As much of the research and development work with glass flake, and hence understanding, has been carried out with coatings, it is through these materials that we can introduce most of the facets of incorporating glass flakes into product.

Apart from coatings for small-component parts, most coatings are based on organic resins. However, all organic coatings will, to some extent or another, convey moisture vapour and allow gas diffusion; preventing or resisting this is desirable and it is in this area that glass flakes initially found their niche.

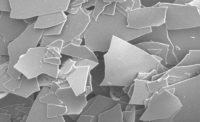

Particles of a high aspect ratio e.g., low thickness to surface area, as for example with platelets or flakes, can overlap each other and extend the path length for diffusion in a film, presenting a barrier to the passage of moisture and gas diffusion by creating a tortuous path through it. Particles of a granular or spherical nature do not overlap and offer only limited resistance to diffusion through the film.

High aspect ratio fillers are, therefore, termed barrier fillers and are desirable not just as fillers or extenders but for performance improvement in other areas also. These improvements can extend not only into the areas of diffusion resistance and mechanical reinforcement but also other areas such as fire retardancy.

The benefits of using plate-like barrier fillers, such as mica and micaceous iron oxide in anti-corrosive coatings in order to reduce moisture vapour transmission (MVT) have been known for a number of years. Other barrier fillers with varying attributes such as aluminium and zinc flakes have also been used as combination anodic and barrier fillers with varying degrees of success but may be problematical due to oxidation of the metal.

Glass flakes, introduced into coatings around 1960, gradually gained popularity for several reasons. Glass flakes have a large aspect ratio and they do not oxidize or corrode in the normal sense. They are totally impervious to moisture vapour and, being a synthetic material, they are consistent in composition and colour, and unlike mica they are not stepped. Other barrier pigments commonly used are opaque and often strongly coloured. Micaceous iron oxide in particular makes coatings and paints difficult to tint in light shades, while glass flake is clear. Not only that, glass flake manufactured from ‘C’ or ECR glass offers high levels of chemical resistance and is inert in most mixtures and environments. It has good mechanical properties and is generally considered non-hazardous or a simple mechanical dust hazard, particularly when compared with thin fibres and some other fillers.

Early glass flakes and the coatings they were used in were somewhat crude. The flakes were quite variable in thickness and plate size; the coatings were simple trowel or brush-applied materials basically designed as a glass fibre composite layer but with glass flake substituting for fibres. It was the mid seventies before good spray-applied glass flake coatings were available and these were generally thought to be exotic, unstable, difficult to apply and expensive. They were produced predominantly with the polyester resins used previously for GRP hand lay-up or manufactured as a vinyl ester variant for improved chemical resistance. Epoxy formulations containing glass flake were not common, and until more recent times were few and far between.

From the early 80s glass flake coatings started to become more accepted, as their performance and the benefits of long life and hence low whole life-cycle cost became apparent. At the same time prices, compared with other coatings, dropped due to the larger scale production of raw materials. This led to greater acceptability of these coatings within the market place. It was during this period, that much research was carried out regarding the use of glass flake as a barrier pigment, and the types of coatings using it increased significantly. This work eventually spilled into other fields.

Unfortunately the effects of using different concentrations of flake, flake aspect ratios, particle size distribution, critical pigment volume concentration and the unusual effects on viscosity were rarely understood and little work was done in this area. There was also relatively poor understanding of how the glass bonded within the various resin matrices.

Glass Flake Qualities

With the advent of glass flake markets developing, particularly in the anti-corrosion coatings sector, many different glass flake qualities were developed to suit the differing application requirements. Qualities are available with varying thicknesses, particle size diameters and glass compositions giving flake of varying performance. It is important to understand the effect of flake thickness and glass composition on overall coating performance.Principally, there are two manufacturing techniques employed to produce glass flake. The first is the bubble method, which has been in use for over 40 years, albeit in various incarnations. The second is the spun method.

The bubble method is much more cost effective, allowing for high throughput production and normally produced from pre-melted glass marbles. The drawback to this method is the limitation on control of product parameters. In the earlier years, flake produced using this technique typically displayed a product thickness variation of 1-18 µm and a high degree of fines, which are small particles/splinters of glass resulting from fracture of the glass during production and milling. In recent times the process has been developed to produce product typically with a variance of 2-9 µm. It is generally accepted that it is difficult to improve further on this process economically. Additionally, the technique can result in curved flake, the degree of which depends on the bubble size.

The spun glass method has the advantage of tighter product control, typically with thickness deviation at +/-1 micron for a given product, and no curved flake is generated. The drawback of this method is cost; it is typically 30% higher. The spun process is able to produce glass flake of a magnitude thinner than the bubble method. Thicknesses as low as 100 nm with a typical deviation of +/-25 nm are achievable at commercial level, with the lower limit in trials being 30-50 nm.

