Polyurethane chemistry is well established for high-performance coatings. This success over the years comes from the outstanding properties brought by polyurethane backbones such as high solvent and mechanical resistance (hardness/flexibility compromise), very good adhesion on various substrates, fast film forming and drying at room temperature, and excellent weathering resistance, provided that aromatic structures are absent from the polymer composition. These characteristics have made polyurethane-based coatings ideal candidates in application fields requiring high film appearance and resistance as in automotive car refinishing and OEM.

Over the last decades, solvent-based systems have dominated the market. However, more stringent regulations concerning VOC emissions in most countries have led paint manufacturers and raw material suppliers to develop alternative technologies to conventional solvent-based PUs, more respectful to the environment but offering the same level of performance. Thus, waterborne polyurethane coatings (1K and 2K systems) emerged at the end of the 1980s and are now being used in numerous applications.

2K Waterborne Polyurethanes: a Technical Challenge

|

| Figure 1 Click to enlarge |

2K WB PU systems truly represent a technical challenge which, 30 years ago, seemed unrealistic to overcome. In 2K waterborne polyurethane systems, an unblocked polyisocyanate hardener is dispersed in an aqueous medium containing an emulsion of a polyhydroxylated binder (polyol). The blend is applied by conventional tools (similar to solventborne systems), and the polymer network is developed after removal of water and (co)solvents (Figure 1).

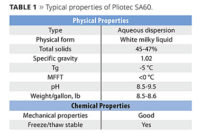

The challenge consists in avoiding significant side reactions between the polyisocyanate phase and water during a “reasonable” period of time, sufficient to let the applicator prepare the formulation and apply it. Luckily, with primary OH-functional polyols, the reactivity of the NCO groups is greater than toward water, as seen in Table 1, which limits this issue.

|

| Table 1 Click to enlarge |

The emulsification of the hardener can be obtained by high-shear mixing of a conventional hydrophobic polyisocyanate. However, this method requires specific equipment; a preferred alternative is to modify the polyisocyanate with an appropriate surfactant system to get a “spontaneous emulsification” when added into an aqueous medium. Spontaneous emulsification occurs when two immiscible liquids are put together and an emulsion is obtained without requiring additional energy (stirring and temperature), as shown in Figure 2.

|

| Figure 2 Click to enlarge |

The knowledge of the mechanisms responsible for the spontaneous emulsification of an “oil” phase into water is not complete yet and there is still intensive research aimed at better understanding the processes and parameters involved. It is generally admitted that the spontaneous emulsification of an organic solution grows through the organization of the surfactant into bilayer structures (lamellar phase or vesicles), which leads to the formation of an emulsion when destabilized.(2)

Although waterborne coating technologies are now state-of-the-art in the automotive industry for primers and basecoats, they are still limited in use for clearcoat applications, and only a few commercial systems are available. This is partly due to limitations of the first systems developed: lower film building rate due to water evaporation, water sensitivity of the hardeners, surface defects (pinholes, microfoams), etc.(3) However, new generations of raw materials and particularly hydrophilic polyisocyanates enable us now to overcome most of these weaknesses, and high-performance systems can be designed, which really compete with conventional solvent systems in terms of end-use properties.

|

| Table 2 Click to enlarge |

The objective of this paper is to compare the properties obtained with different generations of solventborne clearcoats used in the automotive coatings industry (acrylic melamine and 2K solventborne polyurethanes designed for OEM and car refinish applications) with those of a 2K waterborne system.

Experimental

Formulation and Coating Preparation

|

| Table 3 Click to enlarge |

Table 2 describes the different clearcoat types studied as well as the curing conditions. Clearcoat A is a commercial acid-catalyzed acrylic/melamine system. Clearcoat B (high-bake system) and C (low-bake system) correspond to 2K solventborne PU systems designed respectively for OEM and auto refinish applications. In this study, Clearcoat B will be considered as a reference in terms of mar resistance: in fact, previous work in our lab showed that the loss of gloss after the car wash test in the case of Clearcoat B remained below 20% after 1500 h under accelerated weathering conditions (Weather-Ometer). Clearcoat D (low-bake system) is based on a 2K waterborne formulation specifically designed to fulfill car refinish requirements (viscosity, drying kinetics and end-use properties), as will be demonstrated in the following discussion.

The polyisocyanate characteristics used for the polyurethane systems are presented in Table 3. Easaqua X D 401 is a hydrophilic polyisocyanate (hybrid structure based on HDI/IPDI derivatives) specifically designed to improve drying properties of 2K waterborne systems.(4) For the 2K polyurethane clearcoat formulation, the NCO/OH ratio was adjusted to 1.05 for the solvent-based systems (Clearcoats B and C) and 1.2 for the Clearcoat D (waterborne system).

