Though most materials undergo testing in their research and development cycle, surveys show that the main reason weathering tests are conducted is to meet specifications required by purchasers of material. This paper is intended to provide some technical depth to those who are primarily running routine test methods to satisfy requirements, with the belief that such knowledge will benefit routine users.

Radiant energy incident to the earth’s surface in direct and diffuse components can be categorized in different wavelength bands of ultraviolet (UV), visible and infrared (IR). Radiometric quantities, definitions and equations are presented. Climate plays a key role in degradation processes. Different climates will affect materials in varying ways. The two benchmarks for weathering studies include subtropical and desert climates. This paper will also discuss how several answers may be obtained and decisions made during a test or in the evaluation of its results.

Why Do You Test?

This question was asked in a survey several years ago to determine why companies test. Nearly two-thirds of those surveyed indicated that they test simply “because we have to.” This means that, in order to sell their material, they were required by their buyer to prove the performance of their material to outdoor conditions. Most of this testing is done to exacting corporate, industry or government specifications. Without data to support the performance of a new formulation or process the buyer simply would not agree to purchase their material. This demonstrates the importance of test standards and specifications and, by extension, the importance of understanding how to properly conduct them.Other responses to the survey included the need to compare materials to competitors, presumably to facilitate sales and marketing campaigns for a company. While almost all testing is in some way related to research and development, about 10% of the testing done was strictly for these purposes, while another 10% tested to ensure that their material would meet warranty claims, or other requirements.

Answers Expected From Weathering Tests

“How does my material compare?” Material ranking technique is commonly performed when comparing a new formulation to a “known” or control material. Understanding weathering test applications and evaluation techniques should enable one to accurately rank materials by performance, in terms of durability, cost, etc. ”Known materials” have been previously tested and characterized such that their performance is well understood and documented. These may include standard reference materials developed by an industry, such as polystyrene reference chips or blue wool materials, or may be an old formulation of a specific material developed internally by a specific organization.

For all accelerated testing, a primary concern is correlation, how well the laboratory test results compare to what occurs in the actual end-use environment of a material. Weathering testing may allow one to understand and identify a material’s likely failure mechanisms in service life. Understanding these processes may lead material scientists to develop new formulations and processes that inhibit these mechanisms. Optimizing formulations may be the primary factor in testing, however new surface preparation methods or cost-saving processes may also be evaluated during a weathering test. Achieving high correlation factors is paramount for accurate service life predictions, the ultimate goal of weathering tests. Correlation factors and acceleration factors must be determined empirically for each type of material.

Factors of Weathering

The three main factors of weather that cause degradation to materials are light energy (solar radiation), water and heat (temperature). It is not merely a matter of “how much” (quantitative aspect) of each of these is present and will ultimately cause degradation to materials, also important are the qualitative aspects such as different wavelengths of light, different phases of moisture, and actual temperature cycling. Water contact may occur in several forms or phases, each likely to contribute differently to the degradation processes. While the temperature of a material can significantly influence the rate of its degradation, temperature cycling can cause mechanical stress, which in turn may initiate more types of degradation than would extended durations of high temperatures, by itself, particularly in composite systems. The synergistic effects of temperature, moisture and radiation make the study and predictability of weathering tests extremely difficult.Light (Radiant Energy)

Terrestrial daylight is commonly regarded in three main wavelength bands. According to the CIE (Commission Internationale E’clairage) Publication 85, daylight nominally consists of wavelengths of energy between 295 and 3000 nanometers (1 x 10-9 meters). Wavelengths between 295 and 385 nm are considered the ultraviolet (UV) portion of the solar spectrum, comprising 4-6% of the total energy. The UV portion of the spectrum is commonly, further separated into the UV-A (between 315-385 nm), and the UV-B (between 280-315 nm) range. Ozone absorption in the stratosphere eliminates measurable radiant energy below 295 nm. Visible radiation (energy detectable by the human eye) is between 385 and 780 nm, making up approximately 45% of the solar spectrum. Nearly half of the energy from the sun is contained in the near-infrared (N-IR) portion of the solar spectrum beyond 780 nm.The cut-on wavelength of terrestrial sunlight and the percentages of each wavelength band will vary slightly depending on latitude, altitude and atmospheric conditions. Also, the defined break between the UV and visible portions of the spectrum varies depending on the source of the information. Some consider the UV portion of the spectrum to be between 295-400 nm. While this may be considered a trivial point, it must be understood when calculating radiant dosages for exposure, whether in outdoor or laboratory tests. The variance between the 295-385 range and 295-400 may be as much as 10%, which could be extremely important when attempting to predict service life estimation for a material.

