The coatings industry has responsibly moved in the direction of safer, environmentally benign consumer products with the development of reduced-VOC coatings and cost-efficient additives for use in decorative architectural coatings. In this article two examples are presented that illustrate the development and manufacture of industrial biocides for coatings that reduce negative impact on human health and the environment.

Two industrial biocides were successfully formulated with the minimal use of volatile organic solvents and dispersants in aqueous carriers. The fungicide, 3-iodo-2-propynyl butylcarbamate (IPBC), was formulated to minimize VOC as well as total cost of the finished product. Typical use-levels of about 1.0% in exterior applications and less than 0.5% in interior coatings prevent surface defacement, coating film deterioration and the proliferation of mold growth on moist interior coating films. Consumer exposure to VOC during and after paint application is reduced.

Similarly, BIT [(1,2-benzisothiazol-3(2H)-one)] was formulated as a dispersion in water at a fraction of the typical organic solvent concentration. The VOC was significantly reduced. Typical use-levels for the prevention of bacterial spoilage of water-based coatings are about 0.05%.

Both BIT and IPBC have short half-lives in the environment. During the manufacture of these products the quantity of volatile organic solvents processed is greatly reduced. Worker exposure is minimized. Specialized dispersion equipment significantly reduces cycle times.

Introduction

Over the past several years, there has been considerable discussion about green chemistry, green engineering and sustainability. These terms are often used interchangeably, and although there is a fair amount of overlap in these concepts, each has a quite distinct definition (Figure 1). Each seeks to address the issue of environmental stewardship from a slightly different perspective and, as such, each identifies a different set of issues and potential solutions.(1)According to Anastas and Warner,(2) Green Chemistry is “the design of chemical products and processes that are more environmentally benign and reduce negative impacts to human health and the environment.” The US EPA defines Green Engineering as the design, commercialization and use of processes and products, which are feasible and economical while minimizing (1) generation of pollution at the source and (2) risk to human health and the environment. Sustainable Development, or Sustainability, is generally defined according to the original definition of the Brundtland Commission,(3,4) that is, providing for human needs without compromising the ability of future generations to meet their needs.

In a recent publication,(5) the following 12 principles of green chemistry, green engineering and sustainability are presented: prevent waste; design safer chemicals and products; design less hazardous chemical syntheses; use renewable feedstocks; use catalysts, not stoichiometric reagents; avoid chemical derivatives; maximize atom economy; use safer solvents and reaction conditions; increase energy efficiency; design chemicals and products to degrade after use; analyze in real time to prevent pollution; and minimize the potential for accidents.

As each of the example products (water-based IPBC and water-based BIT) is discussed, the applicable principles will be highlighted.

Water-Based IPBC Formulation

Synthesis of the Active Ingredient, IPBCThe commercial chemical process is based on the following synthetic pathway: propargyl alcohol (liquid PA) and butyl isocyanate (liquid BIC) are reacted to form propargyl butyl carbamate (liquid PBC). PBC is reacted with iodine to form 3-iodo-2-propynyl butylcarbamate (IPBC). The IPBC is crystallized from aqueous methanol, filtered, washed free of impurities and dried.

The unique features of the ISP chemical process versus the conventional process are: (1) the utilization of an iodine-containing waste stream as a source of iodine and (2) the purification of IPBC by washing with water rather than organic solvents. These innovations eliminate an iodine-containing waste stream and the emission of volatile organic solvent vapors. In addition, the elimination of flammable organics in the purification stage yields a safer process.

Product Formulation

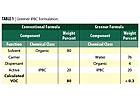

The use of organic solvents has been eliminated through the development of patented technology that facilitates the dispersion of IPBC in water. The formulation of stable 20% and higher percentages of IPBC in water has been successful. The calculated VOC content is nearly zero in the greener formulation; the conventional formulation is at about 80% volatile organics (Table 1).

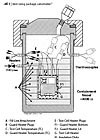

The dispersion of IPBC in water is performed in closed high-speed dispersion equipment to contain any atomized active. The vessel is vented to bag filters to contain any airborne particulates (Figure 2). Air permit requirements are specific to the location of the manufacturing facility.

Analytical Methods

Non-destructive analytical methods limit the amount of waste generated in the quality control of finished goods that contain the IPBC active. A unique method has been developed for the analysis of IPBC in plastics applications. The method is based on the determination of iodine using non-destructive X-Ray fluorescence spectroscopy (XRF). It does not require the use of solvents to dissolve the test sample or combustion as do more conventional techniques.

