In addition, VOCs are also being reduced or eliminated from today’s formulations. All of these actions help to promote environmentally friendly and greener formulations, but at what price to performance? Concerns regarding the environment and persistent toxic materials have forced customers to search for new additives with equivalent or improved performance at the same prices they are currently paying for traditional additives. A new, environmentally friendly wetting agent for architectural coatings has been developed that can be used as a drop-in replacement for simple and modified APEs. This new, APE-free surfactant offers efficient wetting of titanium dioxide during grinding, improved freeze-thaw and viscosity stability in the formulated paint, improved foam control, better scrub resistance, and improved flow and leveling, all without contributing additional VOCs to the paint formulation.

|

| Figure 1 Click to enlarge |

Background

Most architectural paints are composed of a few basic ingredient types: an emulsion or latex, pigments and additives (Figure 1). Each material plays a vital role in the overall performance of the finished paint, so raw material selection is critical. Improper selection of any of these may drastically affect the paint properties. For example, choosing the wrong binder may result in poor durability, excessive dry times or lack of adhesion to the substrate. Similarly, a poorly chosen wetting agent or surfactant can lead to poor pigment dispersibility, resulting in loss of gloss and poor film aesthetics.

For architectural paints, surface active agents, also known as surfactants, are used to lower surface or interfacial free energies of the aqueous phase to achieve good pigment wetting for efficient grinding and consistent substrate wetting for defect-free coatings. Good wetting performance in these applications is demonstrated by low dynamic surface tension values that occur when the surfactant can migrate rapidly to newly created interfaces created during manufacturing and application. Low dynamic surface tension promotes excellent wetting on multiple surfaces and efficient pigment grinding; this, in turn, leads to improved coverage and adhesion, reduced grind times and enhanced color development.

|

| Figure 2 Click to enlarge |

Surfactants

The conversion of solvent-based coatings to water-based systems has presented the additive manufacturer with a variety of challenges. Typical surface tensions of solvent-based systems are in the 25 to 35 mN/m range, mostly due to the solvents used in these systems. Water-based coatings, on the other hand, typically have surface tensions of 50 mN/m or higher, primarily due to the high surface tension of water at 72 mN/m. When painting a substrate with a surface energy of 35-45 mN/m with a water-based system, reduction in surface tension of the coating must occur.(2) As seen in Figure 3, spontaneous wetting of a surface can only occur when the surface tension of the liquid is lower than the surface energy of the substrate. To accomplish this, surfactants or wetting agents are commonly used in water-based coating applications.

|

| Figure 3 Click to enlarge |

Pigment Dispersion

The process of preparing a pigment dispersion is typically defined as the sum of three distinct processes. The first process involves wetting the dry pigment to displace air and any other impurities from the pigment surface. Once the pigment particles are sufficiently wetted out, grinding occurs to reduce the large pigment aggregates and agglomerates to their primary particle size. The last step involves stabilizing the dispersion to enhance color and viscosity stability, as well as shock resistance and letdown compatibility.

|

| Figure 4 Click to enlarge |

For waterborne coatings, the dispersion process presents a number of challenges. For example, the high surface tension of water and the interfacial tension between the continuous water phase and the pigment must be reduced to adequately wet the pigment particles, as shown schematically in Figure 4. To reduce the surface and interfacial tensions, pigment wetting surfactants are used. These additives adsorb onto the pigment surface, reduce the interfacial tension and prepare the pigment for further adsorption of dispersion-stabilizing molecules.(3) When the surface and interfacial tensions are low, milling efficiency is improved. This results in shorter grinding times and lower energy demand to reach primary particle sizes, lower grinding temperatures and lower viscosities of the mill base, which can lead to higher pigment loadings.

Traditional wetting agents include alkylphenol ethoxylates, which have excellent ability to wet out the pigment surfaces. Due to the growing concern that APEs are endocrine disrupters and that they could adversely affect health, there is a growing trend towards replacing these materials in coatings applications. Because of their hydrophilic nature, APEs tend to stabilize foam and can cause water sensitivity issues in the final film. Use of these surfactants also leads to the use of strong defoamers to control foam which, in turn, can cause defects in the final film. Choosing the right wetting agent for pigment wetting will not only provide the most efficient milling and color development, but may also aid in preventing foam generation during manufacture and application.

|

| Figure 5 Click to enlarge |

Once the pigment aggregates and/or agglomerates have been broken down to their primary particle size, the particles must be stabilized to prevent re-agglomeration and flocculation. As seen in Figure 5, stability is usually achieved through steric and elecrostatic stabilization. Electrostatic stabilization is accomplished through electric double layers, which are formed due to the adsorbed molecules on the particle surfaces. Steric stabilization is accomplished by the interactions in the aqueous phase of hydrophilic segments of molecules adsorbed onto the particle surfaces.(3)

These stabilizing hydrophilic segments are often from surfactants containing ethoxylates of alkylphenols, neutralized alkyl phenol sulfonates or from polymeric molecules such as amine-neutralized copolymers of poly(acrylic acid). Depending on the formulation, one additive may be used for both the wetting and stabilization process. Pigment type, application parameters and cost are all factors to consider when choosing a dispersing package.

New Surfactant Development

Additives are used in architectural paints to not only wet out pigments and substrates but also to help with foam control, durability, block resistance, color development, washability or scrub resistance, and to help lower VOCs. A new, APE-free surfactant has been developed to improve these properties in a cost-effective manner while helping to minimize the VOC content of the final formulation.

|

| Table 1 Click to enlarge |

Applications Testing

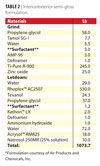

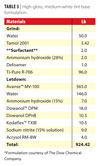

Three model paint formulations were prepared to evaluate the new APE-free wetting agent.

|

| Table 2 Click to enlarge |

These formulations can be found in Tables 1-3. This new surfactant, designated as E2010, was benchmarked against two commercially available APE-containing surfactants designated as low-foam APE-containing surfactant (LFAPE) and hydrophobically modified APE (HMAPE).

