Material safety data sheet (MSDS) to safety data sheet (SDS) conversion will be a very real part of the business plan for coatings manufacturers in the upcoming year. The June 1, 2015 deadline is less than a year away, and every hazardous chemical that a company uses must be classified, relabeled and given a new safety data sheet to match the Globally Harmonized System for Classification and Labeling of Chemicals (GHS).

In addition to modifications in classification and labeling, converting from the MSDS format to the new GHS-based SDS format requires new pictograms, terminology and 16 sections calling for specific chemical information.

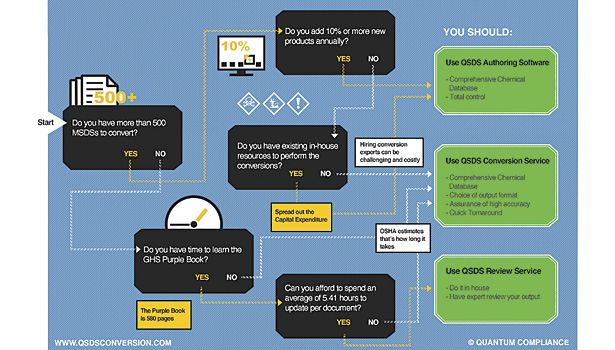

Knowing the assignment and the acronyms associated is the first step. It’s also essential to know about the meaning and procedure of MSDS to GHS SDS conversion. Because the process is, by necessity, an expensive and time-consuming one, it’s important to take some time to develop a plan to become GHS compliant.

What Is GHS?

Let’s start with the basics. In 2013, the United Nations issued the fifth revision to its Globally Harmonized System for Classification and Labeling of Chemicals, which mandated new formats and hazard classification standards for all hazardous chemicals. The GHS, also referred to as the Purple Book, made four main changes to MSDS regulations: 1) MSDSs will be renamed SDSs, 2) those SDSs will have 16 required sections with specific information listed under each, 3) new labeling practices will have to be followed, and 4) updated employee training rules will have to be implemented.

Theoretically, as of December 1, 2013, employees should have been fully trained in understanding and carrying out business according to GHS hazard pictograms and warning statements. This part of the GHS hopefully already has been covered within your own doors, so we do not need to go into it here, although it is an important task that is heavily related to the conversion process.

GHS Is More Than Just a Format Change

Before employees can begin to apply the skills they learned from their GHS safety training program, it is important to create new SDSs and GHS hazard labels for use. Some companies don’t realize the significance of the MSDS to SDS conversion undertaking, and believe they can hold off on making this change until much closer to the deadline.

Many, seeing this format shift, believe all that is needed to meet GHS standards is to reorganize their data so that it fits neatly into those categories. However, this is an important point that many companies overlook, so it bears repeating: GHS conversion is much more than just a format change. The processes of properly classifying each chemical’s hazards and reporting the relevant information are elements of the GHS that are crucial for compliance and for the safety of employees and customers.

The classification process is fairly complex; therefore, those companies interested in doing conversion in-house will likely have to spend a lot of time learning the methods of classification and deriving all pertinent information.

Partnering With a GHS Conversion Provider

The best option for companies that opt to forgo the many challenges of in-house conversion is to use a GHS conversion service. Conversion services have many benefits: they are less expensive than software, offer full support throughout the process, and the tedious work is avoided.

There are two main variations within the realm of GHS compliance services. Some companies provide “co-authoring” services, in which you enter all of the information from your MSDSs and the company then produces the finished SDSs. This service, however, requires a lot of work from your end, often without enough of a price reduction from full conversion services to make it worthwhile.

The more effective and streamlined conversion service is full MSDS to SDS conversion. In this process, companies only need to provide a current MSDS and possibly a small amount of extra information.

Labelmaster, for example, has partnered with Quantum to offer a full-service MSDS to SDS conversion service to help businesses comply quickly, easily and hassle-free with the new GHS, removing the time-consuming burden from coatings manufacturers’ internal staff. The process includes reviewing current MSDS sheets and providing conversion options to ensure the new SDS form is correct. The system handles the entire process, from reviewing documents all the way to compliant labeling of containers for downstream use.

How Does the Conversion Process Work?

The GHS conversion company will ask for your current MSDSs and, if not given on the sheets, your formulas and all pertinent Section 1 contact and naming information. Some companies may balk at the prospect of sending their formulas to a second company – after all, formulas are the basis of your business and you cannot afford to have them given to an insecure party. Hopefully, you’ll have chosen a company with years of experience and proven reliability that can be trusted with your information.

Consider having a conversation with the company at this point about what formats and languages you would like your SDSs produced. There will be extra charges for each additional language and format, no matter what company you use, so it is important to get a quote on these up front as well.

After you complete this process, it’s time to wait on conversion. Some companies will do a sample conversion ahead of time, so you can see if you like their process and product, and working with them in general. Take advantage of this opportunity because some companies will offer the sample as a discount, creating a low-risk trial run.

The sample conversion will give you a good idea of how the provider works and what to expect from them with the rest of your MSDS conversions. In addition, any company with good customer service should provide turnaround times so you have a precise idea of when you can expect to have your MSDSs.

Another important aspect of MSDS to SDS service comes after the conversion – the review process. A reasonable company will convert your MSDSs in batches, so you can look at the first 30 or so SDSs and determine if there is anything in the sheets you would like fixed. This approach is preferred to waiting until all your safety data sheets are complete and having to redo hundreds of them.

If your MSDSs are being translated into a different language, the company should also send some samples so that you can make sure you like the content before translation, since the translation process is quite expensive.

The last part of the conversion process is delivery. Many companies have a website where they upload your completed SDSs for your downloading in real-time. Some companies will charge extra if you request both PDF and Word delivery, others will not. At this point, you will be informed and your SDSs can be downloaded in full.

Tips for Selecting a GHS Service Provider

Experience is the most important factor to look for in a conversion company. Some companies started up simply to capitalize on the need for GHS compliance, with no prior environmental health and safety (EH&S) experience. It is important to identify a company that understands how safety procedures work and understands the chemicals involved. Doing so will give you more reliable output when it comes to matters as important as the intricacies of GHS hazard classification.

You also should review a company’s prices to make sure they don’t have hidden charges. Some companies even promise that they don’t have extra conversion fees beyond the quoted price, but later charge for services like consultations and document analysis. It’s essential to partner with a company that provides full disclosure on price up-front.

Also be sure to check that the vendor offers excellent customer service. Are you regularly put on hold at a company? Do they respond to emails in a timely fashion? Do they follow up on calls? Are you informed about delays or do you find yourself waiting? With a matter as time-sensitive as GHS compliance, it’s important to have attentive and efficient service.

Overall, for a less-stressful experience, start early. Service providers will be extremely busy in the months leading up to the June 1, 2015 deadline and may not even be able to accommodate your conversion. Getting started on converting your MSDSs to GHS SDSs as soon as possible and using a conversion service to do so are guaranteed ways to make your transition as smooth as possible.

For more information, visit www.labelmaster.com.

Report Abusive Comment