Waterborne acrylic latexes can be prepared via batch, seeded, in situ seeded and continuous polymerization. In this investigation, the seeded process was used for the preparation of nano-size seeds with a target average particle size of Dn ≤ 50 nm. These nano-size seeds were then used for the preparation of ultrafine full latexes via a semi-batch process with a target average particle size of Dn ≤ 100 nm. Surfactant concentrations were optimized to ensure minimal grit and coagulum and clean reactions with the final surfactant concentration of 0.45 parts per hundred of monomer (phm) in the final latex. Additionally, these ultrafine dispersions were evaluated for latex film appearance, gloss, adhesion and water pick-up performance. Finally, the dispersions were utilized to prepare semigloss paints to illustrate the effect of particle size on select paint properties (i.e., appearance, gloss, block and adhesion).

|

| Table 1 Click to enlarge |

Introduction

Waterborne coatings are applied on wood, metal, plastics, flooring and paper substrates to improve their aesthetics and provide protection from light, salt, heat and moisture. The key ingredients in a coating formulation are the pigment and binder. Pigments impart opacity, durability, anticorrosion and rust inhibition to the coating; the latex binder forms a film and holds pigment, filler and other components together, and additionally protects the substrate. The binder also contributes to the gloss, blocking and adhesion of the film. Surfactants play a critical role in binder preparation and are used to control particle size, reaction kinetics and latex stability.(1,2) However, surfactants can negatively impact the block, scrub, adhesion and gloss properties of the coating, so it is generally desired to utilize minimal levels of surfactant and nano-size particles to circumvent these issues. Our investigations focused on screening various surfactants for making ultrafine latexes and determining the impact of these surfactants and latexes on paint properties.

|

| Table 2 Click to enlarge |

Surfactant Selection

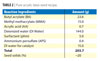

A surfactant is a key ingredient in latex preparation. Four types of surfactants were selected for the acrylic seed and ultrafine full blown (FB) latex preparations. The benchmark surfactant utilized in the experiment was DowFax 2A1™ (DPOS). DPOS was selected as a control, as it is claimed in the literature to generate ultrafine particles at low surfactant use levels and offer excellent colloidal stability. Three types of AEROSOL® surfactants from Cytec Industries (i.e. sulfosuccinamates, monoester sulfosuccinates and diester sulfosuccinates) were also evaluated. The products included AEROSOL 22 (tetrasodium N-(1,2-dicarboxyethyl)-N-octadecyl sulfosuccinamate, 22), AEROSOL 18P (disodium Noctadecyl sulfosuccinamate, 18P), AEROSOL A-102 (disodium ethoxylated alcohol [C10-C12] half ester of sulfosuccinic acid, A-102), AEROSOL EF-800 (proprietary sulfosuccinate surfactant mixture, EF-800), AEROSOL MA-80 (sodium dihexyl sulfosuccinate, MA-80) and AEROSOL OT-75 (sodium bis (2-ethylhexyl) sulfosuccinate, AEROSOL OT-75). Table 1 gives an overview of the various surfactants, select properties and features.

Experimental Results and Discussion

Seed Preparation and Characterization

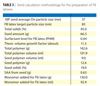

Acrylic seed batches of 20% solids were prepared via a batch process (Table 2). This seed recipe was elected with goals of achieving a Tg ~14 °C binder, and seed particle size target was 40 to 50 nm at 5 phm surfactant use. The deionized water and surfactant solution were heated to 82 °C and mixed with an A310 impeller. At 50 °C bath temperature, the monomer solution was charged to the reactor. At a 75 ºC bath temperature, the initiator was charged and the agitation speed was increased from 200 rpm to 320 rpm. Following 1.5 h of reaction, the batch temperature was dropped to 40 °C. The seed was drummed out and filtered through a finer mesh filter for grit.

|

| Table 3 Click to enlarge |

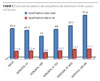

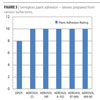

All seed latexes achieved the desired conversion to 20% solids and evidenced nil to very minimal grit. Seed particle sizes are detailed in Figure 1. AEROSOL 18P produced seed particles of 37 nm and exhibited no obvious negative process artifacts (i.e., minimal aggregates, grit and coagulation). The fine seed particles, narrow size distribution and clean process attributable to AEROSOL 18P could possibly be explained as follows: (a) the use level of 5 phm is sufficient for the seed particle full coverage; (b) the AEROSOL 18P diffusion rate fits quite well with the seed particle formation and its growth; and/or (c) the molecule anchored well and was not easily displaced when the seeds were mixed and sheared during polymerization.

