One of the main deteriorating factors of mobile phones is water sticking to the surface of the Electret Condenser Microphone (ECM), a vital part of the phone. When this problem is solved, the durability of mobile phones will be greatly improved. This current study applied the water-repellent coating to the ECM of a mobile phone.

Material Preparation

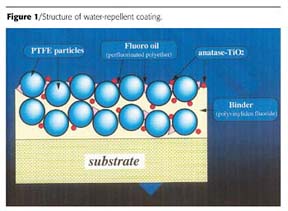

The coating is composed of low-molecular-weight polytetrafluoroethylene (PTFE) particles and anatase-type TiO2 nano particles, fluoro-oil(perfluorinated polyether) and binder (polyvinyliden fluoride), as shown in Figure 1.

The presence of the PTFE particles in the coating material makes it possible to improve the water-repellent properties so that it has a water contact angle of more than 150°. The inclusion of anatase-type TiO2 particles inhibits surface contamination by the photocatalytic reaction of anatase-type TiO2. The fluoro-oil contributes toward the water repellency of this material, which is being used to coat the surface of communication antennas in snowy regions.

Water-Repellent Property

The contact angle of 165° is obtained by dispersing PTFE particles in the binder (Figure 1). High water repellency is attributed to both the surface roughness formed by the PTFE particles on the surface of the coating and the existence of air under the water droplets on the surface of the coating.

As the concentration of PTFE increases, higher contact angles are obtained, as shown in Figure 2.

Mobile Phone Microphone Application

The performance of the ECM is easily deteriorated by the existence of water on the condenser surface. Therefore, water repellency of the electret condenser makes it possible to attain the durable mobile phone microphone.

Mobile phone microphones also face the demand of being small in size. Electret condenser microphones are required to be thinner and smaller in diameter for higher-density mobile phone fabrication. This forces development of a microphone robust from electrostatic induction noise and having better water-resistant properties. A multi-functional filter on the front surface of the microphone has been expected to meet these requirements.

ECM Basic Structure

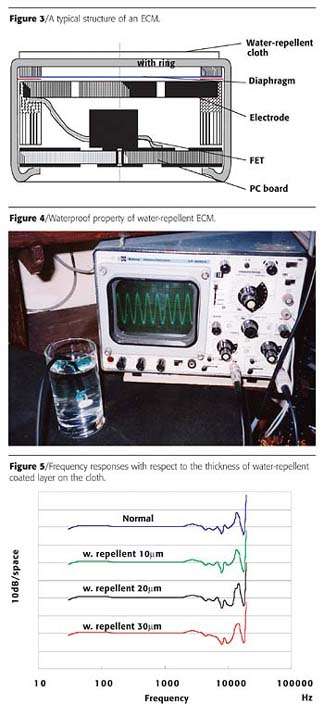

A typical structure of an ECM is shown in Figure 3. The ECM usually has a capillary slit to equalize the inner air pressure to the atmosphere. This is usually achieved by making a thin groove on the diaphragm ring. This groove leads outside water into the inside through a front filter and acoustic hole. Consequently, water damages the electret. The water-repellent coated cloth above the diaphragm of the electret condenser microphone prevents the invasion of water through the groove.Acoustic Characteristics

The waterproof property of the water-repellent electret condenser microphone is confirmed by immersing the microphone in water and detecting electric signals, as shown in Figure 4. The thickness of the water-repellent coated layer on the cloth above the ECM does not affect the acoustic characteristics, as shown in Figure 5.Conclusion

A water-repellent coating containing nano-sized TiO2 particles has been developed. The inclusion of TiO2 particles inhibits surface contamination due to the photocatalytic reaction of TiO2. This coating is being applied to mobile phone microphones. The water repellency of the electret condenser microphone surface has realized a practical solution for mobile phone durability without deteriorating the acoustic characteristics.References

1. Young, T. Philos. Trans Roy. Soc. 1805, London 95 65.2. Wenzel, R.N. Ind. Eng. Chem. 1936, 28 988.

3 Brand name: HIREC, NTT Advanced Technologies.

This paper was presented at the Nano and Hybrid Coatings conference sponsored by The Paint Research Association, January 2005, Manchester, UK. Conference proceedings are obtainable by contacting Janet Saraty, conference administrator, at j.saraty@pra.org.uk.

Report Abusive Comment