other, the thermal imaging picture can sense the temperature of the two roofs when they are exposed to the sun on a summer day. The roof on the left is made with standard pigments and the roof on the right is made with IR pigments. The temperature difference is due to the roof on the right reflecting the invisible n-IR energy, which allows it to stay cooler.

The ability of a material to reflect the sunlight over the whole solar spectrum is called the Total Solar Reflectance (TSR). In the example of the opacity chart, the white portion has a TSR of 83% (0.83) and the black portion has a TSR of 6% (0.06). With the two roof models that are the same visible color, the standard roof’s TSR is 8% and the IR Pigment roof is 28%. This 20% difference in TSR gives the roofs on this summer day about a 13 °C (23 °F) difference. The surface temperature difference is driven by the TSR difference but is affected by the object’s orientation to the sun, ambient temperature and air flow over the roof due to wind. This temperature difference on the surface can lead to less heat being transferred to the interior of the building (depending on construction), where it then has to be removed by energy-intensive HVAC systems. Besides the potential for overall reduction in energy usage, the reduced demand for HVAC energy can lead to less peak-energy demand, which is very costly to produce and plan for on an energy grid. The key is that this technology allows people to have the same customary roof colors without sacrificing aesthetics by going purely to white.

There are three different pigment technologies that fall in the IR pigment family. They are:

- Inorganic IR-reflecting black;

- Organic IR-transmitting black; and

- IR-optimized titanium dioxide.

All three of these technologies can be used to reduce the temperature of colored materials relative to standard pigments, and their performance can be optimized by using the pigments in combination.

Inorganic IR-Reflecting Black Pigments

Inorganic IR-reflecting black pigments form the core of the IR pigments in use. They are classified as CI Pigment Brown 29 and are part of the CICP (Complex Inorganic Color Pigments) family. These pigments are the standard in building materials when simple oxides like iron oxide are too limiting coloristically and the organic pigments are not color stable enough. The IR property is inherent in the pigment chemistry and will not degrade or migrate over time. These pigments have been used for their IR properties since the 1980s to reduce the solar heat-induced warping of rigid PVC in windows and siding. In the late 1990s they were the major technology used in “cool roofing” products for the EPA Energy Star program. They have also been used in vinyl seat covers in India to keep the motorbike seats cooler and more comfortable while having a longer life span.

