Providing the Best VOC Control Technologies

for Maximum Customer Value

RTO for treatment of emissions from fastener coating operation.

VOCs are captured by ducting of emission sources to RTO for treatment.

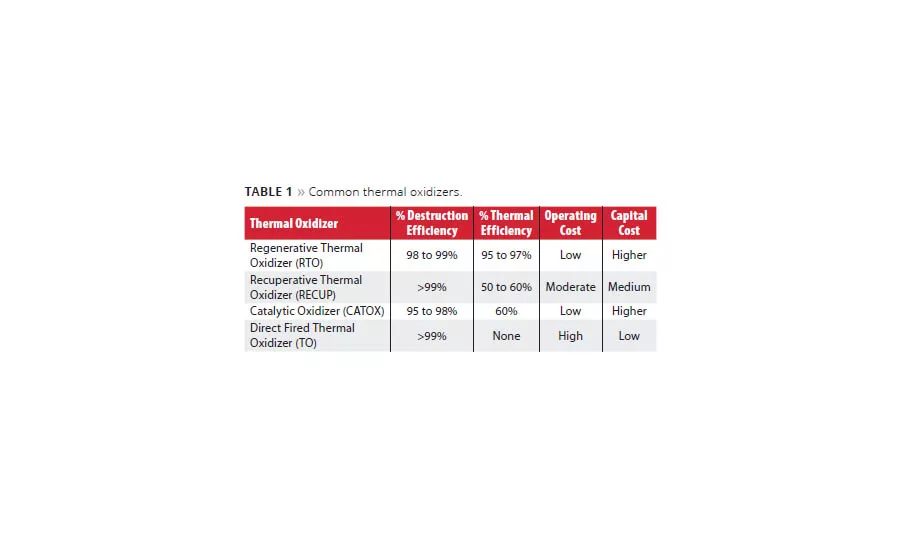

TABLE 1 » Common thermal oxidizers.

Consumer and industrial market applications are constantly challenging paint finishing operations with coating specifications that provide high-quality, durable finishes to meet customer expectations. The finishing industry is also challenged to deliver these finishes in an environmentally friendly fashion to minimize impacts to local surroundings and the air we breathe.

Volatile organic compounds (VOCs), Hazardous Air Pollutants (HAPs) and odorous emissions are emitted from a variety of manufacturing operations, including the paint finishing process. Each constituent used in a manufacturing process needs to be carefully considered, as some may present an immediate health hazard to employees as well as the surrounding community. The severity is dependent upon the specific constituent and total emissions per day, week or year.

VOCs emitted into the atmosphere become smog and will be pushed around by air currents just like emissions from transportation. Water-soluble VOCs will eventually end up in lakes, streams, rivers and oceans. VOCs are typically heavier than air and will build up inside a manufacturing environment as well. Fugitive VOC emissions within a building often collect in pockets on the floor and may present a potential fire hazard. Monitoring equipment may be necessary to prevent exposure beyond OSHA rules and to keep levels below the lower explosive limit (LEL). Nonsoluble VOCs that are collected at the source of emission are often treated by thermal oxidation or catalytic oxidation, depending on the VOC.

VOCs are regulated by federal, state and local regulatory authorities by guidelines established through the New Clean Air Act passed in 1990 and modified throughout the years. In general, these regulations limit the amount of VOCs or solvent emissions that can be emitted by a coating operation as a single solvent or as a solvent mixture. These are generally quantified in tons of emissions (allowable) and can differ across industries and locations.

There are various coating technologies that utilize solvent-, water- and powder-based materials, but solvent-based paint and coating operations are traditionally targeted for VOC abatement. However, keep in mind that water-based materials do contain small amounts of solvent. High-usage operations could eclipse threshold limits established by law and thus trigger the need for VOC control equipment.

The goal of any well-designed air pollution control system is to minimize the impact of coating emissions from the manufacturing process in a cost-effective way to meet regulatory requirements. Solvent emissions are emitted to atmosphere in a variety of ways from painting processes:

- At the paint application site – coating line or spray booth exhaust;

- In quiet (low air movement) flash-off areas;

- Curing or bake oven exhaust (majority of emissions found here);

- Paint storage areas;

- Paint mix areas.

Our goal is to select the best control technology that provides top value, while maximizing the overall destruction efficiency of equipment.

There are a variety of technologies that can be used - thermal oxidizers are the most prevalent. To ensure high destruction efficiencies a thermal oxidizer must be designed with proper residence time, temperature and turbulence. The thermal oxidation process results in an exothermic reaction releasing heat and converting the VOCs’ molecular bonds to CO2 and H2O. Most thermal oxidizers operate between 1400 °F and 1500 °F. For certain halogenated hydrocarbon VOCs temperatures between 1600 °F to 1800 °F are required to break the molecular bonds. Some carbon, hydrogen and oxygen bonds of VOCs may be broken by thermal oxidation at temperatures between 1100 °F to 1200 °F. But, high carbon monoxide (CO) will result at these temperatures. To convert the CO to CO2 requires higher temperatures. That is why most air quality permits require thermal oxidizers to operate above 1400 °F.

Thermal oxidizers come in a variety of arrangements that have a subtle effect on destruction efficiency, operating costs and thermal efficiency (the amount of energy that can be recovered from the combustion process). The most common thermal oxidizers can be seen in Table 1.

In general, all of the technologies perform well to meet most regulatory requirements. But, from this point, there are different qualities that make or break the use of the technology.