Photon energy increases with decreasing wavelengths of solar radiation. These shorter wavelengths typically contain enough energy to break chemical bonds in the polymeric structure of a coating. As the chemical structures change, appearance and physical properties of a material will also change, resulting in the physical or chemical degradation known as weathering. Consequently the higher energies contained in the UV portion of a spectrum are the most important for discussions of material degradation. While photochemistry is a complex subject and beyond the scope of this paper, there are two important laws of which we must be mindful:

· A material may only be affected by the wavelengths of radiation it absorbs.

· Photochemical changes can only occur if the radiant energy absorbed is great enough to break (or alter) chemical bonds.

These concepts serve as the foundation for understanding the photochemical processes that occur as a material is being weathered, and more importantly, how to protect materials from these processes.

Direct and Diffuse Radiation

Direct radiation is that which reaches the earth’s surface without being scattered by any component of the atmosphere. For radiometric measurements, this is defined as radiant energy within a 6º solid angle field of view centered on the solar disc. Diffuse radiant energy is that which has been scattered by the atmosphere and, therefore, reaches exposed surfaces at all angles above a 180º plane. It can therefore be assumed that an exposed horizontal surface receives both direct and diffuse solar radiation. This is sometimes referred to as total, or global, solar radiation. It is common to expose specimens in natural conditions at some degree of tilt, angled towards the sun as a means to increase incident solar radiation, or to better simulate end-use conditions. In addition to radiation received from above, some radiation reflects off the earth’s surface (sometimes referred to as albedo radiation) and reaches the surface of a specimen. The amount of radiation reflected off the earth’s surface is dependent upon the ground covering. Bare rocks, sand or gravel will reflect much more radiant energy than a grass-covered surface. Water or snow will reflect an even greater amount of radiant energy.The ratio of diffused to direct radiant energy reaching the earth’s surface is strongly influenced by atmospheric conditions. Water vapor (humidity) and pollution will increase the amount of radiant energy found in the diffuse component. Therefore, the amount of direct radiant energy varies with climate. The desert location of central Arizona has a much higher percentage of radiant energy in the direct component, due to the significantly less moisture in the desert air than in a subtropical environment such as south Florida. A location with higher levels of pollution such as Los Angeles experiences dramatic reduction in the amount of direct radiant energy. Shorter wavelengths of energy are more likely to be scattered. Therefore, the percentage of UV in the direct component will always be less in total solar radiation.

The discussion of direct and diffuse radiant energy is important when considering exposure angles in a specific climate. Because of the high humidity in a subtropical climate such as south Florida, on clear days about 50% of the UV radiation is diffuse. Many days in Florida are not clear, which will result in an even greater percentage of radiation in the diffuse component. Consequently, in order to maximize incident solar radiation, specimens in a subtropical climate such as south Florida should be exposed at an angle close to horizontal, such as 5º. Conversely, a desert climate such as Arizona would have a greater percentage of UV radiant energy in the direct component (as much as 75%). The most radiant energy over the course of one calendar year would be received by specimens that were near the latitude angle of the exposure site – an orientation that would facilitate closer to normal incidence of the direct solar component.

Measurement of Solar Radiation

There are two main types of radiometers used to measure solar radiation. Those that measure total solar radiation (UV + Visible + IR) are called pyranometers. They measure radiation from a 180º solid angle field of view. The other type of radiometer is a TUVR, which stands for Total UltraViolet Radiometer, and as the name implies, measures the total amount of ultra violet. Because of the varying amounts of the direct and diffuse components of radiant energy at different exposure angles, it is necessary to measure solar radiation at angles that correspond to common angles of exposure.For an informed discussion of the measurement of radiant energy, it is necessary to first define some terms used in measuring and calculating radiant energy dosages received by specimens on exposure. Radiometers measure irradiance, the instantaneous levels of incident radiation. Irradiance is defined as the amount of radiant flux incident to defined surface area, and is commonly expressed in units of W/m². It is necessary to indicate the spectral range over which the irradiance measurements are taken or for which the values were calculated, such as 295-3000 nm (total solar) or 295-385 nm (total UV). Narrow-wavelength intervals of spectral irradiance measurements, usually cited in weathering standards and literature, are expressed in units of W/m²·nm.

More important for weathering tests is the concept of radiant exposure, expressed in J/m², and the time integral of (spectral) irradiance. Most radiant exposure dosages are measured in either kJ/m2 or MJ/m². Another unit of measurement, the langley, is seldom used, and by definition can only be applied to total solar radiation and not artificial light sources. A langley is equal to one gram-calorie per square centimeter. One langley is equal to 0.04184 MJ/m² (295-3000 nm). Again, by definition, a “langley of UV” does not exist.

