MUNICH — WACKER Group announced that it has started to build a liquid resins unit at its site in Nünchritz, Germany. The unit will supply key upstream products for formulating silicone-based building-protection agents and binders for exterior paints and industrial coatings. Currently, only WACKER’s site in Burghausen, Germany, produces these substances. Scheduled to go on stream at the end of 2022, the new unit will close important material loops and further increase the cost-effectiveness of WACKER’s integrated production system. The company reports that capital spending will be approximately €30 million.

WACKER uses silanes and liquid resins to formulate several specialty silicone grades. Building-protection agents and concrete-protection creams contain these kinds of hydrophobic and hence water-repellent active ingredients, as do binders for exterior paints, corrosion-resistant protective coatings and heat-resistant powder paints. The company currently produces these additives at its liquid resins plant in Burghausen, where side-stream products resulting from the manufacture of silicones react with alcohol to become silanes and liquid resins. The company’s Burghausen and Nünchritz sites process these substances into silicone products for construction and coating applications.

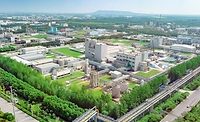

The foundations for a new liquid resins unit are now being laid in the northern part of the site. The unit will be able to process products obtained from the synthesis of methylchlorosilanes. “The decision to extend the production of silanes and liquid resins to Nünchritz enables us to respond with even greater flexibility to customer needs,” said WACKER’s Executive board member Auguste Willems.

The investment benefits both the Nünchritz site and the integrated production system in Burghausen. Due to high demand for building-protection agents and coatings, the liquid resins plant in Burghausen has been running at full capacity. “The new unit in Nünchritz closes material loops and increases the availability of key intermediates. This enhances our supply security throughout our integrated production system,” explained Willems. “The new setup offers us far more opportunities for supporting current market developments and for establishing production lines for new products if justified by demand.”

Learn more at www.wacker.com.

Report Abusive Comment