All the clearcoats were applied using a conventional air spray gun (DeVilbiss SRI) onto a commercial “black Onyx” basecoat (dry film thickness = 12-14 µm). Paint systems were applied onto metallic substrates (aluminum panels from Q-panel) previously degreased and coated with a commercial 2K solventborne primer surfacer (DFT = 35 to 40 µm).

Experimental Techniques

All cured systems were stored at 23 °C and at 50% relative humidity before testing. Tests performed were as follows:

- Persoz hardness;

- reverse impact;

- gloss;

- solvent resistance (MEK double rub);

- nanoindentation and nanoscratch characterization;

- weatherability under accelerated conditions (Weather-Ometer); and

- acid etch resistance under Jacksonville conditions.

The nanoindentation test procedure(5) determines the mechanical characteristics of the material close to the surface (elastic modulus, hardness). The indenters used in this study are a diamond pyramid, Berkovich type, with a face angle of 115°. Both the nanoindentation and the nanoscratch tests were carried out with a Nano-Indenter XP from MTA.

Nanoscratch tests were performed following a ramp-load procedure using the normal applied load increase from 20 µN to 160 mN, at scratch velocities of 1 µm/s, using a spherical indenter (R = 7 µm). The total scratch lengths were 500 µm. Classically, height profiles before and after the scratch are collected. The penetration depth during the scratch is recorded after subtracting the topography of the undamaged coating. The remaining scratch is visualized afterwards by optical microscopy.

In this study, nanoindentation and nanoscratch tests were performed on “fresh” systems (stored 1 month at 23 °C and 50% RH) and on aged systems (after 1500 h of accelerated weathering using a Weather-Ometer).

Results and Discussion

General Properties and Final Finish

|

| Table 4 Click to enlarge |

Good balance of mechanical properties (hardness/flexibility compromise), controlled finish smoothness and brightness, and high chemical resistance are key requirements for automotive clearcoats. Table 4 presents the mechanical and optical characteristics of the different clearcoat formulations, as well as their solvent resistance measured by a MEK double rub test. The results show that the three polyurethane clearcoat systems exhibit very similar performance in terms of mechanical hardness, flexibility (impact resistance), optical aspect and solvent resistance. In particular, no difference can be seen between solventborne and waterborne clearcoats. However, Clearcoat A (acrylic melamine system) leads to lower hardness/flexibility. This behavior is characteristic of a heterogeneous crosslinking network in the case of Clearcoat A.

Mar/Scratch Resistance

In automotive applications, the damage corresponding to mar/scratch resistance is one of the most important perception problems from a customer point of view, which relates to durability performance of the coating. Mar/scratch resistance is clearly only ensured by the clearcoat layer.

|

| Table 5 Click to enlarge |

The behavior of the polymer material during scratching is a complex phenomenon, and specific tools, like nanoindentation, are required to analyze and understand the overall performance. The mechanical properties of the four different clearcoats measured by nanoindentation tests, before and after accelerated weathering, are summarized in Table 5.

In this table, E’* corresponds to the reduced elastic modulus of the coating given by where E’ is the elastic modulus of the material and n is the Poisson’s coefficient. H corresponds to the hardness value measured with the Berkovich indenter at a load rate of 3.10-2 s-1. The values for E’* and H are given for an indented depth of 1 µm. The values for the ratio H/E are also reported. H/E represents the limit strain where plastic deformation is induced by the indenter. The higher the value of H/E, the better the material will resist plastic deformation during mechanical indentation and scratch. Finally, n is the viscoplastic index of the Norton-Hoff law relating hardness to strain rate: H(1/n)

1/n = 1: the material exhibits pure viscous behavior

1/n = 0: the material is purely plastic (no influence of the strain rate on the hardness determination).

|

| Figure 3 Click to enlarge |

As demonstrated by Bertrand-Lambotte,(6) n indicates the ability of the material to heal ductile scratches: the lower the value for n, the faster ductile scratches will heal. The resistance of the clearcoats to plastic deformation and their ability to heal ductile scratches (H/E and n factors) are reported in Figures 3 and 4 respectively.