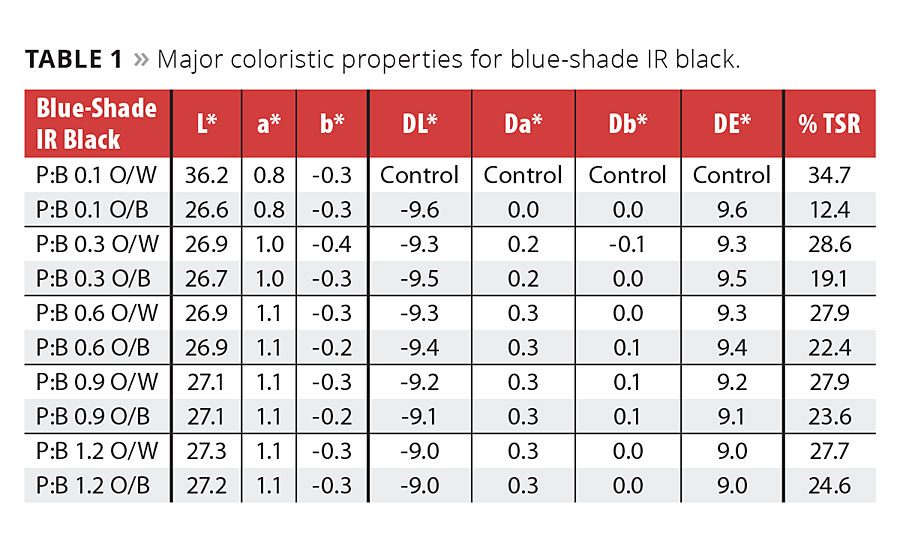

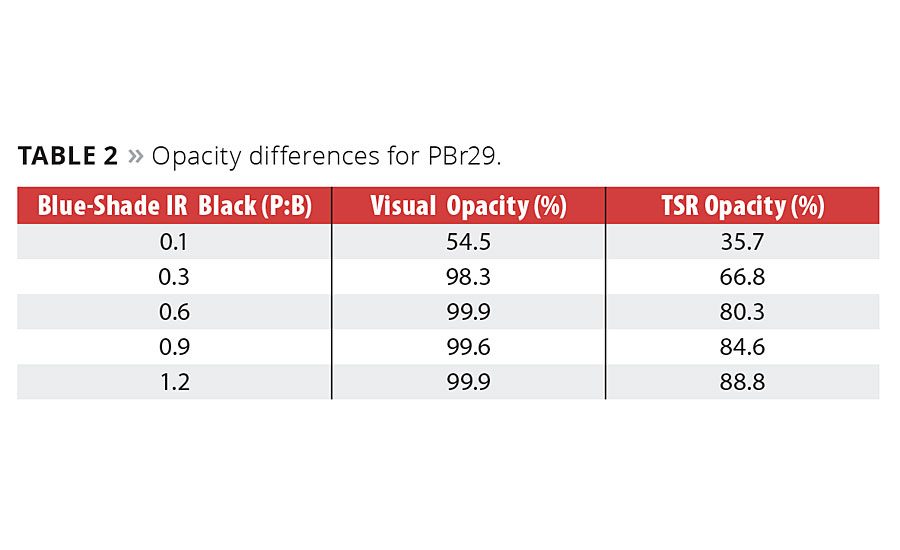

The major coloristic properties for a blue-shade IR black can be seen in Table 1. The PBr29 in masstone when tested in a solventborne acrylic resin system over the previously mentioned black and white test panel with a DFT of 2 mils/50 microns gives a dark L* value, low a* and a negative b* value. The P:B (pigment:binder w/w) ratio was varied from 0.1 to 1.2 to show the hiding power of the pigment. As can be seen in Table 2, the PBr29 gains full opacity between a P:B of 0.3 and 0.6. Interestingly, the masstone L* value has a minimum in this range also (Table 1). When the P:B is increased the masstone L* increases slightly. This is probably due to PBr29’s high refractive index bringing some scattering to the visible and overpowering the absorption.

While the PBr29 has gained visual opacity by around P:B=0.4, these films are not yet IR opaque. By taking TSR readings over the black portion and the white portion coated with the different P:B loadings, there is a difference in the TSR readings. This difference can be expressed as a ratio of the TSR over black to the TSR measured over the white. This TSR opacity takes into account the complete solar spectrum, not just the ratio in the n-IR.

TSR over black

TSR Opacity= -------------------------

TSR over white

The TSRs for each coating film panel were measured and the TSR opacity differences calculated (Table 2).

The reason for this small difference in visual opacity and larger difference in TSR opacity can be explained by looking at Figure 4, which shows the reflectance curves for each coated panel, measured over white and over black. The solid black lines represent reflectance over the black portion of the panel and the dashed lines represent reflectance over the white portion. Higher loadings of pigment are denoted by thicker lines. The vertical axis shows how much of the sun’s energy the coating is reflecting at each wavelength. The low-loading P:B=0.1 panel has a difference in reflectance in the visible, showing the lack of visual opacity. All the other loadings have their visible reflectance curves overlapping, denoting that the coatings are visually opaque. Once past the 700 nm range, the curves diverge. The highest loaded coatings show the smallest difference; it can be seen that there is still a substrate effect.

Looking at all the values, we can see that the optimum coating for color and TSR would be about a P:B=0.4 over a white substrate. If that same coating were to be applied over a more absorbing substrate, then the TSR reading could be almost 9% lower. If the substrate to be covered is unknown, or known to be absorbing in the IR, increasing the P:B will lead to higher TSRs.

The reason for this difference in visual and IR opacity is that while they are generally referred to as IR-reflecting pigments, they are actually scattering the n-IR light. Since the coloring mechanism in the visible spectrum is a fairly strong absorption, it exerts its influence faster than the weaker scattering mechanism in the IR. Since the IR range is largely scattering, with only a small absorption, the light can transmit through the film until the P:B ratio is high enough. While it may not be commercially viable, the low oil absorption and resin demand of the PBr29 IR blacks is low enough that P:B ratios can be pushed to 2.0:1 and still have fairly high gloss and good leveling.

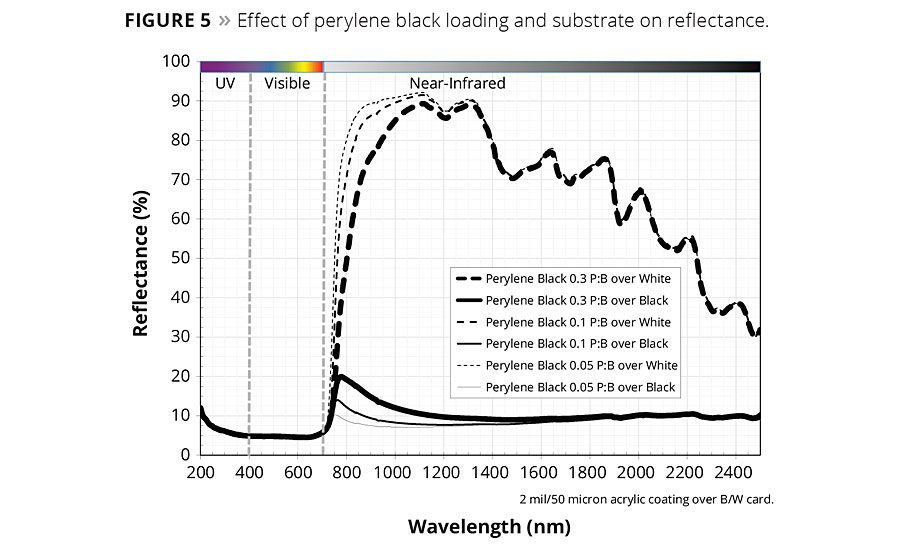

While the PBr29 pigments have IR scattering properties, the perylene black (CI Pigment Black 32) pigment has no appreciable IR scattering and relies on IR transmittance to achieve high TSRs.

