- Efficient

Enabling

Economical

Energy saving

Enviro-friendly.

The conference program began with a full-day meeting of the UV/EB University. The university's topics were "Design of Experiments for UV/EB Scientists and Engineers," Polymer Chemistry for the UV/EB Professional Short Course - Undergraduate Course," "Fundamentals of Photopolymerization Short Course - Graduate Course," and a free "UV/EB Primer Session." The courses, for which there was a fee except as indicated, gave conference attendees an opportunity to obtain an in-depth understanding of practical photochemistry. Each course ran from 9:00 a.m. to 5:00 p.m., so attendees had to select between the courses and choose the one most appropriate for their needs. Those taking the ‘design' or the ‘fundamentals' courses received Continuing Education Credits.

Within the technical conference, 97 speakers in as many presentations dealt with many aspects of radiation-curing technology. Major topic areas, with the number of papers in the area given in parenthesis, were Adhesives (6), Cationic Chemistry (8), Chemistry - two sessions (13), Equipment (8), Formulation of Coatings - two sessions (11), Graphic Arts Specialty Applications (6), Industrial Specialty Applications (4), International Market Review - China, Europe, United States (3), Measurement and Analysis - two sessions (10), Nanotechnology (7), Photoinitiators - two sessions (11), Raw Materials (6), and Waterborne (4). Interest was high in these topics and, even though the meeting rooms were large, there was standing-room-only available in many sessions. Overall, the individual sessions were on time, and meeting rooms were sufficiently close in proximity that one could easily go from room-to-room to hear presentations of particular interest.

One-hour poster sessions on two of the conference days provided an opportunity for attendees to meet and visit with a number of the authors at the conference. The 18 poster presentations covered topics that included oxygen inhibition, determination of degree of cure, conformal coatings, performance of lamination adhesives, thiolene systems, as well as many more interesting items.

Lijing Gou and Alec Scranton from the University of Iowa received honors for "Best Paper", and Todd Roper of the University of Southern Mississippi won the Best Student Paper award. RadTech, for the first time, presented awards for emerging technology that included Boeing Co. for a new UV "paint-on-the-line" application that avoids removing large aircraft sub-assemblies from a production line; Sony Chemicals Corp. of America for UV-cured bar-code labels that allow labeling of parts that are to be placed in hostile environments as, for example, motor-vehicle engine compartments; Stuart Dean Co. for the use of UV to rapidly renovate hotel vanities and other surfaces; and Stratus Boats for their novel application in UV-cured composites that reduce the use of hazardous compounds as well as reduce record keeping, compliance, and reporting costs.

This helpfulness by suppliers seemed to be prevalent as one visited many of the booths in the exhibition area. Some raw material suppliers were partially formulating products to aid formulators and/or end users so that they would only need to fine-tune with additives or other ingredients to have a fully formulated product. During "breaks" in the technical presentations, the booths were very busy, and, although they were staffed by a number of employees, one often had to wait to speak with a company representative. Many suppliers said that product interest was high and that business was very good, which bodes well for the radiation-curing industry.

This helpfulness by suppliers seemed to be prevalent as one visited many of the booths in the exhibition area. Some raw material suppliers were partially formulating products to aid formulators and/or end users so that they would only need to fine-tune with additives or other ingredients to have a fully formulated product. During "breaks" in the technical presentations, the booths were very busy, and, although they were staffed by a number of employees, one often had to wait to speak with a company representative. Many suppliers said that product interest was high and that business was very good, which bodes well for the radiation-curing industry.

Of course, the "old standby" companies such as Sartomer Co., Surface Specialties UCB, Cognis Corp., Dow Chemical, Penn Color and others on the raw material side; Fusion Systems, Nordson, IST America Corp., Hanovia, International Light, Lesco, ITW Ransburg, and others on the equipment side; Ashland Chemical, BASF Corp., Red Spot Paint & Varnish Co., R & D Coatings, Inc., Sun Chemical Corp., and others on the formulated product side were there. The list could go on and on with the names of quality suppliers. Although "old standbys," these companies also had new products as, for example, Cognis had a variety of new oligomeric products such as alkylene oxide-capped oligomers of hydroxyethyl acrylate for free-radical cure. BASF introduced a curing system in which a carbon dioxide atmosphere is used for rapid cure of three-dimensional articles at low radiation dosage. Dow Chemical had a new ether-joined dicycloaliphatic epoxide for cationic cure. King Industries had new amide-based monomers and super catalysts for dual-cure of cationic systems in shadowed areas and in thick sections.

At the 2002 RadTech meeting, Ashland Specialty Chemical won the Best Technical Paper award with photocurable systems that would cure without added photoinitiator - i.e., their polyacrylate oligomers were self-initiating when exposed to ultraviolet radiation. This year they were offering these oligomeric products for sale under the FlexCure™ tradename. Within the oligomeric acrylate chain, there are highly reactive, photo-labile chromophores at alpha-carbon sites. When exposed to ultraviolet radiation, these sites yield free radicals that initiate polymerization of acrylates and other ethylenically unsaturated compounds. (See PCI, July 2004 for more technical information on these products.)

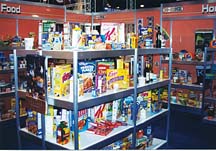

A feature of the exhibit portion of the conference was a "Techcell and Product Showcase" that vividly pointed out the many ways in which radiation-cured products touch our lives. Included in this showcase were, the Super-Store that showcased many of the retail products - dry cereals, household products, yogurt containers, pharmaceuticals, cosmetics, etc.- that we may see every day and are packaged with radiation-cured products; an Automotive Dealership that displayed radiation-cured parts and a demonstration of ultraviolet radiation-cured refinishing; and a House that UV/EB Built with various wood-finishing applications - cabinetry, doors and windows, flooring and molding, furniture, as well as specialty applications were shown. Within the Techcell, there were demonstrations and educational items that dealt with adhesives, plastics, UV measurement and UV-cured inkjet materials. Free CDs describing certain aspects of radiation curing were available to attendees.

The next major RadTech meeting in the United States will be held on May 8-10, 2006, in Chicago, IL. Details can be found on www.radtech.org.

Report Abusive Comment