The AEROSOL 22 also yielded a small seed particle of 47 nm. Additionally, no coagulum and grit were observed. It is speculated that AEROSOL 22 has less affinity for the monomer droplets and poor pre-emulsion stability but possesses a higher affinity for the particle and its stability.

AEROSOL A-102 yielded a seed particle size of 49 nm. AEROSOL A-102 offers a stable pre-emulsion, and this is highly desirable for various EP process schemes where reaction ingredients are charged from a single line and tank. This better emulsion stability means that AEROSOL A-102 has a stronger affinity for the acrylic monomers. Therefore, at any given time during polymerization, it is less available for particle protection and stability.

|

| Table 4 Click to enlarge |

Seed particles prepared with DPOS were 50 nm, and there was no reactor build-up or grit observed.

The AEROSOL EF-800 surfactant produced seed particles of 55 nm, which was greater than the desired size. The pre-emulsion stability was poor compared to DPOS but better than AEROSOL 18P and AEROSOL 22. The larger size particles and build-up on the reactor blades are probably attributable to the lower affinity of this surfactant for the acrylic seed particles.

The AEROSOL OT-75 surfactant yielded a final seed particle size of 55 nm. It is hypothesized that the larger size seed attributed to AEROSOL OT-75 limits its availability to support the stability and growth of the primary particle. This higher emulsion stability and more solubility within polymer particle core could mean that AEROSOL OT-75 possesses limited ability to support particle nucleation and its growth.

|

| Table 5 Click to enlarge |

The AEROSOL MA-80 was selected to facilitate the preparation of larger size particles, yielding a seed particle size of 72 nm. One could expect that due to its high CMC, AEROSOL MA-80 would be expected to produce bigger size particles.

Ultrafine Full Blown Latex Preparation and Characterization

The amount of the seed for the FB latex for AEROSOL 18P and other seed batches was calculated using Table 3, and for AEROSOL 18P it was 66.5 grams. The FB latex theoretical average particle size was 85 nm. The surfactant from seed was 0.6 g, and this overall amount was used in each batch and was 0.45 phm.

|

| Figure 1 Click to enlarge |

The FB latex recipe is given in Table 4. Initially, DI water was added to the seed and the seed gently mixed. After DI water addition, the seed was then mixed for 2 more min and charged to the reactor. After the seed solution charge, the process conditions for the FB latex were similar to the seed preparation with the exception that the monomers were charged over 2.5 h.

Latex characterizations are given in Table 5. The theoretical and experimental solids are in good agreement. Batches were rated Pass/Fail, with Pass designating minimal coagulum, grit and residual monomers, and Fail designating that coagulum, grit or residual monomers exceeded polymerization process norms. The AEROSOL OT 75 batch was the only failure, as it coagulated during polymerization. The control latex prepared from DPOS yielded a particle size of 110 nm. Latexes prepared from the AEROSOL 22 and AEROSOL 18P sulfosuccinimate surfactants evidenced particle sizes of 87 and 88 nm respectively, and grit, coagulum and reactor build-up were low (AEROSOL 22 was 0 and AEROSOL 18P was 0.4 g). The particle sizes of latexes prepared from the sulfosuccinate surfactants AEROSOL A-102 and AEROSOL EF-800 were 125 and 93 nm, respectively, and additionally, these products evidenced 0 and 2 g coagulum. The AEROSOL MA-80 surfactant-based latex produced a particle size of 180 nm with some fine particles. The viscosity of all the final latexes was below ~50 cps, which is desired by latex and paint producers as this facilitates easy transfer, addition and mixing.

|

| Figure 2 Click to enlarge |

To assess surfactant influence on latex properties, film drawdowns were prepared on Leneta paper. The films were 2.5 mils wet and were initially dried for 1 min at room temperature and then placed in an oven at 107 °C for 5 min. The AEROSOL 22 was continuous and transparent, and the AEROSOL MA-80 film was hazy and continuous. All films based on the other surfactants evidenced some degree of mud cracking (i.e. leaf type morphology). Latex film adhesion to glass and Leneta paper was investigated per ASTM D 7234-05, and all films evidenced excellent adhesion. The surfactant influence on the freeze/thaw (F/T) stability of the latex was assessed. Only the latex based on the 18P passed the desired 3 F/T cycles.