Organic IR-Transmitting IR Blacks

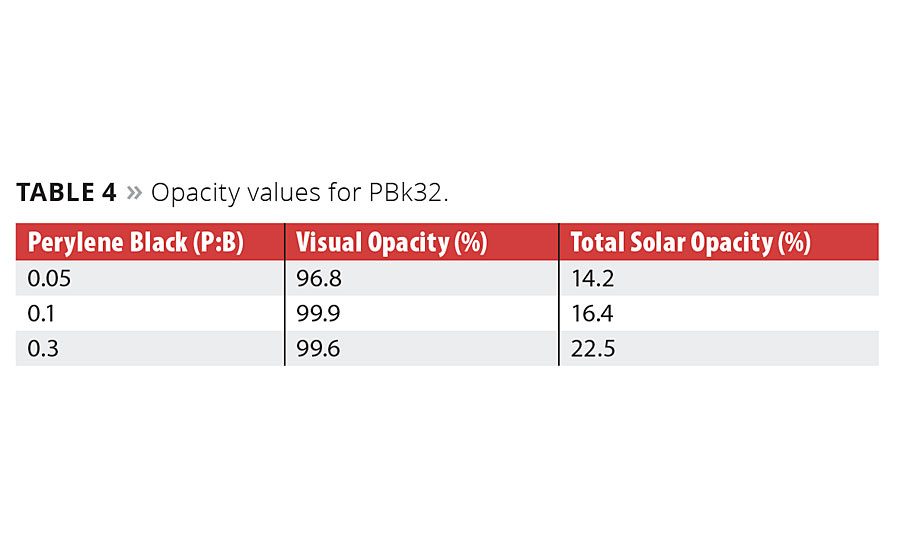

This behavior can be seen when looking at the reflectance curves for PBk32 coating following similar testing as the PBr29. The PBk32 is an organic pigment with strong absorbance in the visual, even at low P:B loadings. This can be seen in Figure 5 where all the lines are on top of each other in the visible region. In the n-IR region, the lines diverge just past the visible n-IR frontier at 700 nm. The coating measured over the white portion shows very high reflectance, while the films measured over the black substrate show very low reflectance. This shows that the PBk32 has very little scattering ability in the n-IR region.

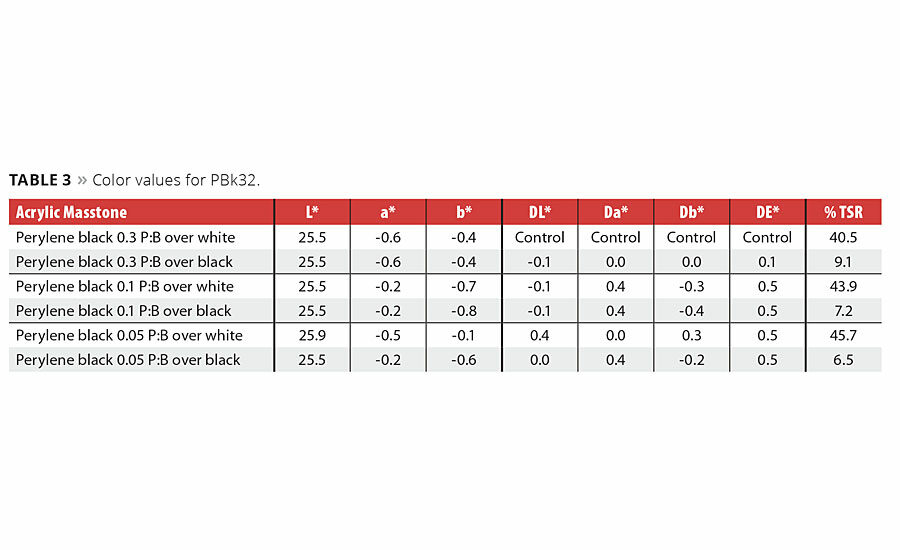

Coloristicly, the PBk32 masstone gives dark, low L* values and a negative b* value. It does have a negative a* value for a slightly green hue (Table 3). As can be seen in Table 4, the PBk32 gains visual opacity quickly, but the IR opacity never rises very high. These visual and IR properties can be used to create dark colors with high TSRs. It can be seen that a P:B= 0.1 would give visual opacity and a TSR over 40. The main issue with the PBk32 is that it is organic in nature and generally not as inherently durable as inorganic pigments. This is especially relevant for coatings that are designed for exterior use in building products. The most critical issue is that if the coating is over any substrate but an IR-reflecting one, the TSRs can be very low. The PBk32s also have a tendency when marred to switch to a reddish hue. This manifests itself if the coating is roughly handled and abraded. A simple test for the presence of PBk32 is to rub a coin on the surface of a coating.

