UV Protection

For both indoor and outdoor applications, light-induced damage on wood surfaces is reduced significantly when the harmful UV component of sunlight is filtered out by UV screeners. As is typical for indoor clearcoats, organic UV absorbers used in concentrations of 1-3% (calculated on binder), depending on coating thickness, considerably reduce yellowing. For exterior applications, clear varnishes and transparent pigmented stains generally require 1-5% UV absorber (UVA) or 1-3% UVA/HALS blends to obtain the desired long-lasting protection (percent on resin solids).Improved Photoprotection

Progress has been made in the development of new additives for wood protection. An experimental UVA based on a high extinction and red-shifted absorbance chromophore (shifted toward longer UV wavelengths) shows better wood color protection than currently used benzotriazole UVAs. On the HALS side, a developmental compound has been identified that provides excellent color stabilization of natural light-shade wood by a simple substrate pretreatment before application of a UVA-containing finish.This new HALS compound is a milestone in the development of durable color protection of natural wood substrates. It is the first additive that totally inhibits photo-oxidation of lignin and acts as an efficient color stabilizer by simple aqueous solution pretreatment of the substrate. However, durable protection against yellowing and photodegradation of wood surfaces is only achieved if the HALS is used in conjunction with a UVA. The latter is either applied in the pretreatment itself or preferably in a subsequently applied topcoat.

With the new photoprotection concept, previously unattained wood color stability and improved coating durability can be obtained. Typical indoor and exterior wood coating applications illustrate the benefits of using appropriate types and amounts of stabilizers in pretreatments and topcoats.

Photoprotection of Wood with UV Absorbers and UVA/HALS Blends

The first way to protect wood against yellowing and darkening is to prevent its sensitive components from absorbing UV radiation. The simplest way to achieve this is to use UVAs in clear finishes to cut off harmful UV radiation before it reaches the substrate. In contrast to fillers and micronized pigments, which to some extent mask the natural character of the wood when used at the levels required to be effective, organic UVAs do not reduce coating transparency or affect the visibility of wood grain and texture. HALS are used in topcoats to reinforce binder resistance to photo-oxidation. Figure 1 shows the structures of some commercial UVA and HALS products.

Figure 2 shows the absorbance spectra of various types of organic screeners. As shown by the spectral shift vs. the benzophenone type Chimassorb 81, the benzotriazole type Tinuvin 99 and UVA-3 are the best adapted to ensure efficient protection of wood surfaces as a result of their broader absorbance range. The experimental CGL 210 MPA, based on a new chromophore, has been designed to provide even stronger absorbance than Tinuvin 99 and UVA-3, especially in the UV-A (320-400 nm) range.

Assessment of Wood Degradation and Color Variation

Sample and Substrate Preparation

To avoid the influence of substrate variations and to correctly assess additive performance, the pretreatments and topcoats are applied on adjacent sections of single boards or panels. The standard coating method consists of one application of aqueous pretreatment followed by two layers of topcoat. Total film thickness depends on substrate porosity, coating type and end use.Exposure Conditions

Accelerated weathering tests are performed with a QUV device equipped with spray nozzles and A-340 fluorescent light tubes. Exposure cycle: 5 hours' UV light at 60degC (black panel) and 1 hour spray at room temperature. UV light exposure tests are performed with A-340 tubes in dry conditions or with filtered Xenon light sources.Color Variation Measurement and Degradation Assessment

A MacBeth Color-Eye 1500 Plus spectrophotometer is used for color change measurements. For each coating section the results are reported as the DE change resulting from UV light exposure. Coating degradation is monitored by changes in gloss and by simple visual assessment of cracking and flaking.

Wood Photoprotection with UVAs and UVA/HALS in Topcoats

Figure 3 shows a typical example of wood color protection with UVA in an indoor maple furniture application. The results are summarized as the DE change between exposed and initial color levels of each sample. The DE variations indicate a general strong increase resulting from the modification of the three components of DE, lightness L*, reddening a* and yellowing b*. The changes induced by panel ageing are usually a strong decrease in the lightness L* (darkening) and an increase of reddening a* and especially of yellowing b*.The color change of the maple wood substrates coated here with an alkyd/amino, resin-based, acid-cured furniture coating is shown as a function of exposure time up to 960 hours in Xenotest 150 equipment.

The DE increase is quite rapid in the first 240 hours (up to half of the final color increment) and levels out later. The use of UVAs considerably reduces the speed of initial yellowing and limits its final extent. At a concentration of 2% Tinuvin 99 on dry resin content, the final DE change is reduced to one third of the value of the non-UV-protected coating.

