Bio-Succinic Acid in Coatings and Resins

Modern coatings continue to meet the basic aesthetic requirements and increased resistance to external influences demanded by the customer. However, as reserves of fossil fuels decline, the coatings industry must look to the future -despite today’s competitive oil prices -and aim to avoid raw material shortages.

The coatings industry as a whole has been through difficult economic times in recent years due to higher raw material prices, limited supplies and a decrease in consumer spending. To stay competitive, investments are being made in innovation and new technologies. Being responsive to increasing environmental pressures and regulation is also crucial.

Increasingly, government and industry regulations are driving the reduction of volatile organic compounds (VOCs) in resins. These same regulators are also calling for the creation of more sustainable resin products. The use of bio-succinic acid can increase the bio-based content of resins, such as polyester, alkyd and urethanes, while VOC levels can be further reduced by using solvents or coalescing agents based on bio-succinic acid.

Biosuccinium™ is a 100% bio-succinic acid that is made using a patented and energy-efficient low-pH yeast fermentation process. It has the best-in-class carbon footprint since it uses non-fossil raw materials and sequesters CO2, while also producing no waste salts.

Biosuccinium is a versatile C4 (4-carbon) dicarboxylic acid and has applications in a wide range of markets. It is offered as a bio-based alternative to oil-based succinic acid and as a near drop-in for adipic acid and phthalic anhydride for applications including coatings and resins.

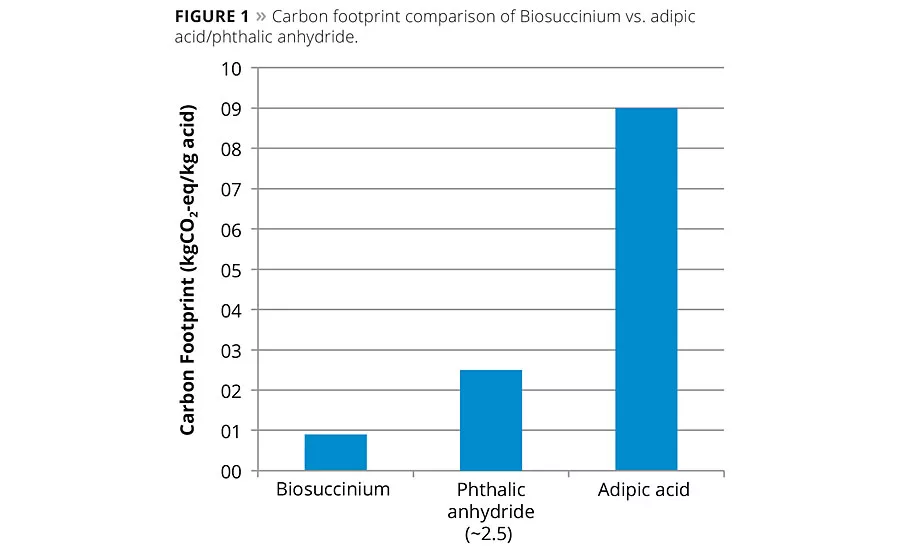

Generally, when non-renewable resources are substituted with sustainably sourced bio-based raw materials, the carbon footprint of the finished product is reduced and the renewable content increases. For example, compared to petro-based adipic acid or phthalic anhydride, the carbon footprint of Biosuccinium is lower by 90% and 50%, respectively (Table 1 and Figure 1).

For the final resin, the increase of renewable content and the reduction in carbon footprint obviously depends on the fraction of bio-succinic acid incorporated. In many cases, bio-based contents of 20-50% can be achieved. In conjunction with other bio-based monomers, the composition could result in 100% bio-based resins with a further reduced carbon footprint.

Application Benefits

While the initial steps of incorporating more sustainable elements into coatings have already been taken, being bio-based is not always enough to justify additional costs for raw materials, reformulation (if needed) and/or approvals. However, when new coatings applications based on renewable materials also include value-added performance advantages, this will significantly change the game and speed up market introduction. Indeed, in many cases, Biosuccinium-based coatings offer differentiated properties over current formulations.

Given the large variety of coatings and chemicals available today, and the broad application potential of succinic acid, it is very difficult to make generalized statements about the effects on performance and processing. However, following are clear examples of the application benefits that bio-succinic acid offers different coatings and resins.

Alkyd Resins

Vegetable oils or fatty acids are already in use as renewable raw materials for alkyd preparation. Bio-based alkyds with increased renewable content have now been commercialized. This was difficult to achieve as the other raw materials used in alkyds were typically derived from mineral oil and natural gas. With recent developments in bio-based chemicals and solvents, more and more options have become available to enable alkyd resins with increased bio-based content.