Water (Moisture)

Depending on its phase, moisture will impact a coating on exposure differently. Moisture can take the form of humidity, dew, rain, snow, frost or hail, depending on the ambient temperature, and can have both physical and/or chemical effects on materials.Water absorption by synthetic materials and coatings from humidity and direct wetness is a diffusion-controlled process. This hydration of the surface layers produces a volume expansion that places mechanical stress on the dry subsurface layers. A subsequent drying-out period, desorption of water from the surface layers will lead to a volume contraction. The tendency of the hydrated inner layers to resist this contraction will lead to surface stress cracking. This oscillation between hydrated and dehydrated states may result in stress fractures. Depending on the diffusion rates in various organic materials, it may take weeks or months to reach moisture equilibrium.

The freeze-thaw cycle also causes another physical effect. Because water expands when it freezes, absorbed moisture in a material, especially in coated hardboard systems, causes expansion and stresses that lead to peeling, cracking and flaking in the coating. When a painted material starts to weather it develops a thin film of degraded material on its surface (chalking), which itself becomes protective of the subsurface layers. However, when rain washes away the chalked layer a “new” surface is exposed to the vagrancies of the weathering elements, thereby accelerating the degradation of the bulk coating material. Rain, which also periodically washes dirt and pollutants from the surface, has an effect upon the long-term rate of deterioration that is determined by its frequency. Cooling rainfall, especially after a period of sunlight, may cause a dramatic change in surface temperatures, which may cause further physical degradation to a material. Frozen rain, or hail, may also cause physical degradation to coatings because of the strong kinetic energy associated with its impact.

Moisture, in any of its forms, is important in weathering from several points of view. The chemical effects of moisture can be seen in the chalking of titanium dioxide (TiO2)-pigmented coatings and polymers. The structure of a polymer is photochemically altered, either with or without chemical participation of hydrogen or hydroxide ions, but the actual physical release of material on the surface is enhanced, if not caused by, the cyclic action of chemically absorbed moisture. Moisture may also act as a pH adjuster, especially when considering the effects of acid rain, which may cause etching of many coatings.

Temperature

The effect of solar radiation on a material is significantly influenced by the material’s temperature. The destructive effects of light are usually accelerated at elevated temperatures as a result of the increased rate of secondary reactions. Reaction rates approximately double with each 10 °C rise, though this may not be true of all materials or be seen when measuring physical or appearance changes. At high temperatures molecules have greater mobility. Reactions may take place at higher temperatures that occur at a very low rate or not at all at lower temperatures.In the presence of sunlight the surface temperature of an object is usually considerably higher than the temperature of the air. Solar absorptivity is closely related to color, varying from about 20% for white materials to 90% for black materials; thus, samples of different colors will reach different temperatures on exposure. Because the thermal conductivity and heat capacity of plastic substrates are generally low, much higher temperatures can be obtained on the coated surface than in the bulk of the material. The surface temperatures of the sample, a function of absorbed infrared radiation that varies with material color, and the ambient air temperature and their respective fluctuations during exposure, play a role in material degradation rates.

Diurnal and seasonal variations occur in solar radiation. Temperature cycling can cause mechanical stress, particularly in composite systems consisting of materials with disparate temperature coefficients of expansion. Temperature and its cycles are also closely linked with water in all of its forms. Decreasing temperature can cause water to condense on the material as dew, while a rise in temperature causes evaporation, and sudden rainfall can cause thermal stress. Finally, the combination of heat and absorbed solar radiation may cause constituents in a polymer (such as a plasticizer) to volatilize out of the system. An automobile’s instrument panel is one example of this. The vinyl skin covering an instrument panel must contain plasticizers that make the polymer pliable for fitting around the non-planar shapes of the panel. As a result of exposure, this additive may exude from the polymer and be deposited on the cover glass of the exposure box. In time, this volatilization process (loss of plasticizer) causes the vinyl skin to become brittle. Subsequent extreme temperature cycling may result in physical degradation such as cracking and deformation.

When considering the roles of light, moisture and temperature on the weathering of an exposed specimen, it is important to understand that these factors work together synergistically. For example, if a material is exposed only to one, or even two of these factors, it is very unlikely that the degradation incurred will look anything like that of a material exposed to outdoor conditions, where all three factors are present and play a role in the degradation processes.

