For the past several decades, the focus of interior latex paint performance has been on improved hiding power, scrub resistance and color acceptance properties. Driven by regulatory initiatives, new paint formulations are required to meet low-VOC regulations. These regulations have forced paint formulators to seek practical solutions to overcome additional challenges, such as poor wetting, flow, foaming, block resistance and stain resistance that result from the reduction in VOC content in paints. For flat to low-sheen eggshell paints, washability (or easy-clean) has become the most difficult property to achieve. Softer resins, lack of coalescent aids, longer film forming time, lower film forming temperatures, and overuse of surfactants and additives are contributing factors to poor washability. Easy-clean and stain resistance are not only highly desired by consumers, but these properties can also extend paint service life and reduce recoat cycles for environmental protection. These benefits provide long-term value to our society and future generations.

Stains that adhere to interior latex paint films are divided into two groups: hydrophilic and hydrophobic. Hydrophilic stains, often called common household stains, include soy sauce, tea, coffee, red wine, colored markers, etc. Hydrophobic stains mainly come from oily hands or fingerprints typically found around door frames and light switches. Other hydrophobic stains are crayons, pencils, or tomato sauce.

The washability of hydrophilic stains depends on the water resistance of the film. The most effective way to increase water resistance of the paint is to use higher water-resistant binders and a lower pigment volume concentration (PVC) ratio to form a compact film. The use of hydrophobic additives, such as silicone oils or waxes, can also boost hydrophilic stain washability. However, the latter approach can lead to poor oil resistance as well as surface defects, such as pinholes, craters and fisheyes.

Hydrophobic stain washability depends largely on additives if the binder type and PVC level are set. Fluorosurfactants (FS) have proven to be the only chemical in the additive class that can provide oil resistance through migration to the paint surface when the paint is wet, and cure into it when the paint is dry. Due to latex paint formulation complexity, simply adding a fluorosurfactant to the formulation is less effective than using it to optimize the total formulation.

Formulating a well-balanced easy-clean paint is never a simple job.1,2 Easy-clean performance is related to the overall formulation design, as well as the selection of the individual components. Binder type, PVC ratio and the additives package are considered as three key factors for easy-clean performance. Among them, the resin is the most dominant component. However, even with a few newly developed easy-clean targeted binder systems, the choice is still somewhat limited due to availability and cost.

The second most important factor to an easy-clean paint is its PVC ratio. Super-high PVC paints have a PVC ratio exceeding Critical PVC (CPVC), which means that it does not have a continuous film at the surface. Some interior paints have higher than 70% PVC. These paints are highly porous,3 and stains can easily penetrate into the pores. As a result, it is extremely difficult to wash off the stains. To achieve good easy-clean performance, it is necessary to have a continuous film at the surface. In other words, the PVC level of the paint should be controlled below CPVC. This PVC level control will help block initial stain penetration and maintain scrub resistance to sustain repeated washes in the stain removal process. Poor scrub resistance can be misleading for a superficial easy-clean paint. The truth is that the cleanability is due to the loss of surface film by abrasion. Common side effects are change of gloss level, loss of hiding and the need for touch-up or recoating.

The additive package also plays a very important role in easy-clean paint performance, especially with surfactants and defoamers. Optimized additive packages can deliver cost-effective solutions for the paint formulation. Hydrophobic additives, while effective against hydrophilic stains, have no positive impact on cleanability of hydrophobic stains. An oily-stain-resistant additive is needed to balance overall easy-clean performance of the paint.

Historically, fluorinated chemicals have been used as typical surface treatments for carpet, stone and textile surfaces to provide water and oil repellency.4,5 In our previous studies, we demonstrated that fluorosurfactants can be used as multi-functional additives to provide wetting, leveling, anti-blocking, and oil repellency in low-VOC latex architectural paints and water-based wood coatings.6,7 In this article we focus on the easy-clean property of paints. Three binders and two PVC levels were selected to evaluate the performance with the addition of two fluorosurfactants. The fluorosurfactants are commercially available products based on new short-chain fluorochemical technology with a superior performance and environmental profile. The basic chemical structure of these fluorosurfactants contains a non-polar fluorocarbon component and polar functionalities. Fluorosurfactants are surface active, and have a lock-in mechanism to ensure durable performance. Minor adjustments of hydrocarbon surfactants, defoamers and rheology modifiers were included in the formulation design.

Performance data of Leneta stain (representing oily stains), household stain cleanability, and water and oil contact angle are discussed in detail. We also selectively checked the impact of the fluorosurfactants on hiding power, gloss and scrub resistance. The study demonstrates that optimizing the paint formulation through the use of fluorosurfactants can improve latex paint easy-clean performance.

