In the world of organic red, pole position belongs to diketo-pyrrolo-pyrrole. Best known as DPP, it now commands the two coveted positions of yellow-shade and blue-shade reds in a way that phthalocyanine dominates the blues and benzimidazolone dominates the yellows.

But in terms of development, DPP has been a victim of its own success, performing so well that until now it has been held back for commercial reasons behind an illustrious line of predecessors: quinacridone, perylene and anthraquinone.

Swan is a new entrant to the colours sector, launching a major international business in 2004 to challenge the relatively narrow base of established big suppliers. The company already had a strong position in coatings technology and ink additives, but it is Swan’s pedigree of innovation that has led it to introduce disruptive technology into the colours market. It was voted a “Top 20 Innovator” by a major U.S. chemical publication and has been leading the way in certain nanotechnology applications and in supercritical-fluid chemical synthesis.

Not only is DPP synonymous with quality, it has a durability and performance to rival the phthalocyanines. It offers crystal-clear blends and a brightness not achievable with any combination of any of the other red pigments in its class. In short, it can offer the gamut of C.I. Red 112 all the way over to C.I. Violet 19 without once appearing dirty or under-strength. In real terms this is nothing short of amazing, as virtually every shade of red is covered and, with the DPP orange to complement the range, it can offer the formulator the widest palette of colours of any of the pigment chemistries.

Performance Enhancement

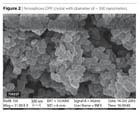

So what has Thomas Swan done to improve DPP? Figure 2 shows a typical amorphous DPP crystal with a diameter of approx 300 nanometers. One problem with this particular crystal morphology is that the colour strength cannot be increased without compromising the opacity; to put it another way, this offers the way to a strong, transparent pigment or a less strong opaque pigment.

Obviously there is a relationship between particle size and surface area; this manifests itself in the oil absorption of the particles, although this relationship is not entirely inversely proportional. The Thomas Swan DPP pigment does have a slightly higher varnish demand, but since the colour strength is so much higher it can replace amorphous DPP without any compromise in performance to give a brighter, stronger shade.

Styling

Combine the new transparent grades of Thomas Swan DPP Reds with metallic and pearlescent pigments and you open up a whole new world of clean, bright, sparkling shades for use in automotive coatings. They can be formulated into existing solventborne paint systems with ease. The new grades are also perfectly compatible with newly developed waterborne systems. Contact Thomas Swan’s experienced technical team for specific formulation guidelines or technical assistance.The styling options do not stop there, however, as DPP pigments can also be used for colouring the interior plastic and textile parts (including polyolefins, PVC and ABS), giving a complete range of interior and exterior colour options.

When using the newly developed Super Opaque DPP grades users will immediately notice the improved hiding power. The benefits are twofold: firstly, the amount of paint required to cover a panel is reduced and secondly, the superior hiding power allows the option for utilizing existing undercoats.

Another feature of DPP pigments is their heat resistance. They are perfectly stable at temperatures up to 300 ºC. The pigment allows colour styling improvements over inorganic pigments, while at the same time giving a huge increase in colour strength eliminating any toxic issues with heavy metal-based chemistries. One major advantage in this area is the FDA status of DPP red, which opens up styling options for cooking and baking utensils. Table 1 provides a summary of DPP red properties.

For further information, visitwww.thomas-swan.co.uk.

Report Abusive Comment