In the February issue, I supplied some statistics on powder coating sales taken from the U.S. Census Bureau. A reader contacted us and pointed out that my numbers for the dollar value of powder sold were correct but the reported number of pounds of powder sold did not make sense. I checked to see what could be wrong and the numbers that I reported were exactly what the Census Bureau reported. The glitch was in the translation of units. The number reported was 73,946,000. I listed that as pounds. If you do the math you will find that the dollars listed do not divide out to any reasonable number so the unit of measurement is not correct. I then tried to convert the number using several common formulas for conversion from gallons to pounds to try to figure out what the Census Bureau was reporting. Alas, no conversion formula produced logical results. I also tried to contact the Bureau to see what the reported number actually measured but I was not able to get a timely reply. Finally, I turned to the Powder Coating Institute (PCI) to get some data to accurately report the real volume of powder sold in 2004 and a more accurate number on growth.

With 23 Member companies reporting, PCI reported sales volume of 314 million pounds with a dollar value of $775 million. The average cost per pound was therefore around $2.46/pound. Using that unit price per pound the estimated pounds sold by all companies (PCI Members and others) was around 337,063,414 pounds, not the reported 73,946,000. PCI reported growth for North American powder coating sales from 2003 to 2004 was 6.5 percent. Estimated growth by PCI for 2005 is around 5 percent.

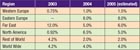

A look at the worldwide market shows that the trend in developing nations is for more growth with Eastern Europe and the Far East leading the way (see table).

Imports, raw material cost and downward pressure on pricing continue to challenge American powder manufacturers. Demand is still somewhat soft compared to the last two decades of powder usage in the United States.

One issue that challenges the powder market is the lack of understanding of the value of the product. Too many companies continue to dwell on unit price and regard powder coating material as a commodity that can be equally supplied by a number of manufacturers. The reality is that value can be built into a powder product to provide better application and recovery characteristics. It is often possible to apply a powder at thinner, more uniform film builds and possibly get better performance by purchasing a more expensive product. The real importance is in the applied cost per square foot, not the unit price.

We will continue to watch the market and report on the statistics for 2005 and 2006 as they become available. Thank you to Phil for pointing out the discrepancy.

Report Abusive Comment