In mid-2016 I retired after 45 years in the coatings industry. During this period, I held various technical and managerial positions at PPG Industries, The Sherwin-Williams Company, AkzoNobel, Bondo Corporation, and most recently, Covestro LLC. I have witnessed significant changes in the industry - from a pre-internet period in which large main-frame computers were installed to handle production, sales and accounting functions, to the current time of instantaneous communication and profound changes in the product development process via the rapid advances in computer hardware and software. In this article I will discuss what I consider to be major changes in the product development process - many of which have been enabled by the computer revolution.

A Faster and Higher-Quality Process

The amazing developments in computers and software have enabled the very rapid preparation of formulations of paint batches of any size for lab testing, pilot plant batches and production-scale batches. The product development timeframe, starting with experimental lab batches and proceeding to full-scale production of commercial paint batches, has been significantly reduced. This reduction in time has enabled marketing and sales functions to speed up their activities for new product introductions. The time reduction has also been realized in increased rates of inventory turnover and improvements in inventory control.

Lab-scale product development now involves the rapid preparation of statistically designed experiments, analysis of results and identification of key formulation variables to obtain targeted paint properties. These capabilities have drastically improved the quality of paint formulation development and testing. To illustrate, the reporting of experimental test results with error limits for the measured values is now routinely provided in statistical software packages (although not always reported in the coatings literature). The rapid sharing of experimental results with global teams is now routine, and around-the-clock product development - testing of experimental paints - can further reduce the time to market.

In the midst of all of these time reducers, the rate-limiting step has been preparation and testing of paints. Advances in automated paint preparation and testing with high-throughput screening methods are further advancing the industry’s capability for reduced product development time spans.

These improvements in paint product development are important for paint companies to remain competitive in a field in which a significant number of traditional paint formulators will retire in the coming years and many of their numbers will not be replaced.

New Business Opportunities

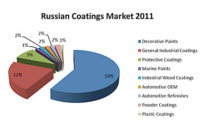

Another major advance is the shift in focus from customers to the markets in which customers are participating or may plan to participate (or exit) in the future. Raw material suppliers and paint manufacturers are evaluating new business opportunities in terms of overall “size of prize” potential; in such studies, paint formulation development, testing and commercialization often begin after intensive market studies are conducted. Data are obtained from market surveys, stock market reports, company reviews, intellectual property and personal interviews with prominent players along a particular market’s value chain. Today’s computerized access to such documents was unheard of in the coatings industry in this author’s not-too-distant past.

Today’s instant global communication tools have also enabled global product teams composed of technical, marketing, sales and production staff to rapidly assess such business opportunities. Thus, market opportunities are now being studied across entire value chains to ascertain whether to proceed with product development, field testing, scale-up for production and commercial introduction. This “new” approach has intensified the need to understand all parts of a value chain to identify key players, manufacturing, product distribution and delivery, existing and pending regulatory and compliance activities, and what can be offered by the paint manufacturer and raw material supplier. This discipline can identify potential customers, hurdles and business opportunities that an older, traditional emphasis on product development could not. These strategies, while not totally dependent on the computer and software tools now available, can be taught and implemented at extraordinarily rapid rates across global product development teams.

Evolving Challenges and Partnerships

In addition to the significant changes in paint product development and the justification for entering new or existing markets, paint manufacturers and their raw material suppliers are challenged by customers who may want game-changing products rather than incremental product improvements; today’s customers are demanding new products at faster rates than previously known in the paint industry.

One interesting development has been “for hire” product development groups, which include paint formulating expertise. These independent groups can provide turnkey services for highly focused projects. This approach is now receiving more intense scrutiny as an entire generation of coatings industry technical, marketing and sales personnel prepare for retirement.

The part that the customer can play in new product introductions is also evolving into true partnerships to enable rapid prototyping, market testing, small-scale manufacturing and field testing.

Although these developments are impressive, new developments such as 3D printing and carbon fiber composite surfaces will challenge future product development teams to improve current product development techniques to meet these challenges.

Report Abusive Comment