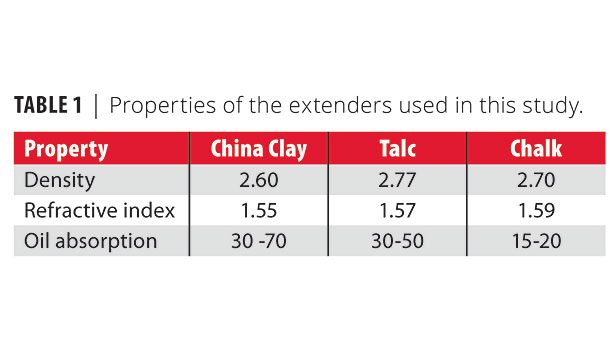

Experimental

Table 1 shows the properties of the different types of extenders used in this study. China clay/kaolin is a clay material with a platy structure; its chemical composition is Al2Si2O5(OH)4. Talc (Mg3Si4O10(OH)2 is hydrated magnesium silicate and exhibits useful flatting and anti-settling properties. Platy talcs improve the toughness and durability of paint films. Calcium carbonate, sometimes called chalk (CaCO3), exhibits good flatting properties.

The following experimental samples, with different extender combinations, were tested:

| Sample 1: China clay/talc (70/30) |

| Sample 2: China clay/talc (75/25) |

| Sample 3: China clay/talc (85/15) |

| Sample 4: China clay/talc/chalk (70/10/20) |

Primer Preparation

Alkyd resin was dissolved in solvent, and then the wetting, dispersing additives and anti-settling agent were added one by one under high shear in a high-speed stirrer (950-1180 rpm). The resin solutions along with the additives were mixed for 15 min. After thorough mixing, pigments, anti-corrosive pigments and extenders were added one by one under high shear in the high-speed stirrer. The mixture was thoroughly mixed for 10 min after the addition of all ingredients. The premixed samples were dispersed and the fineness of gauge was maintained between 10-15 microns for all samples. In the letdown stage the remaining materials (polyvinyl butyral solution, nitrocellulose solution and additives) were added to the dispersion. The addition was carried out with stirring. The final primer was allowed to mature for a minimum of 1 day before continuing the study.

System Application

The primer was applied using a DeVilbiss HVLP gun with a nozzle diameter of 1.8 mm. After scuffing (P320-400) the primer, the basecoat was applied, followed by clearcoat.

Test Methods

The primer filler samples prepared using different extender combinations were evaluated for the following properties:

| Dry adhesion, ASTM 3359 Method B |

| High-pressure humidity test (SAAB STD-3976-98) |

| Conical mandrel test (ISO-6860) |

| Cylindrical mandrel test (ISO -1519) |

| Erichsen cupping test (ISO -1520) |

Results and Discussion

Dry Adhesion (ASTM D5539/ISO2409)

All the experimental undercoats were applied directly over a mild steel substrate as well as over wash primer, and the same were sanded after sitting overnight. Then two different waterborne basecoats were applied over the scuffed, smooth surface, followed by application of a solventborne clearcoat. The applied systems were tested for adhesion after 24 h, 7 days and 15 days. The adhesion was judged on a scale of 0B-5B, where 5B = no failure; 4B = 0-5% failure; 3B = 5-15% failure; 2B = 25-35% failure; 1B = 35-65% failure and 0B = above 65% failure. Table 2 shows the adhesion results.

The results show that interlayer dry adhesion properties improved with the reduction of talc. Samples 3 and 4, which contained lower quantities of talc (around 10-15% of total formulation), performed better. On the other hand, an increase in the quantity of China clay improved interlayer adhesion properties.

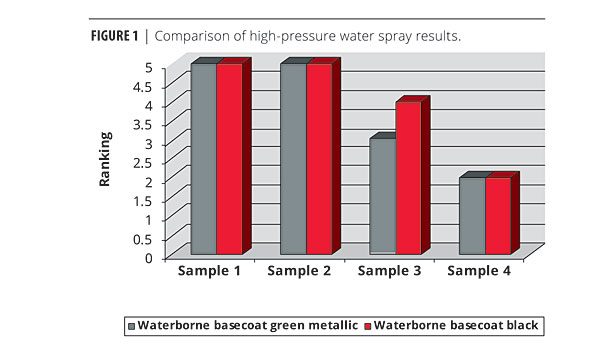

High-Pressure Water Test

The applied systems, based on two different basecoats, were tested for high-pressure water spray as per the SAAB method. It is essential to evaluate adhesion properties with different extender combinations, especially combinations with platy structures.

Figure 1 illustrates the results. A distinct difference is observed in the case of interlayer adhesion, especially with the black shade. The results also indicate improvement with the reduction in talc by increasing the quantity of China clay. However, the effect of these primer samples is the same over metal and wash primers.