Environmental Fate of IPBC

IPBC is non-persistent and mobile in soil and aquatic environments. IPBC is rapidly degraded in aerobic soil and anaerobic aquatic environments.(6)

Raw materials such as IPBC, and formulated products containing IPBC were characterized regarding the potential to enter into runaway chemical reactions using the vent sizing package calorimeter shown in Figure 3.(7) This information provides valuable guidance for the safe handling and storage of raw materials and formulated products.

In addition, should the end-use application involve processing that may generate particulate or gaseous emissions, the air should be monitored by a certified industrial hygienist to ensure worker safety.

Life cycle analysis (LCA) is a management tool for evaluating the environmental performance of a product during its life cycle (cradle-to-grave). The process described above is being subjected to an LCA to estimate the cumulative environmental impacts from all stages in the product life cycle (material extraction, processing, manufacturing, packaging, distribution, use, cycling and waste disposal).

A newly developed, environmentally ‘friendly’ product must also be cost-efficient. In this case water has displaced more expensive organic raw materials. The product is effective as a fungicide in coatings at levels of 0.2 and 0.5 weight percent (Tables 2 and 3).

Water-Based BIT Formulation

Synthesis of the Active Ingredient, BITThe commercial chemical process is based on the following synthetic pathway: anthranilic acid is diazotized and then reacted with sulfur dioxide (coupling reaction) to yield dithiobenzoic acid. The dithiobenzoic acid is then reacted (chlorinated) with sulfuryl chloride and thionyl chloride in a chlorinated solvent medium to yield chlorothiobenzoylchloride (CTBC). The CTBC is then reacted with ammonia to form the heterocycle, which is purified to yield the finished BIT product.

Product Formulation

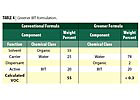

The use of organic solvents has been eliminated through the development of patented technology that facilitates the dispersion of BIT in water. The formulation of a stable 20% BIT dispersion in water has been successful. The calculated VOC content is nearly zero in the greener formulation, while the conventional formulation is at about 55% volatile organics (Table 4).

Formulated Product Manufacture

As with the greener IPBC product described above, BIT is dispersed in a closed, vented high-speed disperser, which ensures containment of any airborne substances.

Environmental Fate

BIT degrades fairly quickly in aerobic soils (half-life less than 24 hours). It is unlikely to bioaccumulate in aquatic organisms.(8)

A newly developed, environmentally ‘friendly’ product must also be cost-efficient. As in the case of the greener IPBC product, water has displaced more expensive organic raw materials. The product is effective as a microbicide in aqueous materials at levels of 0.03 and 0.05 weight percent (Table 5).

Conclusion

In this article, two examples were presented that illustrate the development and manufacture of industrial biocides for aqueous coatings that reduce negative impacts on human health and the environment. Water-based IPBC and BIT products are now available that are greener than the conventional organic solvent based formulations.

Bibliography

1. Brickweg. L.; Guillermo, A.; Jones, D.; Wills, M. Comprehensive VOC Analysis Method for Architectural Coatings. JCT Coatings Tech. 2007, 48.

2. IPCC. 2001. Intergovernmental Panel on Climate Change (IPCC) Third Assessment Report – Climate Change 2001. IPCC. Geneva, Switzerland (www.ipcc.ch).

3. Marshall, J.D.; Toffel, M.W. Framing the Elusive Concept of Sustainability: A Sustainability Hierarchy. ES&T 2005, 39 (3), 673.

4. Schuster, D. The Road to Sustainability. Chemical Engineering Progress 2007, 103 (6), 34

This paper was presented at the ICE show in Toronto, 2007.

Bibliography

1. Brickweg. L.; Guillermo, A.; Jones, D.; Wills, M. Comprehensive VOC Analysis Method for Architectural Coatings. JCT Coatings Tech. 2007, 48.

2. IPCC. 2001. Intergovernmental Panel on Climate Change (IPCC) Third Assessment Report – Climate Change 2001. IPCC. Geneva, Switzerland (www.ipcc.ch).

3. Marshall, J.D.; Toffel, M.W. Framing the Elusive Concept of Sustainability: A Sustainability Hierarchy. ES&T 2005, 39 (3), 673.

4. Schuster, D. The Road to Sustainability. Chemical Engineering Progress 2007, 103 (6), 34

This paper was presented at the ICE show in Toronto, 2007.

Report Abusive Comment