All additives were used at the recommended use level specified in the starting-point formulation.

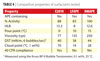

Physical properties of the surfactants tested can be found in Table 4.

All paints were prepared following the manufacturer’s specified procedure and, following formulation, were applied using a 3-mil bird bar. Viscosity measurements, an indication of paint stability, were determined using a digital Stormer Viscometer 24 hr after preparation and 2 weeks after aging at 50 °C. Blocking samples were prepared by coating the paint onto Leneta charts using a 3-mil bird bar, allowing the paints to dry for 24 hr at room temperature and then placing them face to face for 1 hr before pulling apart.

|

| Table 3 Click to enlarge |

|

| Table 4 Click to enlarge |

Gloss and contrast ratios were measured using a BYK-Gardner Spectro-Glide 45/0 Glossmeter. To perform the rub-up test, the paints were tinted with the suggested tint base, coated onto a Leneta 1B chart with a 3-mil bird bar and allowed to rest for 1 min. Rubs were done on the coated section for 30 sec, and then the charts were dried for 24 hr under controlled temperature and humidity. Once the paint cured, color differences were measured between the rubbed and unrubbed areas on the chart. A Delta E value of less than 1 resulted in a “Pass” rating.

Sag values were measured using a Leneta anti-sag meter, and leveling was determined by following ASTM D 4062 using a Leneta Leveling Test Blade.

Foam tests were conducted by agitating a sample on a Red Devil Paint Shaker for 15 min and recording the density of the paint. To calculate the percent change in foam density, the difference between the density of the unagitated samples and the agitated samples was measured.

A Washability and Wear Tester Model D10 was used to measure scrub resistance.

|

| Table 5 Click to enlarge |

Lastly, to determine the freeze-thaw stability, 300 g of paint were weighed into an 8 oz, lined can. The cans were placed in a freezer at 0 °C for 15 hr followed by a thaw at room temperature for 4 hr. The cans were then placed in a 25 °C water bath for 2 hr. Finally, the paints were stirred and a Stormer viscosity was taken. This process was repeated five times or until the viscosity could no longer be measured. The last cycle at which a viscosity could be measured is the reported value.

Results and Discussion

|

| Table 6 Click to enlarge |

Some notable features seen in Table 4 illustrate the ease of use of the newly developed APE-free surfactant. With a pour point of 0 °C, E2010 is much easier to handle in cold environments. The cloud point of E2010 is also significantly higher than the other two surfactants tested. Lastly, due to its composition, E2010 will be compliant with 40 CFR regulations, making it ideal for agricultural coatings and applications.

|

| Figure 6 Click to enlarge |

Evaluations of the ultralow-VOC interior eggshell formulation show excellent performance of the E2010 sample compared to the two APE-containing surfactants. As a replacement for the LFAPE-, or for HMAPE-containing surfactants, E2010 showed numerous benefits in the resultant coating (Table 5). These benefits include excellent gloss control, improved opacity and tint strength, as well as enhanced color acceptance and viscosity stability in tinted systems. E2010 also offers excellent scrub resistance and improved blocking resistance. All formulations exhibited excellent flow and leveling properties and equivalent foam control.

Table 6 illustrates the performance of the surfactants tested in the interior/exterior semi-gloss formulation.

|

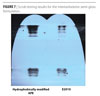

| Figure 7 Click to enlarge |

Coating evaluation showed that E2010 surfactant achieved improved leveling (Figure 6), enhanced scrub resistance, comparable gloss, opacity, color acceptance and tint strength, competitive foam control and comparable freeze-thaw stability performance over the APE-containing surfactants.

Figure 7 illustrates the scrub testing results of the semi-gloss formulation formulated with E2010 surfactant on the right and with the HMAPE surfactant on the left. When used in this formulation, the E2010 surfactant provided an improvement of 27% in scrub resistance over the APE-containing surfactant.

|

| Figure 8 Click to enlarge |

Also, as seen in Figure 8, E2010 offers enhanced foam control over the LFAPE-containing formulation, thus allowing the formulator to decrease the amount of defoamer used in the paint, leading to reduced overall formulation cost. Improved scrub resistance as well as comparable leveling, color acceptance, gloss and tint strength were also seen with the E2010-containing paint.

|

| Table 7 Click to enlarge |

VOC Measurements

The VOC contribution of E2010 to the formulated coating was measured following EPA Method 24. To perform this test, a commercially marketed, zero-VOC architectural paint was used. To this paint, 1% of the E2010 surfactant was added and the paint was subjected to the Method 24 test. The test results indicated that E2010 contributed zero VOCs to the paint.

Conclusion

The choice of wetting agents used in architectural coatings can have a significant impact when formulating low- to zero-VOC paints. A new, environmentally friendly, APE-free surfactant has been developed to assist in the formulation of these coatings while offering improved performance properties over conventional APE-containing surfactants. E2010 surfactant offers efficient wetting of titanium dioxide during grinding, improved freeze-thaw and viscosity stability in the formulated paint, improved foam control, better scrub resistance, and improved flow and leveling, all while contributing no additional VOCs to the paint formulation.

The paper was presented at the 2010 Southern Society for Coatings Technology Annual Meeting in Daytona Beach, FL.

Report Abusive Comment