Latex Water Uptake

|

| Figure 3 Click to enlarge |

Latexes used as binders in exterior paints require good water resistance, and surfactants can greatly influence water intake. To assess various surfactants’ influence on this property, 1 mil dry films were prepared on glass, and film samples were dried at 107 °C for 5 min and then aged overnight in a controlled humidity and temperature room (CHT-50% humidity at 24 °C). The glass panels were then submerged into a water bath and observed and monitored over a 4-h period. Results are shown in Table 6. The good to excellent water resistance properties of these latexes could be due to: (a) lower surfactant use; (b) surfactant and polymer compatibility and (c) ultrafine particles.

Latex Gloss Properties

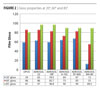

Dry latex films (1 mil) were prepared on Leneta paper. The films were dried 60 s at RT, and then dried in an oven above 90 °C for 5 min. Films were aged in the CHT room. For each film, 20°, 60° and 85° angle gloss was measured (Figure 2). The AEROSOL 18P and AEROSOL 22 surfactants yielded the best overall results and were closely followed by AEROSOL A-102, EF-800 and DPOS products. The AEROSOL MA-80 latex did yield a smooth and continuous film. However, it also yielded the poorest 20° gloss performance, and this lower gloss is attributable to large latex particle size.

|

| Figure 4 Click to enlarge |

Semigloss Paint Preparation - Attributes and Properties

The latex pH was raised to 8 and the latex was added to the semigloss grind to prepare paints (51.7 % solids and 24% PVC). Paint films, 2.5 mil wet and 1 mil dry, on Leneta paper and glass surfaces were prepared. Paint films were then conditioned for 1 day and for 1 week in a CTR room. Paint films were continuous and their surfaces smooth. These paint films were then tested for block, gloss and adhesion properties.

Paint Block Performance

Coupons were prepared and used for block resistance properties at 24 °C and 40 °C. Block performance is rated on a scale of 0 to 10, with 0 meaning no separation and 10 meaning complete separation. The data is presented in Figure 3. Paints prepared from AEROSOL 18P and AEROSOL 22 showed the best performances and these were followed by DPOS-containing latex. The block property associated with the AEROSOL MA-80, AEROSOL EF-800 and AEROSOL A-102 was poor. It is hypothesized that AEROSOL 18P and 22 are more compatible in the polymer matrix.

|

| Figure 5 Click to enlarge |

Paint Gloss Properties

Paint gloss can be influenced from various components of the paint formulation. To assess the influence of surfactant type and amount, as well as latex particle size on paint gloss, gloss was measured (Figure 4). The 20°, 60° and 85° gloss evidenced similar ranges. Thus, the latex particle size between 80 nm and 120 nm had no apparent effect on paint gloss properties.

Paint Adhesion Properties

Semigloss paint adhesion was measured via ASTM D 7234-05 cross-hatch method. Adhesion performance is rated on a scale of 0 to 10, with 0 meaning no adhesion and 10 meaning nothing was removed. After 8 days of CRT conditioning, both the sulfosuccinamates (AEROSOL 18P and AEROSOL 22) and sulfosuccinates (AEROSOL A-102, AEROSOL EF-800 and AEROSOL MA-80) surfactant-containing paints exhibited excellent adhesion. The adhesion of the DPOS control was also good, but slightly lower (Figure 5).

Conclusions and Summary

Nano-size seeds of ≤ 50 nm and 20% solids were successfully prepared utilizing AEROSOL 22, AEROSOL 18P, AEROSOL A-102 and DPOS surfactants. A semi-continuous polymerization process was successfully exploited to prepare ultrafine (nano) latexes of £ 100 nm at ultralow (0.45 phm) surfactant use levels with AEROSOL 22, 18P, A-102 and EF-800. 18P latex also offered better F/T stability opposite to DPOS. These ultrafine latex films evidenced excellent aesthetics, gloss, adhesion and low water intake. Latexes of both less or greater than 100 nm particle size offered excellent suitability with and compatibility towards the semigloss paint grind. Paint film surfaces were smooth and glossy, and cross-hatch adhesion performance was also exceptional. Paints prepared from AEROSOL 22 and AEROSOL 18P-based latexes also yielded excellent block resistance properties.

This article was presented at the 38th Annual Waterborne Symposium in New Orleans, LA.

For more information, e-mail custinfo@cytec.com.

Report Abusive Comment