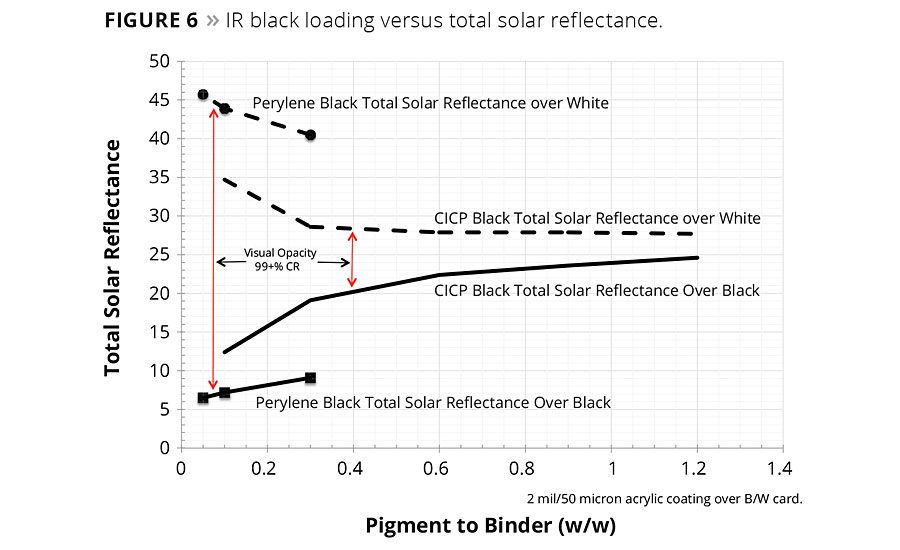

Figure 6 examines the relationship between pigment loading for the two IR black pigments over different substrates. The TSR measurements for the PBr29 and PBk32 were plotted on the vertical axis versus the P:B ratio for each along the horizontal axis. The difference in loading here is exaggerated because of the difference in the specific gravity of the two pigments (1.5 vs 4.9). The solid lines represent the coating over the black portion of the card, and the dashed line represents the coating over white. Where each pigment gains visual opacity is marked by a red arrow. What can be seen in the chart is:

- PBk32 gains visual opacity at a lower P:B ratio;

- The difference for the PBk32 when over black or over white is larger than for the PBr29;

- PBk32 will give higher TSRs if the coating is over white;

- PBr29 will give higher TSR if over an absorbing substrate;

- TSR can be maximized by optimizing pigment loading for visual and IR opacity.

Because of the difference in oil absorption, the PBr29 can be loaded at a higher level to reduce the effect of substrates on TSR without compromising coating properties.