For example, alkyd resins have been made with almost 100% bio-based content, while simultaneously reducing the carbon footprint by 50%.1 This was done by using bio-based pentaerythritol and/or isosorbide and replacing petro-based polyacids with bio-succinic acid and other bio-based monomers, such as 2,5-furandicarboxylic acid (FDCA). The resulting alkyd coating showed increased hardness (Table 2).

A study comparing succinic-based and adipic-based resins found that saturated polyester resins from succinic acid had a higher glass transition temperature and a slightly higher viscosity. The resulting coatings were harder and more gouge-resistant.2 The gloss and clarity of the succinate coatings were equal to the adipate-based comparison reference.

Powder Coating Resins

Bio-succinic acid can also enhance the functionality of powder coating resins.3 In combination with other renewable monomers, such as isosorbide, 2,3-butanediol, 1,3-propanediol and/or citric acid, bio-based co- and terpolyesters were produced that outperformed petro-based alternatives.

The performance benefits included solvent resistance, impact resistance and hardness. Another study4 analyzed powder coating resins using succinic acid, isosorbide and recycled PET and found application performance that is similar in general properties, but superior for specific properties such as resistance to blooming and ageing, which opens up new application areas.

UV-Curable Acrylates

Bio-succinic acid is also used in the synthesis of UV-curable acrylates with commercially available bio-based monomers and oil-based acrylic acid (Table 3).5 An oligomeric polyester acrylate made based on bio-pentaerythritol and 12% bio-succinic acid has excellent chemical resistance and increased hardness. The bio-based carbon content is 44%.

When making a reactive diluent with 25% bio-succinic acid and 1,3-propanediol, this diluent has a bio-based carbon content as high as 63%. This can be used to modify the viscosity characteristics of UV-curable formulations while maintaining good film properties. The diluent can also bring the bio-based carbon content of the formulated coating to an even higher level.

Polyester Polyols and Polyurethanes

Bio-succinic acid also enables polyester polyol (PESPs) and polyurethane products to be produced with substantially lower carbon footprints. It is a potential alternative to petro-based adipic acid, which is commonly used as a raw material for PESPs and polyurethane-based coatings.

By using bio-succinic acid with bio-based diols such as 1,3-propanediol or 1,4-butanediol, it is possible to synthesize PESPs with a renewable content of up to 100% by mass. These were successfully used in the synthesis of polyurethane dispersions for textile coatings. Research by Bayer MaterialScience6 showed that amorphous polyols based on bio-succinic acid 1,4-butanediol and neopentyl glycol bring excellent performance to waterborne artificial leather.

In a similar way, bio-succinic acid will be a valuable raw material increasing the formulation flexibility for polyurethane dispersions to be used on other substrates such as wood, metal and plastics.

Other Possibilities

The next priority for more sustainable alkyds should be to substitute petro-based chemical solvents with bio-based solvents and to emulsify the alkyd in water with bio-based surfactants. Initial work has been done on coatings formulated with dimethyl succinate (DMS) as a solvent. Surprisingly, additional beneficial effects were found including a 40% reduction in drying time and faster-developing hardness of the coating film.

Another important range of chemicals for coatings (besides resins) where bio-succinic acid can bring both technical and sustainability advantages are solvents, coalescing agents and, to some extent, pigments. Di-esters such as DMS and diethyl succinate are used as a solvent. DMS compares favorably to dibasic ester (DBE) solvents, which are by-products from the polyamide production process. These DMS-based solvents also outperform DBE when cleaning paint and grease.

Furthermore, dimethyl succinate has been used to replace the commonly used aliphatic mineral spirit D40 in solventborne alkyd paint formulations, leading to faster -drying times (Table 2).

Higher-molecular-weight di-esters, such as di-2ethyl-hexyl succinate, can be used as coalescing agents for waterborne systems. Comparative studies versus some industry standard products have shown improved performance, even at lower dosage.7

For both solvents and coalescing agents it is important that they carry no (unpleasant) odor. In a recent study, which Reverdia actively participated in, the odor and color characteristics of 25 bio-based solvents were evaluated alongside three fossil-based solvents and water. Five succinate di-esters of different molecular weight were evaluated and all scored very well (Table 4). For odor, diethylhexyl succinate (DEHS) was rated second best, only outperformed by regular ‘tap water’. The other four succinates also scored well, with odor intensity slightly increasing.