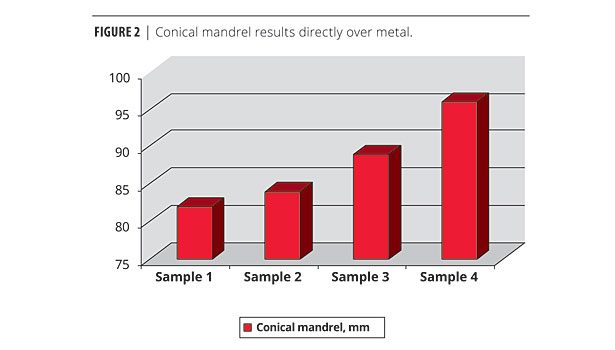

Elastic Properties

The samples were checked for elastic properties (primer alone) after 7 days curing at room temperature. The experiments were carried out over bare mild steel substrate and over wash primer. The results of the conical mandrel (ISO 6860) test are shown in Figures 2 and 3. Note: Length of cracking is measured in mm, for the conical mandrel test. The lesser the unit, the better the flexibility.

Figures 2 and 3 show that the conical mandrel bend test improved with the reduction of talc and an increase in China clay. Samples 3 and 4, which contained smaller quantities of talc (15% and 10% respectively), performed better.

Table 3 shows the results of the cylindrical mandrel test (ISO 1519). Table 4 shows the results of the Erichsen cupping test (ISO 1520).

Conclusion

The above study indicates that the platy-structured extender combinations play a vital role on dry adhesion, especially interlayer adhesion properties. Among the extenders, both a reduction of talc and an increase in China clay improved dry adhesion and conical mandrel bend test properties. The rest of the tested elastic properties remained at the same level, irrespective of variations in individual quantities of extender. n

Acknowledgements

Special thanks to Dr.Sudhakar Dantiki, Managing Director AkzoNobel Automotive & Aerospace Coatings India Pvt Ltd., and management who allowed the use of instrumentation.

References

1. Bentley, J.; Turner, G.P.A. Introduction to Paint Chemistry and Principles of Paint Technology. ISBN 0412723204 1997.

2. Talbert, R. Paint Technology Handbook. ISBN 1574447033, 2007.

3. Woodbridge, P.R. (Ed) Principles of Paint Formulation. ISBN 0412029510, 1991.

4. Deer, W.A.; Howie; Zussman, J. An Introduction of Rock-Forming Minerals, 2nd edition, Harlow, Longman ISBN_0-582-30094-0, 1992.

5. Ullaman’s Encyclopedia of Industrial Chemistry 6th edition, talc.

6. American Society for Testing and Materials. ASTM D 3359 Standard Test Method for Measuring Adhesion by Tape Test; Philadelphia, PA, 1998.

7. SAAB STD3976-98 assessment of adhesion high-pressure water test.

8. The mineral kaolinite-mineral galleries.

9. Weismantel, G.E. Paint Handbook.

10. The scratch adhesion test: An elastic-plastic indentation analysis by P.J. Burnett and D.S. Rickerby Materials Development Division, Harwell Laboratory, Didcot, Oxon. OX11 0RA U.K.

11. Wypych, G. Handbook on Solvents , William Andrew Publishing, 2001.

12. Wypych, G. Handbook of Fillers , William Andrew Publishing, 1999.

13. Mezger, T.G. The Rheology Handbook, published February 2011 ISBN: 9783866308640.

14. Westhues, U.M. Polyurethane Coatings, Adhesive and Sealants, November 2007.

15. Muller, B. Understanding Additives , January 1970 ISBN: 9783866308688.

16. Poth, U. Automotive Coatings Formulation, May 2008 ISBN: 9783866309043.

17. Schulz, U. Accelerated Testing, November 2008, ISBN: 978386630908.

18. Poth, U.; Schwalm, R.; Schwartz, M. Acrylic Resins, published August 2011, ISBN: 9783866308572.

19. Gysau, D. Fillers for Paints, published March 2011, ISBN: 9783866308701.

20. Sander, J. Anticorrosive Coatings, published July 2010 ISBN: 9783866309111.

21. Mischke, P. Film Formation in Modern Paints, published December 2009 ISBN: 9783866308619.

22. Oyarzún, J.M. Pigment Processing, published May 2000, ISBN: 9783878705567.

23. Dietrich, R. Paint Analysis , published August 2009, ISBN: 9783866309128.

24. Bhushan Bh. (Ed.). Springer Handbook of Nanotechnology., 2nd revised and extended edition. Springer Science + Business Media, Inc. Berlin, Heidelberg, New York 2007.

Report Abusive Comment