Black Rainbow of Options

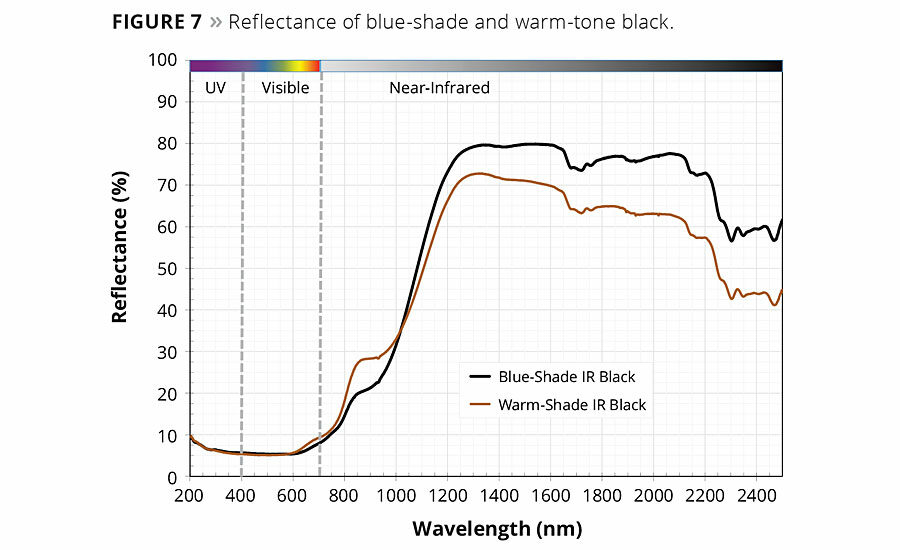

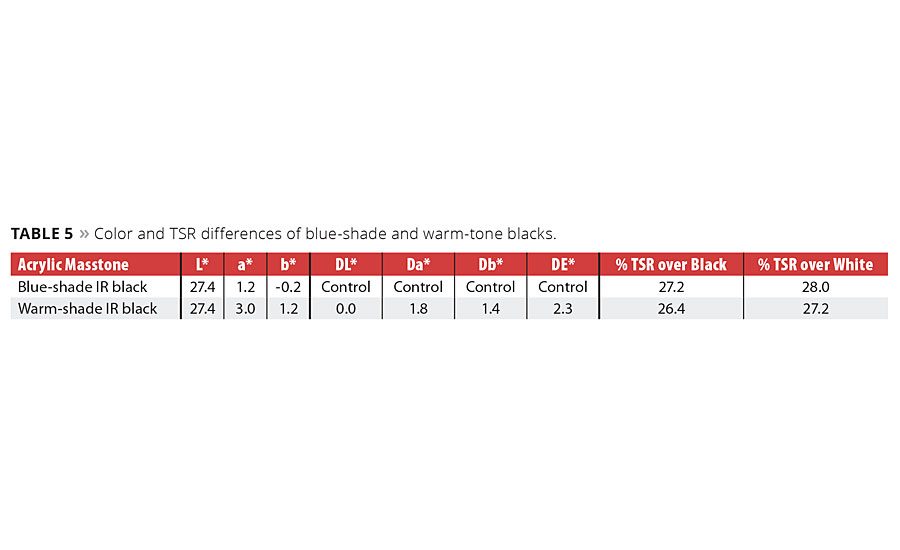

The PBr29 IR pigments come in a range of different versions. The three main properties of an IR black are the masstone jetness (measured by Ma* value), TSR and tint strength (measured by TL*). These properties are driven by pigment chemistry, particle size and other factors so that all three properties become a balancing act. This leads to a range of products, or a ‘Black Rainbow’ of options for the paint and coatings developer. The most apparent difference is the masstone color. For comparison sake, two major subdivisions in the PBr29 products have their reflectance curves plotted against each other in Figure 7. Both pigments have good absorptions in the visible part of the spectrum, but the warm-toned version has a slight increase in reflectance near the transition between visible and the n-IR around 700 nm. The reflectance curves in the n-IR differ slightly due to the optimization for specific balance of properties.

The color and TSR differences were measured quantitatively in the visible and overall TSR and put into table form (Table 5). These panels were run at a PB=1.2 at a film thickness of 5 mils (125 microns). In the masstone, both panels have low L* values but the warm-toned black has higher a* and b* values. Both pigments have high TSRs.

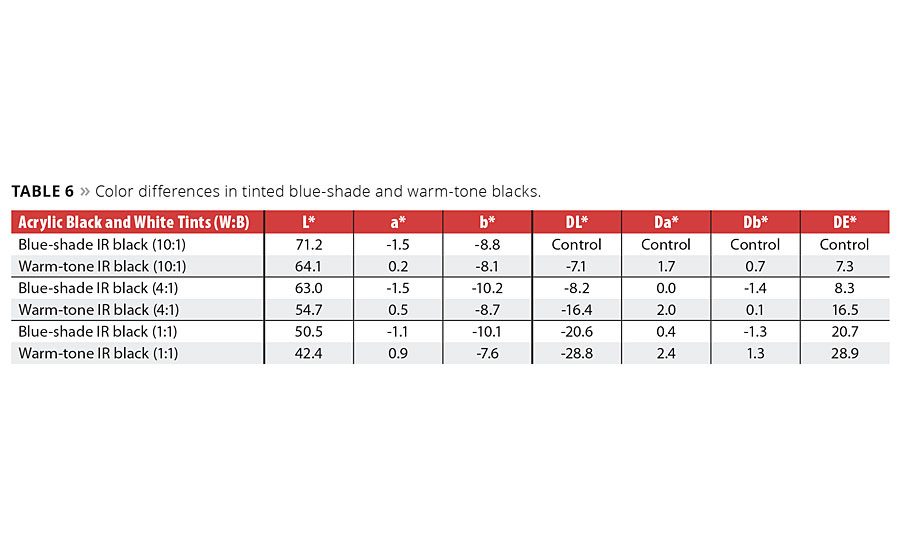

The larger difference in color can be seen in the tint color numbers. When let down at the same white:black ratio, the warm-tone black has a much lower tint L* at the different let-down ratios (Table 6).