Consideration should also be given to glass composition. There are many different types of glass available; for the purpose of anti-corrosion coatings a chemically resistant glass (‘C’ glass) should be employed. Most glass flakes are produced from either Electric glass or ‘C’ type glass. Within the category of ‘C’ type glass there are many variations, with differing degrees of hydrolytic stability. Of the various types, ‘ECR’ glass, which is a modified C glass, is considered one of the more stable.

As with thickness control improvements, the cost of more chemically resistant glass compositions is higher. This is because these types of glasses have been produced from raw materials rather than pre-melted marbles, and also because those compounds impart extra chemical resistance.

Basic Parameters

It is important to understand that although the glass flake is impervious to moisture vapour and gas diffusion it does not present a continuous barrier in a resin matrix. The resin carrier therefore plays a very important role too, i.e., glass flake cannot make a poor resin film into an excellent coating, although it may substantially improve it. On the other hand, even excellent resins can benefit from flake addition. Additionally, glass flake offers differing aspects of mechanical reinforcement and fire resistance than those attained by adding fibre.Today many different types of coating resins are used with glass flakes, including, but not limited to, polyesters, epoxies, chlor-rubbers, alkyds, coal tars, vinyls and water-based acrylics. Although flake addition will generally improve the MVT resistance of almost any organic coating film or membrane there may be other benefits with new properties being imparted or existing ones improved. However, the level at which the glass flake should be added, the particle size distribution and ensuring adhesion to the carrier are of paramount importance.

Although glass flakes with aspect ratios as low as 10:1 will give benefit, generally the higher the aspect ratio the better the barrier presented. This premise has however to be tempered to some extent, as out of alignment large-aspect-ratio flakes can afford a direct path through the film where the film is less in thickness than the nominal diameter of the flake or cause stress raisers for crack propagation. In addition there are some properties that may be adversely affected when using large flakes such as flexibility and elongation to break. Also for consideration is the practicality of using large flakes e.g., when a coating has to be sprayed, the gun tip size is limited by several factors and the flake will have to be small enough to pass through the spray tip. It is therefore common that flakes with a nominal screen dimension across the flake (sdaf) of around 500 μm and below are used for spray application and flakes above this size i.e., as large as (sdaf) 1500 μm are rarely used except for hand applied materials. A further consideration with large flake is surface disruption and in consequence large flakes tend to produce rough surface finishes. There is also the possibility of blending flakes of differing size (sdaf) and not thickness, for instance incorporating a quantity of micronized (average diameter 30 µm) flakes with large flakes.

Flake size and thickness are only two of the issues involved in performance; the quantity of glass flake added and particle distribution are also critical. It is obvious that if thin glass flakes are used there are many more flakes than if thick ones are used for the same weight added and, therefore, the surface area to be wetted with the thin flake is vastly greater. This means that it may be possible to add up to 30% by weight of flake with a thickness distribution of 2-9 μm and not exceed the pigment volume concentration (CPVC) in the resin. It should be noted that the majority of flake quoted as Av. 5 +/-2 µm typically has a thickness distribution of 2-9 µm. If the same quantity by weight of a higher quality glass flake with a thickness Av. 2 µm and a distribution of 1-3 µm were added, then the surface area of this flake will be at least two and a half times that of the thicker one and there may be insufficient resin for surface wet out thus the CPVC level is exceeded. In any case the viscosity may be so high when changing from thick flake to thin flake that addition at the same level becomes impossible. This is one of the pitfalls in using glass flake. As with any formulation, minor modifications can render significant changes; this is especially so with glass flake compounding and it is necessary to carry out a full and often time consuming evaluation, though this often brings rewarding results.

Once a flake thickness has been chosen it is important to optimize particle size and addition level. That level will depend upon the type of resin being used, the other components such as surfactant, bubble release agent etc., and what other pigments or fillers are being used in conjunction.

A further consideration is whether or not coupling or bonding agents are used to provide better adhesion of the glass flake to the resin and the substrate.1 Adhesion plays a substantial role in the performance of organic materials in corrosion protection and the bonding of fillers into the resin is a very important facet in obtaining performance both from a corrosion resistance point of view and in mechanical performance. This is especially relevant for resins with poor wet-out characteristics, e.g., epoxies.

Silanes have been used for many years in the glass fibre industry to improve bonding and, therefore, performance. This improvement in performance is often seen both as an increase in some of the mechanical properties and a decrease in MVT rate. In thermoset resins it is possible to get substantial performance improvements simply by adding the chosen silane to the resin component, either just before or just after the glass flake is added. With thermoplastic materials however this is infeasible and the glass flake has to be pre-treated with silane. It is noticeable that pre-treated flake will often improve the bonding performance not only in thermoplastics but also in thermosets to a higher level than that achievable by adding the silane into the resin.