Experimental

Coating Formulation and Panel Preparation

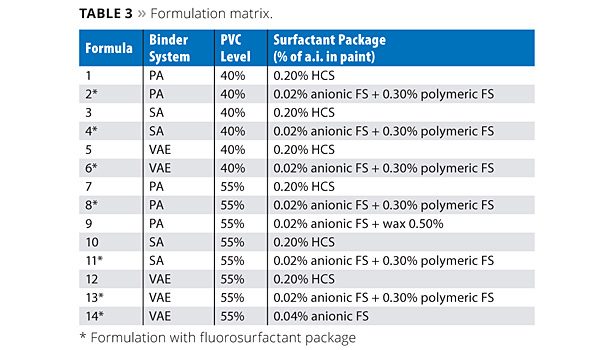

Three binders: styrene acrylic (SA), pure acrylic (PA) and ethylene vinyl acetate emulsion (VAE), and two PVC levels (40% and 55%) were used to design the base formulations. Two surfactant packages were selected to investigate easy-clean performance. One surfactant package contained a nonionic hydrocarbon surfactant (HCS), which was used as a pigment wetting agent in the grind stage. The second surfactant package contained an anionic fluorosurfactant (FS) added as a pigment wetting agent with reduced defoamer in the grind stage, and a polymeric fluorosurfactant added in the letdown stage as an easy-clean additive. Generic formulations for PVC 40% and 55% are listed in Tables 1 and 2. Fourteen paint formulations were made, and their formulation matrix by function is shown in Table 3.

Film Preparation

Formulated paints were mixed thoroughly and aged for 48 h to achieve maximum dispersion of the fluorosurfactant additives. Paint films were prepared on black Leneta Mylar® drawdown cards using a BYK-Gardner automatic drawdown machine and a bird applicator drawdown blade. The blade clearances were 5 mil for the cleanability test and 7 mil for the wet scrub test. The drawdown speed was 30 mm per second to produce even film thicknesses. The film was allowed to dry at room temperature for 7 days prior to evaluation.

Hiding Power and Gloss

The hiding power of paint measures its opacity or its ability to cover under-layer color so as to obscure or prevent the original color from showing through. Hiding power is determined by contrast ratio on standard black and white Leneta cards.

Contrast ratio=Rb/Rw

Rb: reflectance over black substrate

Rw: reflectance over white substrate

Contrast ratio and gloss of the panels were measured by a spectrocolorimeter supplied by Sheen.

Wet Scrub Test

Wet scrub resistance was tested per ASTM D2486 Method A. The dried panel was placed on the top of a shimmed plate in the Sheen wet abrasion scrub tester to start the test. The number of cycles, at which one continuous thin line of substrate was observed, was recorded.

Leneta Stain Cleanability

This test is a modified version of ASTM D3450. The prepared panels were cut into 40 x 100 mm sections for testing. The stain was applied to a Mylar card through a template with an 8 x 2 mm window to make a clear-edged staining area (Figure 1). The stain was allowed to remain on the panel for 1 h. The excess stain was gently scraped off and the stained areas were carefully wiped with a clean paper towel until no visible stain could be wiped off (Figure 2). The washing block of the abrasion tester was covered with eight layers of cheesecloth. Then 20 mL of cleaning solution (1% mild detergent solution) was added to the cheesecloth and the washability tester (Figure 3) was run for 25 cycles (50 wipes) over the stained drawdown panel. After rinsing with water and drying for 2 h, the panel was rated. Unstained paint, unwashed stained paint and washed stained paint were measured three times in different areas to report average L value by a colorimeter. Leneta stain cleanability rating can be calculated by the following formula:

(L washed paint – L unwashed stained paint) ×10 /

(L unstained paint – L unwashed stained paint)

Household Stain Cleanability

The household stain cleanability method measures the relative degree of common household stains removed by washing with a 1% mild detergent solution. Dried paint panels were divided into 20 mm width area for different stains. All stains were allowed to dry at room temperature for 1 h before washing. After the test, the panel was rinsed with water and dried for 2 h. Remaining stains were judged visually on a scale of zero to 10 to reflect 0% to 100% of stain removal.

Water and Oil Repellency

The water and oil contact angles of panels were measured with a Goniometer using a high-speed CCD camera for image capturing. Water or n-hexadecane (oil) was dropped onto the surface by a syringe. The computer-aided Goniometer software measures a droplet’s advancing contact angle by assuming the droplet fits the geometry of a sphere when the drop is stable after 1 min. A high water or oil contact angle indicates high hydrophobicity or oleophobicity of the coating.

Report Abusive Comment