Corrosion is the deterioration of metals and other materials resulting from oxidation, pollution and weather factors. Corroding metal parts or components greatly reduce service life, destroying millions of dollars in metal products each year. For this reason, corrosion-control methods are heavily investigated and researched.

There are different types of metal corrosion and also different solutions to the corrosion problem. One of the most effective methods of corrosion control is the use of protective coatings. The protection of metal structures and poles against corrosion can be met by using one-component polyurethane coatings. Binders for these coatings are often isocyanate prepolymers based on the reaction of a difunctional polyol with an aromatic or an aliphatic diisocyanate.

Difunctional Polyols

The Krasol® LBH series of products from Sartomer are difunctional polyols that can be used to make corrosion-resistant (environmentally resistant) coatings. These difunctional polymers are linear polybutadiene polymers with hydroxyl end groups, as shown in Figure 1.These Krasol LBH polyol products have a very narrow molecular weight distribution with polydispersity indices (Mw/Mn) of about 1.2 and functionalities close to 2. Due to a high concentration of olefinic double bonds and low molecular weight, these products are liquid at ambient temperature. The product is immiscible in water and alcohols; however, it is miscible in non-polar organic liquids, oils and bitumens. The Krasol series of products also offers excellent chemical resistance, good electrical characteristics, good low-temperature properties and hydrolysis resistance.

The polyol component is particularly useful in preparing polyurethanes in which it reacts through the terminal hydroxyl groups. In addition, it reacts through the double bonds along the polymer chain.

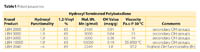

These polybutadiene resins are used as the basis for the manufacture of relatively low-viscosity prepolymers with good storage stability by reaction with toluene diisocyanate (TDI) or diphenylmethane diisocyanate (MDI). Properties of these polyols are presented in Table 1.

In addition to the Krasol LBH polyols, Sartomer also produces the prepolymers made from these polyols, designated as the Krasol LBD and Krasol NN series of products. The Krasol LBD series are isocyanate-terminated prepolymers prepared by the reaction of hydroxyl-terminated polybutadienes from the Krasol LBH materials and TDI.

The Krasol NN series are isocyanate-terminated prepolymers prepared from the Krasol LBH series of hydroxyl-terminated polybutadienes and a modified MDI.

Table 2 summarizes this and the properties of the primary commercial Krasol prepolymers.

Prepolymer Preparation

The isocyanate groups of both the Krasol LBD series and the Krasol NN series of products undergo all the reactions common to isocyanates, most notably the reactions used in polyurethane production. The prepolymer can be used in either one-component or two-component systems.

Applications

The Krasol NN products can be used as high-quality binders for the production of composite materials from ground rubber scrap, polyurethane foam and cork. Crosslinking of these one-component polyurethane binders by ambient moisture may occur at normal or elevated temperature. The mode of curing affects the final properties of the composite material. The processing characteristics can be adjusted by the addition of the catalyst. Depending on the nature and particulate size of the ground material, it is possible to obtain a large number of products for varied applications. The binder content is usually 7.5 - 20 weight percent, depending on the ground material and the application of the final product. Polybutadiene-derived urethane binders based on these prepolymers exhibit outstanding adhesion to the ground-cured rubber material and other nonpolar materials.Composite materials prepared using these binders have excellent physical and mechanical properties, good elasticity at low temperatures, and outstanding resistance to aqueous environments. However, they exhibit lower resistance to solvents, oils, gasoline and diesel oil. In contact with these materials the binder itself swells, but after evaporation of the liquid the composite regains its original properties. Because these polybutadiene prepolymer binders contain an aromatic diisocyanate, they tend to turn yellow and degrade when exposed to UV radiation. However, this degradation of the composite materials is only on the surface, and therefore does not affect the physical and mechanical properties and utility of the product. If necessary, the products from composite materials can be coated with protective layers or coatings. The product attributes are adhesion to non-polar materials, excellent electrical insulation properties, good low-temperature properties, hydrolysis resistance and very low moisture permeability.

Conclusions

One-component polyurethane coatings are used in a great variety of applications, such as for protection of steel structures and poles against corrosion. Binders for these coatings are isocyanate prepolymers based on the reaction of a polyol with an aromatic or an aliphatic diisocyanate. These polyurethane/polyurea coatings exhibit very good resistance to water and aqueous solutions of acids, bases and salts. However, materials prepared from the prepolymer based on MDI exhibit a low resistance to UV radiation. Therefore, these prepolymers are predominantly recommended for base anticorrosion coatings.Resistance to water and aqueous solutions of acids, bases and salts is an attribute of this new Krasol series of products. In addition, these products offer good adhesion to non-polar materials, excellent electrical insulation properties, good low temperature properties, hydrolysis resistance and low moisture permeability. These attributes allow the formulator to produce corrosion-resistant coatings for a variety of metal substrates.

For more information, visit www.sartomer.com.

Report Abusive Comment