When silane is added to the resin, there is a critical level and the optimization curve is often very steep. This is true for each particular resin, glass thickness, particle distribution and addition level. It should also be noted that other fillers or additives such as thixotropic agents will affect the optimum level. Where silane is added by pre-treating the glass then the level of silane used is not as critical, provided that saturation of the flake causing agglomeration is not achieved. It is observed however, that with pre-treated glass a much higher level of glass flake can be added to the resin and in particular to the thermosets without exceeding the CPVC level. One down-side of using pre-treated flake is the cost and a change in safety hazard classification of the flake before addition to the resin.

It seems fairly obvious from the foregoing that barrier fillers with high aspect ratios and in particular glass flake, cannot simply be added at a nominal value, if good results are going to be obtained. Specifiers of coatings containing glass flake often state the minimum loading of glass flake2 and a thickness for the product to be applied at, but what knowledge do they base this information on? And what type of glass flake? A common pitfall is the use of low grade glass flake having been poorly formulated with the expectation that comparable service life, similar to that of a well formulated system on high specification glass flake, would be achieved.

Even if the characteristics of a particular resin and formulation are known, product formulation specification rather than performance specification can be dangerous. For example, a specification could state ‘Epoxy with a minimum glass flake loading of 30% by weight. This level of addition could in many formulations exceed the CPVC level and, while some coatings may perform well at this level of addition, other coatings would give better performance at lower glass flake loadings. In addition neither the flake thickness, nor particle size distribution, nor adhesion promoter, nor glass type is specified. It is therefore possible that a coating with very high performance could be precluded from being used under such a specification regime. It is more sensible if performance criteria rather than formulation criteria are specified.

With modern production methods glass flake can be produced at a consistent thickness, which may be varied for different purposes from around 10 μm thickness to as low as 250 nanometers and almost limitless particle size distributions are possible. Because the effects of thickness, particle size, addition level etc., were little understood, work was carried out to evaluate glass flake coating formulations, using flakes of differing thickness and diameter and with differing particle distributions. Some of the results were surprising, others expected and, because testing was carried out over a wide range of properties and not just diffusion and corrosion resistance, some interesting parameters were discovered. Of particular interest was the amount of fire resistance provided when using glass flake, the reduction in smoke emissions, improvements in polymerization shrinkage rates, heat distortion and creep. These results led to work being done with non-coating applications and engineering thermoplastics.

Experimental

Evaluation of various coating materials, thermoset resins and composites was undertaken. Tests involved: moisture vapour transmission (MVT); water absorption; Atlas cold wall (osmotic blister) testing; chemical resistance; cathodic disbondment; UV resistance; fire and flame spread characteristics; abrasion resistance; glass transition (Tg) (DSC) and heat distortion (DMTA); and a variety of other mechanical tests. Some of the test work and results are included, but for commercial reasons it is not possible to show the full set of test results.Flake Diameter and Performance

Tests were carried out to evaluate the mechanical performance of a glass flake-filled polyester coating system with a flake thickness at nominally 2.7 μm and two different nominal diameters, these being a D50 of 200 μm (Result 1) and a D50 of 575 μm (Result 2). The loading was 15% by weight in each case; results are in Table 1.

Although expected it is interesting to note the substantial reduction in shrinkage found when using the larger flake, the significant difference in compressive strength and elongation to break. These effects are caused simply by changing the aspect ratio of the flake.

Tests were carried out to evaluate the change in MVT afforded by varying the flake concentration. A pre-accelerated vinyl ester resin was used as the carrier resin with the only difference in the materials tested being the addition level of glass flake. Tests were conducted initially to zero-in on the area of criticality, then levels of 14%, 15% and 16% were used to carry out the main evaluation (Table 2).

As can be seen from these results the curve for addition quantity versus permeation is very steep with a 1% change in the addition level changing the permeation rate from 10.61 to 3.46. Further additions (not shown here) show a progressive worsening in MVT as the CPVC level is approached and subsequent additions show a rapid increase as CPVC is exceeded.

As expected the results show a similar pattern to that of the MVT tests, except that in this instance the 16% result is nearly as bad as the one at the 14% level, again showing how critical addition levels may be.

The steepness of the MVT performance curve is not always so high. In some instances the curve is a gradual slope at both ends with a flat bottom. This type of addition/performance curve is preferred as this allows not only some deviation for production tolerances but it also allows the formulator to look at other characteristics, for instance mechanical properties or fire retardancy, without compromising the other aspects.

In order to evaluate the addition level of bonding agent and the criticality, a standard vinyl ester glass flake formulation was used with the silane adhesion promoter level varied. Tests were then carried out to evaluate the performance of each cured sample.