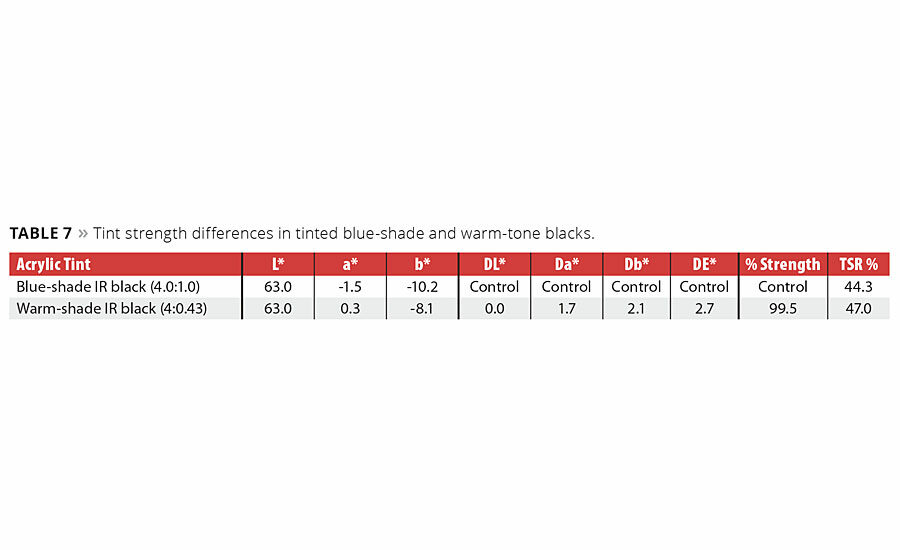

Instead of looking at a fixed let-down ratio, the relative tint strength difference between the pigments can be determined by holding the tint L* constant and determining the amount of black pigment needed to make this same L* value. The blue-shade IR black 4:1 (w:b) was picked as a standard and the warm-toned IR black was used to match that L* value. While it takes 1 full part of blue-shade IR black for the standard, it only took 0.43 parts of the warm-tone IR black to match the L* value. This shows that it takes less than half as much warm-tone black to make the same tint L* value as the blue-shade. This tint strength advantage is driven by the smaller particle size of the warm-tone IR black in comparison with the blue-shade IR black. The warm-tone IR black equal L* tint also has higher a* and b* values, giving a warmer tint that is often popular in building products. The warm-tone variant also has a slightly higher TSR in the equal L* tint (Table 7).

For highly durable coatings that need IR reflectance, the CICP PBr29 products are the high-durability workhorses. Depending on the application there is a variant that balances the properties of masstone color, TSR and tint strength. For masstone applications this variant of the blue-shade IR black is an exceptional example that maximizes the masstone color and TSR. It is in an easily dispersed form to attain those properties without grinding the pigment, which can drive the particle size down, reducing the jetness. Taking the pigment grinding step out reduces the possibility for contamination, which can reduce TSR. Easily dispersed pigments allow this IR technology to be quickly incorporated into new formulations in the lab and then be easily and quickly scaled up in production. For products that require mid-tone warm-shade tints common in building products, the warm-toned IR PBr29 gives performance and economic advantages.

IR-Optimized TiO2

While black pigmentation has seen changes from carbon black to IR blacks and optimization for specific applications, white pigments have also seen advances for IR optimization. While standard TiO2 (PW6) reflects visible light by engineering its particle size to scatter those visible wavelengths optimally, variants with a larger particle size have been developed to optimally scatter the longer-wavelength n-IR light.

The qualitative difference between these products can be seen in Figure 8. As before, the solid lines represent the white coating over the black portion of an opacity card and the dashed lines represents the reflectance over the white portion of the card. The thicker line represents the larger, IR-optimized TiO2. Both versions have good UV attenuation for durability. In the visible wavelengths both pigments reflect well, but there is a difference in the shape of the curves. Over white, the differences are masked by the white substrate underneath. Over the black portion the standard TiO2’s preference for scattering bluer wavelengths can be seen by the max reflectance just past 400 nm and diminishing from there. The IR-optimized TiO2 has a much flatter reflectance curve and overall less scattering in the visible part of the spectrum. An interesting side benefit of this scattering is that when examined in transmission, the blue-scattering standard TiO2 looks much yellower than the IR TiO2, which scatters visible light more neutrally. That means for applications that are lit behind, like signage, or applications like diffuse skylights or films that are used for shade, will appear more neutral in tone with the IR TiO2.

When the IR section of the curves is examined, the IR-optimized version has a higher reflectance than the standard white, especially when the over-black section is compared. This shows the advantage of the IR-optimized TiO2.

This difference in scattering areas can be seen when looking at the visual and TSR opacities at different P:B ratios. The standard TiO2 has higher visual opacity for any level of pigment loading. Considering that the TSR opacity looks at the complete spectrum, including visual opacity, the IR-optimized white has a higher TSR opacity at any pigment loading. The IR-optimized version is also gaining TSR opacity faster than the standard TiO2 (Table 8).

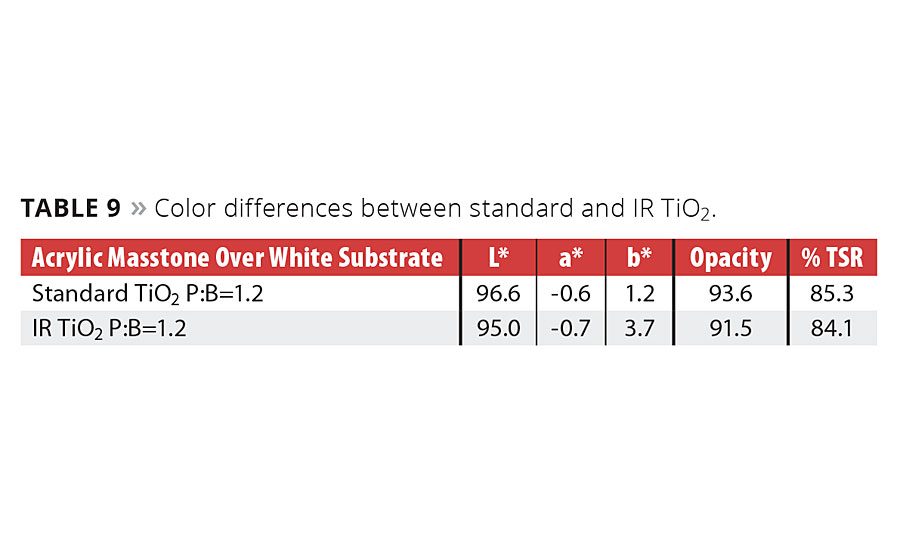

Besides the opacity differences there are color differences between the two TiO2 versions. The standard TiO2 has a higher L* due to its greater scattering in the visible. Because the standard TiO2 is specifically particle size engineered to give a cool toned white, it has a much lower b* value than the IR-optimized white, which is much more yellow in tone (Table 9).