The results show that Clearcoat A (acrylic melamine system) exhibits lower elastic modulus and lower hardness, as well as lower H/E and n values, than the polyurethane systems. The fact that Clearcoat A exhibits lower hardness and elastic modulus is consistent with the Persoz hardness values obtained previously. The low H/E value indicates that Clearcoat A exhibits poorer resistance to plastic deformation during scratching. On the other hand, the lower value for n (viscoplastic index) suggests a higher ability to heal ductile scratches. This behaviour is undoubtedly related to the motion of the macromolecular chains in the conditions of test and indicates a broad glass transition consistent with a more heterogeneous polymer network compared to polyurethanes.

|

| Figure 4 Click to enlarge |

Interestingly, all the polyurethane systems again exhibit similar mechanical properties as determined by nanoindentation. In the case of the “fresh” samples, Clearcoat C shows slightly higher hardness and elastic modulus than Clearcoats B and D, but similar values for n and H/E. After accelerated weathering, all clearcoats tend to harden slightly. This behaviour is probably due to physical aging of the polymer network. Clearcoats C and D present equivalent properties.

The shape and morphology of the scratches performed on the different clearcoat systems before aging are shown in Figure 5. All the systems present at the beginning of the scratch (for low indentation forces/depths) a ductile-type behavior, which turns to brittle for higher indentation depths. Ductile/brittle transition is governed by both size and energy criteria: in other words, a crack will appear in the material if the energy brought to the material exceeds the energy required to develop a new surface (following Griffith’s approach), and will propagate if the characteristic size of the sample is at least twice the dimension of the plastic domain induced at the front of the deformation as demonstrated by Puttick.(5-6) The ductile/brittle transition is clearly seen on the pictures with the first “fish bones” along the scratch groove.

|

| Figure 5 Click to enlarge |

Brittle failure is obviously a key property in terms of scratch resistance since it will affect the protection role played by the clearcoats (points of failure will let chemical agents penetrate the whole coating system and may cause delamination, hydrolysis reactions, etc.). In order to quantify the performance of the clearcoat toward brittle scratching, we have reported in Table 6 the length in µm of the plastic scratch before the first crack appears for each clearcoat before and after aging.

Before aging, the ranking of the different systems in terms of resistance to brittle failure is the following: Clearcoat C > Clearcoat B > Clearcoat D > Clearcoat A. After accelerated weathering, a decrease in terms of resistance to brittle failure for all the systems is observed. This phenomenon is consistent with the “hardening” observed by nanoindentation measurements and is particularly pronounced in the case of Clearcoats A and C. Whereas the results for Clearcoat A are to some extent expected and due to the lower stability of the acrylic/melamine network in accelerated weathering conditions (compared to polyurethanes), the drop in the case of Clearcoat C is more surprising. However, C still exhibits slightly better performance among the systems tested even after accelerated aging. Clearcoats B and D show the same performances, which is particularly interesting considering the excellent performance of Clearcoat B obtained by the car wash test.

|

| Table 6 Click to enlarge |

Weathering and Acid Etch Resistance

The interest for technical improvement on automotive clearcoats has been focused in the recent past on durability towards “environmental” conditions, and particularly etching resistance (caused by both acid rain in industrialized regions and natural fallout in the form of bird droppings). Resistance to etching is highly linked to the crosslink density of the polymer network and also to the hydrolytic stability of the coating.

|

| Table 7 Click to enlarge |

In our study, resistance to weathering/UV exposure of the different clearcoat systems was determined by recording the gloss retention after 1500 h in accelerated conditions (Weather-Ometer). As for acid etch resistance, samples were sent to Jacksonville, FL, for 14 weeks and gloss retention recorded accordingly (only Clearcoats C and D were tested). Results are reported in Table 7.

Atmospheric conditions recorded at Jacksonville during the test are given in Table 8.

|

| Table 8 Click to enlarge |

As far as gloss retention is concerned, results obtained show good performance in terms of UV resistance for all systems studied (note that all systems contain UV light stabilizers). Concerning acid etch resistance, the performance of the two low-bake polyurethane systems (C and D) are obviously very good. Interestingly, Clearcoat D (waterborne) outperforms Clearcoat C since almost no visual degradation is observed after almost 4 months in an acidic environment.

Conclusion

Waterborne 2K polyurethane systems have been available on the market for 10 years. The choice of raw materials especially designed for this technology has evolved to meet formulators’ and end-users’ needs.

This study demonstrates that 2K waterborne polyurethane clearcoats can be a technology of choice in automotive clearcoat applications in order to combine high-demanding requirements (such as mar/scratch resistance, final finish, etc.) and sustainability development concerns.

This paper was presented at The Waterborne Symposium, Advances in Sustainable Coatings Technology, 2010. The symposium is sponsored by The University of Southern Mississippi School of Polymers and High-Performance Materials.

Report Abusive Comment