Point of sale (POS) tinting systems have been in existence for over 50 years, and there have been evolutionary changes in paints, colorants and equipment over the years to meet technical, economic and regulatory challenges. However now is a time of major change in colorants for POS systems as there are desires for better lightfastness, larger color gamuts and increased opacity. Equally important are regulatory and marketing requirements to meet VOC and APE surfactant restrictions. Colortrend USA LLC has developed the Colortrend® 808 line of colorants to meet these desires and needs.

These products are free of APE surfactants and are considered no-VOC colorants. (More about the meaning of no-VOC will be covered below.) The 808 line consists of a subset of colorants that are counterparts to the industry-standard Colortrend 888 colorants. This facilitates the transition from conventional high-VOC water/glycol colorants to the newer no-VOC colorants. It is very difficult to change the set of colorants because of the accumulation of color-matching formulas using the set of colorants.

Changes would necessitate developing new color formulas, not only for colors currently featured in store displays, but also for past color matches. Because of this, most POS systems used the same lineup of colorants for many years. However, now users are considering changes to their colorant lineup. Evaluation of newer colorants to expand color space, provide better lightfastness and achieve greater opacity is taking place. Users are realizing the benefits of making changes, and the Colortrend 808 line consists of matches to traditional colorants but also adds a number of newer colorant options.

VOC Issues

One of the most important features of the Colortrend 808 colorants is that they meet the need for no-VOC colorants. The issue of VOCs and colorants has been unclear for a number of reasons. First is the terminology used. The terms no-VOC, low-VOC, zero-VOC and ultralow-VOC have no official meanings for colorants. For the purposes of this article, the term no-VOC will be used. Also, up until this time VOC regulations applied to paint and not colorants. The colorants used at POS have not counted in the assessment of a tinted paint’s VOC, and levels were not regulated. One reason is that paint VOCs were fairly high in the past, and the contribution from colorants was not as important.

Now that paints have been successfully developed with lower VOC levels, the contribution from colorant can be significant, especially with deeper colors using 10 to 12 ounces of colorant per gallon. There is also a question regarding the method for determining VOC. For several years a methodology known as EPA 24 or ASTM 3960 has been in use. This method was developed for testing materials containing conventional levels of VOC. For paints and colorants with very low VOC levels, imprecision in the method can result in inaccurate results. Newer methods, such as ASTM D 6886-03 or ISO 11890-2, are more appropriate for very low-VOC materials and are now used. A future methodology is to take into account each ingredient’s potential for ozone formation rather than to treat all volatiles as equal. These reactivity-based methods are under study, and we will hear more about maximum incremental activity (MIR) techniques as they are developed and considered by regulators.

Another issue with VOC for paint and colorants is that there are multiple regulatory bodies involved. There are the national organizations such as the U.S. EPA and Environment Canada (EC). State and regional agencies have also been active in setting limits – mostly for paint to date. Examples are the California Air Resources Board (CARB), the Ozone Transport Commission (OTC) in the Northeast, and the South Coast Air Quality Management District (SCAQMD) in California. SCAQMD has been considering VOC limits for colorants and has recently announced a limit of 50g/L for 2013. The 808 colorants are well under this limit and are determined to be zero VOC by calculation under the EPA 24 method.

Opacity and High-Strength Colorants

In architectural POS tinting, paint bases with fixed TiO2 levels are used. Because of this, there is not the opportunity to optimize pigment or TiO2 loading for each individual color as is more the case for in-plant coloring. A color is made in the highest TiO2 level base possible, but the limitation is the amount of colorant that can be added to a base. In addition, the colorants traditionally used in POS tinting systems do not necessarily contain a high level of pigment. The black colorants and most of the organic pigment colorants contain a fairly low level of pigment. This was originally done to facilitate precise color reproduction of light colors in small container sizes, e.g. quarts. If a colorant was too strong, that is, had a high level of pigment, it would be difficult to make very light colors given the dispensing machine increments and accuracy originally available.2

|

| Figure 1 Click to enlarge |

With modern dispensing equipment these limitations are not as severe. Therefore, we have developed a series of higher strength colorants in the Colortrend 808 line. The pigment content and tinting strength of these colorants is from 1.5 to 3+ times as strong compared to traditional colorants. Therefore, the amount of pigment in the 12 ounces of colorant added to a neutral base can be about 2-3 times the amount of total pigment usually added, thereby achieving increased opacity. In addition, some colors can now be made in a base with a higher TiO2 level because less colorant is needed. For example, a color using 3-4 ounces of colorant per gallon of Deep base (which would need, for example, 10 ounces in Medium base) can now be made in Medium because it requires only 4-5 ounces of stronger colorants in Medium base.

