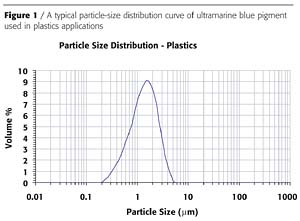

Ultramarine blue (CI pigment blue 29) is an inorganic pigment, (sulphurized silicic acid aluminum sodium salt) with the following chemical formula Na8-10 (Al6 Si6) O24 S2-4. China clay, sulphur and sodium carbonate are combined to produce a brick, which is kiln fired over three weeks at temperatures up to 850_C. The bricks are then crushed and milled to make the distinctive blue powder.

Particularly in food-contact applications, ultramarine's favorable toxicity profile is a major advantage. The pigment is heavy-metal free, lightfast, easily dispersed, non-migratory and insoluble in all solvents. It is very heat resistant too and well-suited to heat-cured applications. In addition, ultramarine blue has a bright, clean color that is ideal for color-correction roles.

Artizan AF

Because of the high demands of today's printing industry, we have developed a brand new range of ultramarine dispersions, called Artizan AF, aimed directly at the flexographic ink market. These products not only offer all the advantages of ultramarine blue but also take the hard work out of formulating. They are readily compatible with most waterborne resin systems and require no further grinding or dispersing.

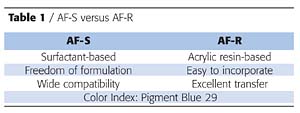

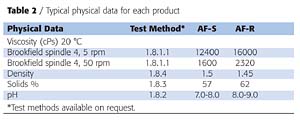

The range consists of two new products - Artizan AF-S and Artizan AF-R, which are surfactant- and resin-based colorants respectively. Artizan AF-S and AF-R are aqueous dispersions with a pigment loading of approximately 60%.

Unique Colour

The unique colour of Holliday Pigments' ultramarine blue enables users to produce strong, bright, red-shade blue inks. In addition to the obvious aesthetic qualities, the Artizan range also offers low-level security possibilities. Figure 3 shows the unique color space occupied by ultramarine blue.

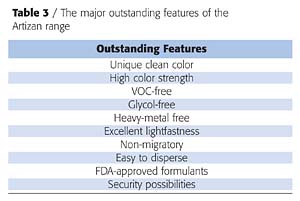

The unique red shade of the Artizan can also be exploited in blends with reduced dioxazine violet to help reduce costs and to replace the copper phthalocyanine in reflex blue-type shades, while still maintaining excellent resistance properties. Table 3 highlights the major outstanding features of the Artizan range.

Applications

Artizan AF-S and AF-R have been specifically developed for the environmentally conscious flexographic ink producer. The products work particularly well on brown kraft paper and packaging substrates. Unlike commercial organic blue pigments, the Artizan colorants retain their unique cleanliness of color, making them ideal for blending and tinting.

To maximize the unique color of ultramarine blue, a pigment loading level of approximately 40% is required in the final ink, which is comparable to other inorganic pigments such as titanium dioxide and iron oxide. Typical starting-point formulations are shown in Table 4.

Environmental Aspects

Legislation and regulations covering safety, health and the environment are becoming increasingly stringent. The most relevant pieces of legislation relating to the ink market are the restriction on VOC emissions and the restrictions on heavy metals content of colored or printed packaging (CONEG regulations and European Directive 94/62/EC 1994). Most ink makers demand that colorants should meet these purity requirements. This is one of the main reasons for the surge in market demand for aqueous flexo printed paper and packaging materials.The Artizan products have been carefully developed to be extremely friendly to the environment. They are both VOC- and glycol-free. Our production process is completely free from the use of heavy metals. Consequently, the Artizan range easily surpasses the strict heavy metal limits set in the CONEG regulations. All of these factors combine to make Artizan AF the preferred blue color of choice for all environmentally conscious ink producers and flexographic printers.

For more information on Ultramarine Blue and Artizan, contact Joanna Houldridge at Holliday Pigments Ltd, Morley Street, Kingston upon Hull, HU8 8DN, England; phone +44 (0)1482 388751; Fax +44 (0)1482 223114; e-mail infohp@holliday-pigments.com, or visit www.holliday-pigments.com.

Report Abusive Comment