Inks comprised of carbon nanotubes are commercially available from a variety of sources. However many, if not all, of these CNT inks have properties that limit their use in printing with common commercial printing equipment at high rates. Some of these limitations are listed below.

- Most inks have very low CNT concentration, requiring multiple passes to achieve the desired CNT deposition, resulting in cost and resolution penalties.

- Oftentimes, non-volatile dispersants and surfactants are used, which must be removed in order for the optimal performance of the CNT to be realized. This requires an added rinsing operation and/or a high-temperature baking process. These added steps increase cost and may not be compatible with other layers in the device.

- Most CNT inks do not have sufficiently high viscosity for commercial printing processes such as screen, flexo or gravure.

- Traditional techniques that have been used to coat CNTs, such as spin coating and aerosol spraying, are not well suited for roll-to-roll coating. They also require an additional step of subtractive patterning via photolithographic etching or laser ablation. Ink jet printing has been successfully demonstrated for CNTs, but this technique is better suited for prototyping versus high-rate manufacturing.

These limitations have been significant barriers to commercialization of CNT inks for printed electronic applications. The ability to print CNT inks in large areas, at high rates, with standard commercial printing equipment, will enable a wide range of printed electronics applications.

Novel CNT Inks

Using novel chemistry, new CNT coating fluids and inks have been developed by SouthWest NanoTechnologies (SWeNT®) that overcome many of the limitations described above. These inks use a proprietary technology, developed by CHASM Technologies, called V2Vä Ink Technology. V2V (Viscous-to-Vapor) employs unique chemistry that has several features that make printing CNTs safe and easy to use for a variety of commercial coating and printing techniques. These features include:

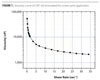

- Ability to tailor ink viscosity over the workable range of 50 to 5000 cP (compatible with screen, flexo and gravure);

- No residual surfactants or dispersants need to be removed, as the viscous fluid is completely vaporized during standard drying conditions (100 °C);

- No CNT airborne species;

- Direct printing means no need for subtractive patterning.

Overall, V2V technology overcomes the limitations of prior state-of-the-art CNT inks and fluids, allowing printing with standard commercial equipment. This greatly expands the range of applications for CNTs.

V2V technology simply combines a CNT paste, containing no surfactants or dispersing aids, and a viscous media. When combined and blended together, the resultant CNT ink fluid is a stable dispersion of CNTs that can be easily printed with commercial printing equipment.

|

| Figure 1 Click to enlarge |

The V2V viscous media completely vaporizes at standard drying temperatures, leaving no significant traces of residual material that need to be removed in post processing or that affect the performance of the deposited CNT in the dried coating. The media viscosity can be easily adjusted to the desired range for the specific coating application through small chemistry changes. Changes to the viscous media component chemistry can also be altered to affect drying or substrate compatibility. Coating the ink on polymeric materials may require changes to the viscous media formulation to minimize dilution and salvation effects of the ink fluid into the substrate layer. This is a straightforward process using the V2V technology, as the chemistries involved are compatible with a wide range of substrate materials.

|

| Figure 2 Click to enlarge |

SWeNT CNT ink fluids have been successfully demonstrated on commercial screen printing equipment with relatively high CNT loadings (1 g/L). Commercial applications such as LED lighting and touch pads/screens are being investigated. Figure 1 is a representative curve of ink developed for a screen print application. Figure 2 is the ink being printed using commercial screen-printing equipment. Figure 3 shows screen-printed electrodes using the V2V CNT ink. Figure 4 shows an SEM of screen-printed film showing the CNT structure.

|

| Figure 3-4 Click to enlarge |

Conclusions

Employing a novel chemistry, CNT inks can now be printed using standard commercial printing equipment. The new fluids have several key advantages over current state-of-the-art CNT fluids:

- CNT concentrations, up to at least 1 g/L, which allow single-pass printing operations or higher coverage per pass;

- No residual viscosity modifiers, surfactants or dispersing aids to remove to achieve optimal performance. 100% volatile ink base;

- Rheological properties that allow potential line speeds up to 300 ft/min.;

- Easy to dry at relatively low temperatures (<100 ºC), with conventional ovens and dryers;

- Compatible with a wide range of CNT materials. Demonstrated with functionalized and non-functionalized metallic and semi-conducting types;

- Compatibility with a variety of common substrates including polyester, polycarbonate and paper.

- Because of the fluid properties, direct printing is possible – no need for masking;

- Direct printing is safer than spray coating. No airborne CNT particulates.

V2V is a trademark of Chasm Technologies, Inc. Patent pending.

Report Abusive Comment