Another benefit of higher-strength colorants is that as less colorant needs to be added to a base, there is a decrease in any paint film effects caused by other materials in the colorant. There can also be a reduction in the cost of tinting by the use of high-strength colorants.

|

| Figure 2 Click to enlarge |

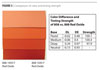

As an example, Figure 1 contains a comparison of a conventional-strength and a high-strength colorant. On the left is the product Colortrend 888-5511 D green added to a white base. On the right is Colortrend 808-5555 DXE from the Colortrend 808 product line. Equal amounts of the colorants were added to the paint base. The high-strength green is three times stronger than the regular green. High-strength counterparts are available for black, green, blue, magenta and violet colorants (colorants B, D, E, V, J).

Figure 2 illustrates the benefit of newer colorants using more opaque pigments and colorants with higher pigment content. This is a comparison of a red color matched both with conventional red Colortrend 888-0836 R on the left side and on the right side using a higher strength red Colortrend 808-0755 REE. Here the drawdowns were made on black and white cards using paints tinted with 12 ounces of colorant per gallon of neutral base.

The appearance can be quantified by measuring the contrast ratio (CR). The color on the left has a CR of 85, while the color on the right made with REE has a CR of 98. Two or three coats of the paint on the left would be required to match the opacity of a single coat of the right side paint.

Comparison to Current Colorants

|

| Figure 3 Click to enlarge |

A most important question in adopting the new Colortrend 808 colorants is how they compare to previous colorants. The Colortrend 808 products, although no VOC, are still universal colorants, meant to tint both latex and alkyd paints. Although their use may be decreasing, there are still conventional alkyds and stains in use, and it would be inconvenient for a paint store to need two sets of colorants and therefore two dispensing machines for tinting needs. The Colortrend 808 colorants were extensively tested for compatibility in a wide range of architectural coatings and confirmed to be useable in the same range of coatings as Colortrend 888. Effects of Colortrend 808 on paint film properties such as gloss, blocking and sag resistance were comparable to Colortrend 888 colorants. Viscosity drop in paint, although still present to some extent, was more uniform among colorants of the Colortrend 808 line than with Colortrend 888.

|

| Figure 4 Click to enlarge |

The Colortrend 808 colorants are meant to be used in the same color formulas as the corresponding Colortrend 888 colorants, with no adjustments needed because of the colorant change. To ensure this, Colortrend 808 colorants are made from the same pigments and matched to the same color and strength standards as their Colortrend 888 counterparts. Production batches of Colortrend 808 have been checked for linearity vs. Colortrend 888 standards in several sets of commercially available paint, using bases from white to neutral. Typical results are shown in Figure 3, which include tinting strength and CIELAB DE data.

Expanded Color Space Coverage

The flexibility to increase the lineup from the traditional 12 colorants allows for expanded color space coverage. Brighter oranges, reds and purples are possible. Figure 4 shows a CIELAB A* B* color diagram (yellow at the top, blue at the bottom, green to the left, red on the right) with an outline of the range of colors possible with the traditional set of colorants. The space is expanded in the red area with the use of Colortrend 808 colorant REE red in place of the regular red R, and the use of magenta Colortrend 808 QME magenta in place of magenta V. Similar expansions are possible in the violet and orange areas with the use of the newer colorants.

Colortrend 808 also includes a series of mixed metal oxide pigments such as cobalt blue, cobalt green, bismuth vanadate yellow and others for use in coloring inorganic coating systems or other coatings requiring very good lightfastness. In the past, the only inorganic colorants available for some of these applications were the iron oxides. Now with additional colorant types the range of colors possible is greatly expanded over that achievable with only red and yellow oxide.

Summary

Colortrend 808 colorants are the colorants of the future and are being adopted now by a number of paint companies. The requirements of no- or very low-VOC and APE-free colorants are met. These products are universal colorants, so everything now tinted with conventional colorants can still be colored. The product line consists of a wide variety of pigment choices. Subsets of colorants can be chosen in modular fashion to allow a company to emphasize color space, opacity, lightfastness and cost, depending on their market needs. There is the set of 12 colorants corresponding to the most common conventional colorant set, allowing easy transition to no VOC with no color rematching. Overall the Colortrend 808 colorants present many options to meet marketing, regulatory and technical goals.

Report Abusive Comment