Figure 4 shows the results of an evaluation of three different UVAs without HALS, in an outdoor-grade, long-oil, alkyd varnish on pine. After 3,600 hours' accelerated QUV exposure (with spray cycle), some areas show total degradation of both the coating and the wood surface, while others vary in condition from poor to excellent. Performance of all three UVAs evaluated clearly depends on UVA concentration. Good protection is obtained with 1% CGL 210 MPA and 2% Tinuvin 99 but requires at least 4-5% Chimassorb 81! With less than 4%, the protection provided by the benzophenone Chimassorb 81 is totally insufficient. The experimental red-shifted absorber CGL 210 MPA performs well and is as effective as the standard Tinuvin 99 at only half the concentration. Outdoor exposure tests with this system are in progress. After nearly 18 months' exposure, all topcoat sections are still in good condition; the only difference being the wood substrate color, the non-stabilized sections and those treated with lower concentrations of Chimassorb 81 showing stronger darkening.

Improved Photoprotection Results

Attempts to stabilize lignin with commercial HALS failed to provide significant improvement of wood color retention. A series of experimental additives has been tested in the hope of obtaining better protection. A new derivative, CGL 1198, gave fairly good results on several types of wood. The best performance was obtained by using this new additive in a wood-impregnating primer treatment subsequently topcoated with an UVA-containing finish. The treatment with the primer has limitations as far as stability and wood type. However, the protective effect is durable when a UVA is used to filter out the UV light either by external effect (UVA used above the primer in a top varnish) or by internal effect (UVA used in combination with the new additive in the primer itself). In the latter case, durability of the protective effect seems to depend on coating thickness or UV opacity.

Example of a Long-Oil, Alkyd Varnish on Pine (Indoor Furniture Application)

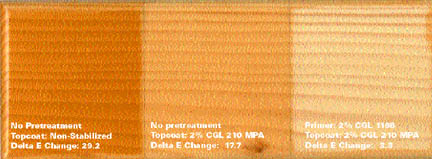

Figures 6 and 7 show the color variation of the differently stabilized coating sections following up to 1,500 hours of exposure under a dry UV A-340 light source. A very rapid initial yellowing (DE variation of 20 units after only 200 hours), essentially reflecting the modification of the wooden substrate, is observed when the coating is totally non-stabilized. With 2% CGL 210 MPA on binder solids in the topcoat and no pretreatment, a marked decrease in the discoloration rate occurs during the initial exposure period as well as a significant reduction in the final level of yellowing. The panel color can be almost completely maintained by combining a 2% CGL 1198 aqueous substrate pretreatment with the CGL 210 MPA stabilized topcoat. The new HALS stabilizer is clearly the greatest contributing element to overall long-term color protection of the substrate.

Example of a Waterborne Acrylic

Dispersion Coating on Pine (Exterior Application)

The coating system shown in Figure 8 consists of one primer layer of dilute acrylic dispersion with Tinuvin 292 or CGL 1198, followed by two layers of non-diluted dispersion as topcoat. After 2,400 hours' QUV exposure, the non-stabilized system shown in section 0 is fully degraded. With 3% Tinuvin 99/Tinuvin 292 on binder solids in the topcoat sections 1-5, the coating remains in excellent condition. The differences in substrate color between the sections are due to the effect of the type and concentration of HALS used in the primer treatment. CGL 1198 gives the substrate the highest color stability, in contrast to the very slight effect of the Tinuvin 292.Conclusion

Light stabilizers provide an effective solution to wood color protection problems and increase durability of wood coatings. In indoor applications, the effect of UVAs on substrate color protection increases with the shift of their absorbance characteristics toward the longer wavelengths (red-shift absorbance). An experimental UVA designed to meet these requirements shows superior performance to that of standard products. In addition, an experimental HALS derivative has been developed that provides a significant improvement in color stabilization of wood when used in impregnating treatments subsequently topcoated with the UVA-containing finishes. The two experimental additives show interesting protection results on various natural light shade wood species.For exterior applications, the combined effect of combinations of standard UVAs and HALS can be seen in a solventborne, alkyd clear varnish. The blends clearly provide the coating and the substrate with better protection than the UVA on its own. The new red-shifted UVA used in conjunction with conventional HALS in topcoats, and the new HALS derivative in primers are expected to provide further significant performance improvements, particularly in clear and slightly pigmented systems. Accelerated weathering exposure tests with the new concept show promising results. Outdoor exposure tests with both solvent- and waterborne systems are in progress.

For more information on color stabilization, contact Daniel Rogez, Ciba Specialty Chemicals Inc., Coating Effects, Klybeckstrasse 141, Business Line Coatings, CH-4002 Basel, Switzerland; phone +41 61 636 23 65; fax +41 61 636 27 30; e-mail daniel.rogez@cibasc.com; or Circle Number 63.

Bibliography

H.Derbyshire and R.Miller. Holz Rohw.Werkst. 39, 341 (1981).S.Grelier, A.Castellan and P.Kamden. Wood and Fiber Science, 32(2), 196 (2000).

D.Rogez. Light Stabilizers for Coatings, Eurocoat Conference, Nice (1991).

A.Valet. Light Stabilizers for Paints, Vincentz Editor, Hannover (1997).

Report Abusive Comment