In addition, DMS is a raw material for a number of pigments, increasing renewable content up to 40% in the case of quinacridones. Pigments based on DMS are PV-19, PR-122 and PR-202 (color index numbers 73900, 73915 and 73907, respectively). Di-isopropyl succinate, another succinic acid ester, is also a basis for diketo-pyrrolo-pyrrole (DPP) pigments.

By conducting further research into bio-based chemicals from other renewable sources, such as cellulosic waste streams, wood pulping byproducts and waste from sugar and potato processing or even CO2 gas, microbial oil and algal oil, bio-based resins for alkyd and other types of high-quality coatings with even lower carbon footprints will soon become a commercial reality.

Transition to Bio-Based

The benefits of bio-succinic acid for the resins and coatings industry are clear. While the demand for traditional fossil-based succinic acid in coatings has been limited in the past, mainly due to limited availability and higher cost, the potential for bio-based succinic acid is much higher and will continue to develop. A steadily growing knowledge base has demonstrated that bio-succinic acid can replace traditional oil-based raw materials and even improve their performance.

Bio-succinic acid has been produced for several years, and Biosuccinium has been tested and validated in various applications by numerous customers. The best-in-class bio-succinic acid (Figure 2) enables production of more sustainable materials and products in many markets.

With oil prices dropping, the bio-based coatings industry must strive to be competitive on integral system costs and has to provide enhanced performance to compete with petro-based alternatives. As already demonstrated, this has its challenges but can be achieved through a focused value chain approach taking in the whole industry.

In the Netherlands, the Association of Paint & Printing Ink Manufacturers (VVVF) initiated its Roadmap for Bio-based Coatings in 2011. The ambitious project aims for 50% of paints on the Dutch market to be based on bio-based raw materials by 2030.

The Roadmap, which was prepared with TNO, the Netherlands Organization for Applied Scientific Research, involves the whole value chain including raw materials, resins and paints. VVVF is committed to shifting towards higher bio-based content, and Reverdia has been involved in this project since 2014.

A survey of VVVF’s members, including Reverdia, has recently been conducted to provide yet more clarity on the current obstacles and bottlenecks for the uptake of bio-based coatings. The results of this survey will be announced in Q3 2015.

Conclusion

Industry leadership is crucial for bio-based chemicals to be able to compete with oil-based alternatives. Bio-based chemicals must compete on price and provide enhanced product specifications as well as deliver sustainability advantages. Many materials derived from bio-succinic acid equal or outperform petro-based equivalents, and with further incentives and industry buy-in, bio-based materials will continue to have a significant impact on the market for years to come.

Bio-succinic acid improves the quality of resins and coatings with value-added application benefits. It is also a more sustainable alternative than traditional oil-based materials. With ongoing projects, such as the Roadmap for Bio-based Coatings and other partnerships that facilitate knowledge transfer, the future for bio-based coatings and resins is full of opportunity.

For more information, contact Lawrence Theunissen at lawrence.theunissen@reverdia.com, or visit www.reverdia.com.

References

1Mestach, D. Sustainable Binders for the Paint Industry, Seminar on Green & Bio-based Paints, Nieuwegein, Netherlands, May 28, 2013.

2Guillaudeu, S.; Sonnenschein, M.; Wendt, B.; Argyropoulos, J.; Uzun, O. Materials from Succinic Acid – A Renewable Resource, ANTEC, Society of Plastics Engineers, 2011.

3Noordover, B.A.J.; van Staalduinen, V.G.; Duchateau, R.; Koning, C.E.; van Benthem, R.A.T.M.; Mak, M.; Heise, A.; Frissen, A.E.; van Haveren, J. Biomacromolecules2006, 7(12), 3407.

4Gioia, C.; Vannini, M.; Marchese, P.; Minesso, A.; Cavalieri, R.; Colonna, M.; Celli, A. Sustainable Polyesters for Powder Coating Applications From Recycled PET, Isosorbide and Succinic Acid, Green Chem, 2013, DOI: 10.1039/C3GC42122H.

5Davies, P.; Groen, H. UV-Curable Resins Based on Biosuccinium™, DSM Coating Resins, Internal Report, September 2013.

6Grablowitz, H.G. Sustainable Solutions with Bio-based PU Dispersions, European Coatings Congress, Nürnberg, March 2013.

7 Miryfilm Zero-VOC Coalescing Solvent Technical Bulletin, pages 3-5, 2014.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!