As can be seen from Table 4, an addition of 0.6% silane improves coating performance considerably. It is interesting to note that although the bond strength is slightly better on the 0.95% level in all other respects the properties are very similar to those of the 0.2% addition level. Some of the test work showed initially worse results with silane addition compared with no addition until the level was further increased.

Particle Size Distribution

Evaluating change in performance by altering particle size distribution was examined. The test work was carried out by using micronized glass flake with a thickness of approximately 2.2 μm and a nominal diameter of 80 μm and a D50 of 50 μm in a resin formulation. This was compared with a formulation which contained the same quantity of flake but which had a different particle spread e.g., D50 of 35 μm.

Performance evaluation was carried out using an Atlas cold wall cell with tap water and a temperature gradient across the film of approximately 60 °C.

Test results showed that the formulation with the smaller glass flake (D50 = 35 μm) had worse performance than the existing coating. This was shown by the extent of osmotic blistering. Formulations were then produced with the glass being blended. A significant performance improvement was achieved when the glass was blended at a ratio of approximately 60/40 (60% of the D50 = 50 μm, 40% D50 = 35 μm). The test panel showed no osmotic blistering occurring where previously both panels showed blistering.

Evaluation of Thixotropic Properties

Differences in viscosity and thixotropic properties of a standard coating formulation using glass flake at a thickness of circa 5μm and 1.3 μm were evaluated. It had been apparent from previous test work that the thinner the glass flake the more surface reactive it appears. Flake of a thickness below 1 μm can be bonded together dry simply by using light compressive loads. When the glass flake is first manufactured there is no moisture on the surface and this is the point at which the silane-bonding agent is added to the glass flake if any is to be used.

As the glass ages over a few days moisture is adsorbed onto the surface and there is a slight weight gain coupled with a drop in reactivity. This moisture can only be driven off by using temperatures in excess of 340 °C but, on cooling, moisture will reattach over a period of a few days if left exposed to atmosphere. The moisture uptake will vary with surface area and the number of hydroxyl groups on the surface so this weight gain can be used to give some measure of surface reactivity. Evaluations show that the thinner glass flake has substantially greater reactivity than the thicker glass flake independent of surface area. Although not considered as a thixotropic agent, it was thought that there may be some synergistic effect capable of being used to benefit thixotropy e.g., in reducing the amount of fumed silica or other thixotrope within a coating film.

The glass flake level in the second formulation was reduced by 4% over that of the one containing 5 μm glass but has a surface area more than twice that of the original formulation. The thixotropic agent fumed silica was reduced by 50% for the second formulation, demonstrating the thixotropic properties of the thin flake and giving value to it.

Processing/Mixing Time

Glass Flake Coatings

It is evident from the above that there are substantial benefits in using glass flake, and this is particularly relevant to coatings. Glass flake coatings are often criticized in their flexibility. The addition of glass flake more often, although not always, increases rigidity and reduces elongation; however, careful choice of coating thickness may in many instances remove any associated problems. We used a flexural testing rig for testing a coated steel plate at 1 mm and 3 mm applied coating through tensile and compressive flexing modes. The rig was stopped and the plate spark tested on a fixed cycle basis. The coating applied at one millimeter, although showing surface stress cracks after 90,000 cycles, was spark free when tested at 15 kv right until the steel plate fractured at just under 140,000 cycles. The coating applied at 3 mm only completed one cycle before failure. The glass flake applied at 1 mm out performed five non-glass flake epoxies applied at between 350 μm and 1 mm one of which was stated to be a ‘High Build Flexible Epoxy’. There are many instances of polyester glass flake coatings in aggressive seawater duty being in service for more than 20 years and still showing no signs of degradation. More recently glass flake coatings have been developed with both polyester and epoxy resin bases that can be applied as single coats to structural steel work giving excellent edge coverage and obviating the necessity for stripe coating in many instances. This has been achieved by the use of glass flakes with differing particle size distributions changing the surface tension characteristics whilst allowing normal spray application.Conclusions

There are several properties that can be achieved and substantial benefits gained from using glass flake barrier fillers in coatings. First, however, the choice of flake to be used must be followed by ensuring that the formulation is specifically tailored for optimum performance. It is of no use to add arbitrary amounts of glass flake; the type and amount of bonding agent will vary not only with resin type but the surface area of the glass flake pigment and other components within the formulation.There are some negative aspects, and these relate primarily to impact resistance and stiffness, although not all materials are affected in this way. Glass flake coatings properly formulated not only give outstanding performance but also long life cycles. Many of the advantages in using glass flake, such as fire retardancy, mechanical properties and speed back to service have been ignored and yet there is still work to be done before all the benefits of glass flake fillers are understood.

For more information, visit www.glassflake.com or contact Composites One, 800/621.8003, www.compositesone.com.

Report Abusive Comment