Equipment Summaries

Direct Fired Thermal Oxidizers (TO) can achieve very high destruction efficiency (+99%) at very low cost to install. However, TOs can be quite expensive to operate unless there is a tremendous amount of solvent in the exhaust stream that is being treated. The BTU value from the solvent load can supplement the burner operation, reducing the amount of natural gas utilized, but in general this is a very expensive technology to operate.

Catalytic Oxidizer Technology (CATOX) can achieve generally up to 98% destruction efficiency. CATOX technology uses heat and catalyst technology (precious metal) to destroy VOCs at a lower operating temperature (600 to 800 °F) for minimum energy usage. However, catalytic oxidation is suitable for treatment of only certain VOCs. Additionally, catalysts can be prone to contamination by particulates (phosphorus, silicon and halogens), reducing or eliminating the effectiveness of the catalytic oxidizer. Using a catalytic oxidizer may reduce operating costs due to the lower operating temperatures; however, catalyst replacement is extremely expensive and must be selected carefully. Catalysts only recover up to 60% of energy in the combustion process through an integrated heat exchanger unit. Cost is considered high to install.

Recuperative Thermal Oxidizers (RECUP) – similar to TOs – can achieve +99% destruction efficiency. RECUPs typically recover up to 60% energy expended in the operation of the unit via an integrated heat exchanger. Higher heat exchanger efficiencies require substantial higher cost. Cost is considered lower to install. Based on solvent concentration available in the exhaust stream, operation can be expensive.

Regenerative Thermal Oxidizers (RTO) feature destruction efficiency to 99% and thermal efficiency to 97%. RTOs tend to exhibit the most flexibility in a variety of applications due to their excellent destruction and thermal efficiency properties. RTOs tend to be popular because they can effectively control very low solvent concentrations cost effectively, due to built-in heat recovery (most efficient technology), and, in turn, have high destruction capabilities. The downside to RTO technology is that it tends to be the most expensive to install. But, these capital costs can be offset over a shorter period of time with lower operating costs (lowest natural gas consumption).

Adding Value to an Air Pollution Abatement System

The key to a successful air pollution abatement equipment implementation project starts with a review of relevant parameters by experienced engineers with expertise in the type of manufacturing process requiring the abatement system, and the ability of the supplier to understand the unique goals and objectives of the application.

The decision to control VOC emissions with a thermal oxidizer from your manufacturing process, whether mandated by regulation or voluntarily, comes with a price. This is usually manifested in dollars and time across your organization – manpower, new equipment, added energy costs, regulatory permitting challenges, and facility design changes (concrete, ductwork, piping and wiring).

For maximum project value throughout the entire equipment selection process, several basic value-added benefits should not be overlooked for best project value. Understanding the paint process helps maximize abatement equipment potential. Suggestions include:

- Minimize air flow to the oxidizer while enhancing VOC capture (using air emissions as fuel) to the abatement unit.

- Work with environmental engineers and/or consultants to achieve regulatory compliance. Seek assistance in filing for air quality permits.

- Research possible secondary process heat recovery opportunities to maximize energy recovery for overall lower operating costs.

- Incorporate design provisions in the system anticipating future potential process changes.

- Develop knowledge, experience and relationships to take advantage of new construction incentive rebates available through natural gas and electric utility entities. These very lucrative returns are available primarily for highly energy-efficient equipment projects such as an RTO. There are possible six-figure rebates based on equipment sizing.

Managing the Process

Operation of a VOC control system is energy and capital intensive, but there are factors that offset these costs. VOC sources from within the plant can be handled in a way that minimizes total flow by adding permanent total enclosures, and or, recirculating a portion of the source stream back to the process. In this manner, incoming fresh air can be conditioned (in the case of dryer/oven exhaust, preheat incoming air saving initial dryer energy cost), and the amount of air that flows to the destruction device can be reduced (lower capital cost for smaller equipment). In addition, by recirculating solvent-laden air back to the process, VOCs or Btu value in the overall exhaust stream are increased, providing fuel to the destruction device (solvent air combusts in the thermal oxidizer, minimizing fuel needed for the oxidizer to maintain temperature). In certain instances, this recirculated air stream can provide enough fuel value for the pollution control device to operate without any primary natural gas or in pilot mode.

By reducing total air flow, the VOC control device can be downsized, resulting in lower capital cost. This can be accomplished by design of capture hoods, floor sweeps, enclosures, ducting and recirculation within the process generating emissions; resulting in a significant reduction in overall air flow requiring treatment and an increase in the overall solvent capture levels. Safe solvent levels within the process operation must always be considered and may require LEL monitoring. Additional benefits of a properly designed solvent capture system include: reduction of fugitive emissions, increased total VOC capture, increased total VOC destruction for the facility, reduced natural gas usage for the control device and reduced overall operating costs.

Tail Pipe Energy Recovery

“Tail Pipe” energy recovery is also possible. VOC control devices operate at very high temperatures (1500 °F typically). Although certain oxidizers can recover up to 97% of this heat (in the case of an RTO), there is enough remaining heat in the exhaust temperature to provide heat for secondary air/water sources needed within the plant or process. Secondary heat exchangers can provide fast payback to offset additional project costs. Additionally, many of these concepts qualify for utility provider incentive funding dollars.

Conclusion

By properly matching painting process applications to VOC control equipment options, overall capital investment and operating costs can be significantly reduced. Oxidizer systems must be reliable, durable, easy to maintain and operate. Companies can have tailor-made solutions to place them in a position of success by focusing on cost-effective solutions that provide long-term success and compliance with regulations. Better air quality, energy efficiency, maximum profitability and return on investment all allow companies to grow and expand their businesses through the addition of well-thought-out environmental controls.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!