Climate

In viewing a climatological map of the world, it is obvious that depending on latitude, weather patterns, topographical and geographical features, there are a wide range of climates. The World Meteorological Organization (WMO) has identified seven major climates around the world. The two most important climates (or benchmarks) for weathering tests are the subtropical environment, such as south Florida, and the desert environment, such as northern Mexico and the southwestern United States. Other climates, such as polar, tropical rain forests, humid meso thermal, humid micro thermal and undifferentiated highlands, are sometimes used as weathering test sites for specific applications. In most cases, the subtropical and desert environments are recognized around the world as the most severe climates for materials exposed outdoors in their expected end-use application.Secondary effects of weather, like gases and pollutants, cannot be overlooked as they may contribute to a material’s degradation. Gases and pollutants are key ingredients of acid rain, which may initiate entirely new reactions. In highly industrialized areas, where long-range transport of airborne acidic particles is a consideration, acid rain is the primary element driving the weathering process affecting a wide range of materials.

Dirt and dust may have non-interactive effects on the weathering process itself. These include the attenuation of ultraviolet radiation by ultraviolet-absorbing dirt, airborne grease, etc. which causes protection of the materials, and undesirable, semi-permanent ‘varnishes’ that may be photo-polymerized on the surface of exposed materials.

Mold, mildew and other microbiological and botanical agents may play a significant role in material degradation, particularly in tropical and subtropical climates, although they may not be generally thought of as weathering factors.

Acts of nature may not directly cause weathering processes to occur. However, acts of nature such as El Niño, La Niña and volcanism may affect climatic conditions, which in turn result in different degradation rates.

Why Test in These Benchmark Climates?

Exposures in the moist, subtropical climate of south Florida were first conducted in the 1920s and 1930s as the paint industry became increasingly concerned about the weathering resistance of their products, making this area an important historical outdoor testing region. The largest independent test sites are located in areas that are considered an inland location, and therefore do not see any adverse corrosive coastal effects. In the desert environment of Arizona, higher extreme temperatures are seen, which is known to cause higher stresses to automotive interior materials than any other climate of the world. Independent test sites are also located in areas outside of the Miami or Phoenix metropolitan areas to minimize industrial or urban pollution.Seasonal variability exists in both subtropical and desert environments. The amount of variation will depend on the exposure angle and climate, especially the atmospheric conditions that cause different ratios of direct and diffuse radiation. Because of the high percentage of direct radiant energy in a desert environment such as Arizona, there is a high seasonal variation for 5º exposures at that location. Exposures conducted at 5º in Florida are relatively constant in UV due to the scattering by water vapor. Exposures conducted at the latitude angles (which are 26º in south Florida and 34º in Arizona) result in minimized seasonal variations, because the sun is closer to the perpendicular of these surfaces over the entire year. A 45º exposure is optimal for Arizona due to the high direct beam component, and overall, Florida has less UV at 45º due to the diffusion of radiant energy.

Although higher amounts of UV radiant energy are received by exposed samples in Arizona, it should not be assumed that Arizona is a harsher climate for all materials. Due to significantly more atmospheric moisture, south Florida can be very effective in the degradation of coatings. Consequently, more coatings are tested in this environment than in the Arizona desert. However, the dry climate of Arizona, in conjunction with the extreme diurnal temperature cycling, has proven to be very effective in the degradation of interior automotive materials and many other polymers. For comprehensive evaluations, it is common for many companies to test their materials in both the subtropical and desert climates because the effects of these extremes will result in different types of degradation processes.

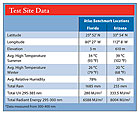

Weathering test sites are required to monitor and archive all major climatological data. A WMO-specified enclosure used to house the ambient temperature and relative humidity devices is required to have a double roof, essentially two pieces of wood over the top of the enclosure, with a small air space between. This is intended to inhibit any direct radiant energy from striking the roof of the enclosure. The enclosure must also be naturally aspirated to allow wind to flow through the housing. Also, the enclosure must be mounted at a specific height above the ground so that reflected solar radiation does not affect either the ambient temperature or relative humidity. Wind speed and wind direction sensors, relative humidity sensors, rain gauges, wet time sensors, and special radiometric devices are all connected to a data acquisition system for continuous monitoring of the significant weather parameters. (See Side Bars)

Reference black panel temperature devices are typically used to control temperatures inside laboratory weathering instruments. To facilitate correlation studies, for example, to temperatures obtained in outdoor exposures, black panel (and white panel) temperatures are also commonly measured. Because of the high solar absorptance of the black paint, these devices are used as a reference temperature that may be considered the highest temperatures experienced by specimens on exposure. The construction of the black panel and the quality of the coating applied to it are stipulated in standards like ASTM G151.

Report Abusive Comment