Industrial water-reducible (WR) coatings based on WR alkyds, acrylics and polyesters are typically supplied at 25-35% volume solids. Consequently, they are often applied at high wet film thickness. The rheology (viscosity as a function of applied shear) of these systems determines many properties of the paint. These properties include anti-settling of pigments, color stability, application performance (including sag), and flow and leveling. WR coatings, unlike water-based latex systems, are true solutions of resins and rheological modifiers, and are more like those used in solventborne systems.

It is important to note the three main viscosity profiles used to describe the rheological behavior of resins in solutions: pseudoplastic (shear thinning), dilatant (shear thickening) and Newtonian (shear has no effect on viscosity). Pseudoplasticity is often referred to as thixotropy. However, while the two systems undergo shear thinning, pseudoplastic systems recover quickly after the shear is removed, while thixotropic systems take longer to build viscosity back up and do not recover the same level of viscosity. Because each profile has its own advantages and disadvantages, combinations of rheological additives are used to optimize final paint performance.

Commonly encountered rheological additives in WR systems include organoclays, castor oil derivatives, fumed silicas and WR cellulose esters. Below are some of the unique properties and benefits of each type of modifier.

Organoclays

These high-thickening, thixotropic modifiers provide good sag control and anti-settling properties. They require shear in water to activate. Organoclays' thickening properties are based on hydrogen bonding of the polar hydroxyl groups. Organoclays can reduce gloss and are not typically used in clear coats.

Castor Oil Derivatives

Often used with organoclays to prevent pigment settling, castor oil derivatives also require shear to activate. They do not thicken as well as the organoclays, and exhibit poor sag control, and flow and leveling.Fumed Silicas

More pseudoplastic than the previous two rheological additives, fumed silicas also provide high thickening properties due to the hydrogen bonding between the silicon dioxides (more than organoclays) and have minimal effect on gloss. Like organoclays, fumed silicas require shear to incorporate. However, they are also more expensive than organoclays.

Water-Reducible Cellulose Esters

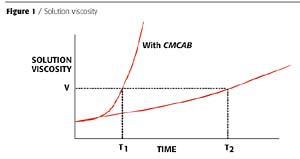

Carboxymethyl cellulose acetate butyrate, or CMCAB Cellulose Ester, is Newtonian in nature. Supplied as a white powder, it requires dissolution in a blend of water and ethylene glycol mono-butyl ether (other solvents can be used), and neutralization with an amine. CMCAB can be post-added to provide desired viscosity, and used in combination with other modifiers for optimal paint performance. These esters provide excellent flow and leveling. In addition, they build viscosity exponentially as water evaporates (Figure 1). Their high Tg (135 ºC) provides reduced dry-to-touch times.The choice of rheological modifiers is critical to the performance of any coating. WR coatings for many OEM applications, such as agricultural implements, under-the-hood automotive parts and metal shelving are applied in a wide variety of ways. They are often applied at high wet film thickness, with each method of application requiring unique rheological behaviors. Using a combination of pseudoplastic and Newtonian modifiers can provide properties that pseudoplastic modifiers alone cannot attain. c

Jos De Wit has been with Eastman Chemical Company for more than 15 years, working in manufacturing and R&D in chemicals, fibers and plastics. He is currently a Research Associate in coatings with emphasis on cellulose esters.

References

1 Cabot Corporation, Cab-O-Sil Division. Publication TD-102, 1994.2 Rheox, Division of Elementis Chemicals. Publication PB113 1998.

3 Lubrizol Corporation. Publication Irco8.doc, 1996.

4 Eastman Chemical Company. Publication E 325, 2004.

5 TAFE Educational Books, Surface Coatings, Vol 1 Raw Materials And Their Usage, New South Wales University Press, Kensington, Australia, 1983.

Report Abusive Comment