While large gains can be made by swapping out standard blacks for IR blacks, the IR-optimized TiO2 can also boost performance relative to standard TiO2. There are a number of different sized TiO2 products to scatter specific wavelengths preferentially. While the CICP IR blacks are available in a ‘Black Rainbow’, the TiO2 variants are available in a ‘White Rainbow’ of options. There can also be gains made by using IR black pigments with the IR-optimized TiO2, especially when it comes to reducing the effect of a dark substrate on the TSR of a coating.

IR Blacks with TiO2 Options for Optimizing Properties

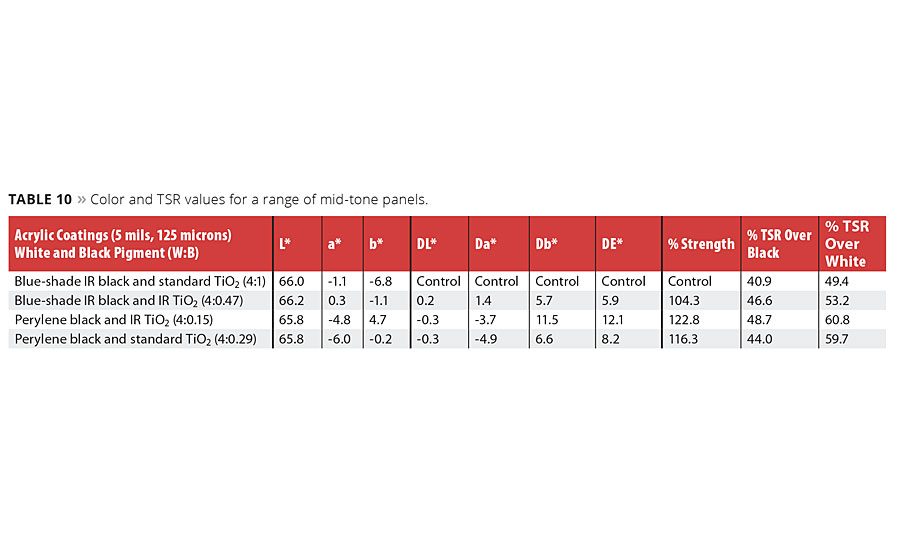

Table 10 shows the color and TSR for a range of mid-tone panels. The standard for the series is 4 parts standard TiO2 white with 1 part of the blue-shade IR black. The tint has excellent color tone with negative b* and a* absolute values. This shade, based on L*, was matched in a round-robin type test of the perylene black, standard TiO2 and IR-optimized TiO2. The amount of white pigment was held constant at a P:B=0.8 and the amount of black pigment varied.

The first match was made using the IR-optimized TiO2 with the blue-shade black. Perhaps the biggest difference to notice is that when holding the TiO2 constant, it only takes 0.47 parts of the blue-shade IR black to match the L* value of the standard. This can be explained by decreased scattering of the IR-optimized TiO2 in the visible. Because this IR TiO2 is scattering less in the visible than the standard TiO2, the IR black’s absorption lowers the L* value faster.

The next panel was made with the perylene black with the standard TiO2. Again holding the concentration of the white pigment constant, we can see that it takes only 0.29 parts of perylene to match the L* value made with 1 part of the blue-shade IR black. Since the TiO2 is the same, this panel shows the difference between PBk32 and the PBr29 coloristicly. That means that from a strength basis (on equal L* value), the PBk32 is about 3.5 times stronger than PBr29.

The last panel was made by matching the L* of the standard TiO2 and blue-shade IR black panel with the perylene black with the IR-optimized TiO2. The low loading of 0.15 parts, half of what it was with the standard white for the perylene black, points to its relatively high tint strength along with the relatively low visible scattering of the IR-optimized TiO2.

While all the tints are at the same L* value, there are differences in the a* and b* values. The standard PBr29 was bluest with the standard TiO2. The biggest shifts were in the b* values with all the other tints being less blue than the standard. The tints made with perylene are inherently greener than the tints made with the CICP IR black. The key is to know that switching from one combination of white and black to another will have inherent color shifts and changes in black to white pigmentation. The black pigments have different absorbing areas and tint strengths while the TiO2 whites, due to their different maximum scattering areas, have different ‘pasteling’ strengths and tinting tone.

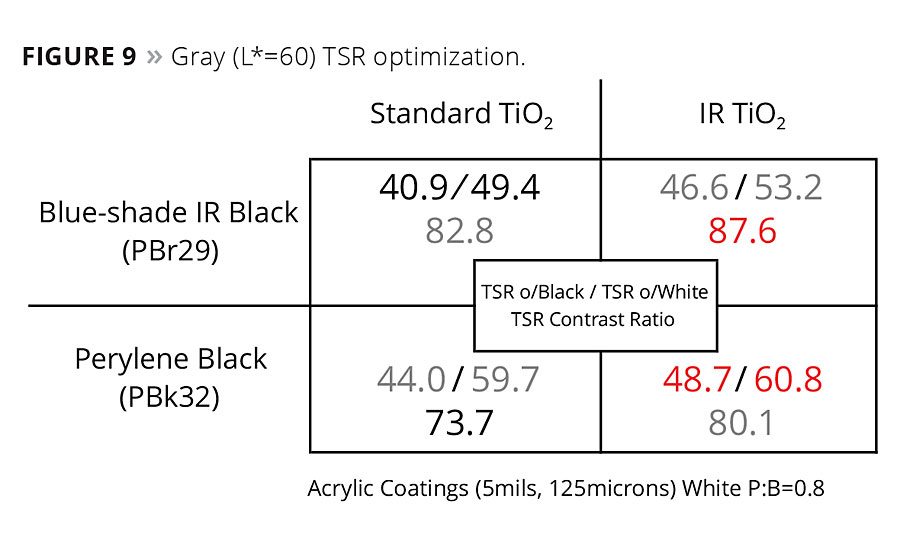

All of these panels were based on a P:B for the white at 0.8 for 5 mil (125 micron) films. It is interesting to look at the TSRs over white and black and the TSR opacities. Figure 9 gives some insights into how the pigments are working together and how to maximize the performance of a coating. In this table the max values for each of the three values (TSR over black, TSR over white and the TSR opacity) is in red, middle values are in gray and the minimum values are in black.

- The standard TiO2 and PBr29-based tint have the lowest TSRs over black and white.

- The PBr29 and IR TiO2 have the highest TSR contrast ratio.

- The perylene black and standard TiO2 have the lowest TSR contrast ratio.

- The perylene black with IR TiO2 have the highest TSRs over black and white.

The inherent pigment properties of scattering, absorption and transparency explain these differences and can be illustrative of what will happen when making more complex color blends.

The standard TiO2 and PBr29-based tint have the lowest TSRs over black and white because the PBr29 has n-IR scattering, but also some slight n-IR absorption. The standard TiO2 has less IR scattering than the IR TiO2, so it is the lowest overall TSR values. This would be the easiest to implement because it just requires the swapping of standard black for the IR black and the use of standard TiO2. It also has a neutral (though much weaker) tint most like a carbon black.

The PBr29 and IR TiO2 have the highest TSR contrast ratio because both the IR TiO2 and the PBr29 are contributing to scattering. PBr29 also has slight absorption in the n-IR, which contributes to the higher TSR contrast ratio. This combination would give the most consistent TSR based on variable substrate reflectance.

The perylene black and standard TiO2 have the lowest TSR contrast ratio because the PBk32 is n-IR transparent and not adding scattering or absorption to the pigment blend. The standard TiO2 has less n-IR scattering than the IR-optimized TiO2, so together they are the least n-IR blocking. This combination would be most susceptible to different substrates reflectance’s affecting final TSRs.

The perylene black with IR TiO2 have the highest TSRs over black and white because the IR-optimized TiO2 has the best n-IR scattering and the PBk32 is n-IR transparent. The blend of the two takes the shape of the reflectance curve in the n-IR of the IR TiO2, which is higher than the standard TiO2 and the PBr29, which is scattering, but also slightly absorbing in the IR. The main issue would be confirming weathering performance is adequate to meet requirements for this black:white tint.

These 12 values of TSR and TSR opacity based on the scattering, absorption and transparency of four different pigments embodies the effects that will dictate the performance of more complex color formulations.

Figure 10 shows the reflectance curves in the visible spectrum and a portion of the most relevant n-IR spectrum. Numerous areas are noted that support the previous statements.

Conclusion

IR pigments allow paint formulators and coatings chemists to develop differentiated and functional coatings. Foremost in this technology, the inorganic PBr29 variants give the best balance of TSR, durability and substrate independance. PBk32 and IR-optimized TiO2 can be used to produce optimized TSR performance but with potential weathering performance and cost restrictions respectively. The best solution for an application will depend on the specific TSR, color, cost and durability requirments. Special commercial variants of the PBr29 IR black chemistry are available in easily dispersed form that allows rapid incorporation into new formulas in the lab, along with easy scale-up in production, without the costly and variable pigment grinding step.

This study was a introduction to the basics of IR pigments. The specific scattering, absorption and properties of these pigments and their effects can be used to understand more complex pigment blends, the effect on TSR performance and ultimately how the technology can be applied to real-world applications. The variations in resin, formulation and manufacturing, along with application and intended final coating performance outside of TSR, like weathering, formability and other properties are beyond the scope of this article and should be verified when incorporating any new raw material.

Report Abusive Comment