Luminous Metal Effect Pigments

New pigment technology for automotive coatings

Color is said to be one of the most important differentiators for consumer purchases, especially as the value of that purchase increases. As more durable and brilliant varieties of pigmentation technology become available, they are incorporated into automotive styling. Included in this variety of pigmentation are effect pigments, which are a broad category of materials consisting of metallic effect and pearlescent pigments. These materials have some unique capabilities with respect to how they interact with light, specifically due to their architecture (typically a platelet structure with a high aspect ratio). Depending upon the specific technology, a wide variety of colors and effects can be created, such as interference shimmers, color travel effects or metallic reflection.

Pearlescent Pigments

Traditional pearlescent pigments consist of a high-refractive-index metal oxide layer coated onto a transparent, low-refractive-index substrate such as natural mica. This layering structure interacts with light to produce constructive and destructive interference patterns in both the reflected and transmitted light, which we see as color. This technology has been extended to other synthetic substrates such as glass, alumina, silica and synthetic mica. Various effects range from satin and pearl luster, to sparkle with high chromatic values, and hue-shifting color highlights, again depending upon the exact architecture (type of metal oxide, layer thickness, particle size distribution, aspect ratio of the substrates, etc.). When coated with titanium dioxide, these interference pigments range in color from silver, gold, red, blue and green. Additionally, iron oxide-coated substrates result in a deep chromatic luster effect. The main limitations of the pearl effects are lack of opacity and lower lightness contrast between specular and down flop angles.

Aluminum Metal Effect Pigments

Metallic effect pigments are typically aluminum flakes or metal oxide-coated aluminum flakes. Pure aluminum effects are characterized by high opacity, sparkle to satin finish and a high level of lightness with colorless spectral reflection and dark flop (diffuse, non-spectral reflection). In essence, they tend to act like miniature mirrors within the coating film, however there are variations in shape and particle size that characterize the differentiation in aluminum pigments. Cornflake types are irregular in shape (much like the cereal type from where it gets its name), whereas silver dollar types are rounded with smooth edges. VMP aluminum is a highly reflective specialty product produced by a vacuum metallization process. These variations in architecture lead to significant differences in performance, most notably in spectral lightness and flop behavior. In general, the flatter and smoother the pigment particles, the more spectral reflection and flop behavior are generated. The contrast in lightness with different viewing angles is highly desirable, but there are some limitations when used in high chromatic color systems.

Meoxal® Luminous Metal Effect Pigments

Technology

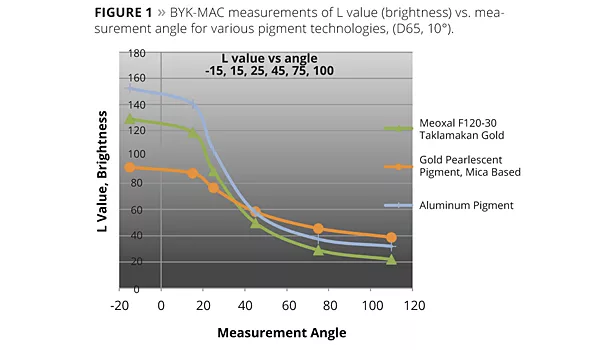

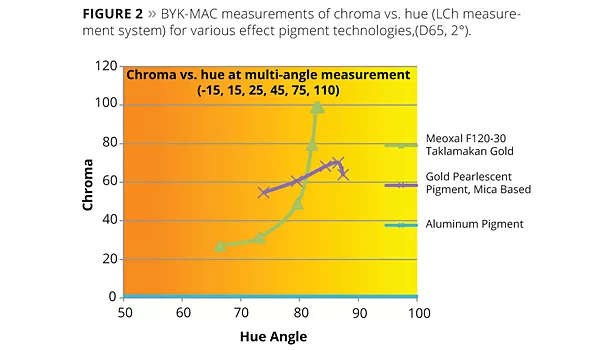

Each technology previously described has their own unique benefits and drawbacks, and combinations of these technologies are often used to optimize a color styling for an automotive coatings manufacturer. One of the newest technologies available on the market today are Meoxal effect pigments from EMD Chemicals (an affiliate of Merck KGaA, Darmstadt, Germany). This technology is rather unique because it combines several key properties from different effect pigment technologies (substrate layering with metal oxides, new flake technology, and innovative and patented intermediate layering) into a single package and yet also looks to increase the color space capability of any formulated styling in which it would be used. A representative comparison of these technologies with respect to color positioning can be found in Figures 1 and 2.

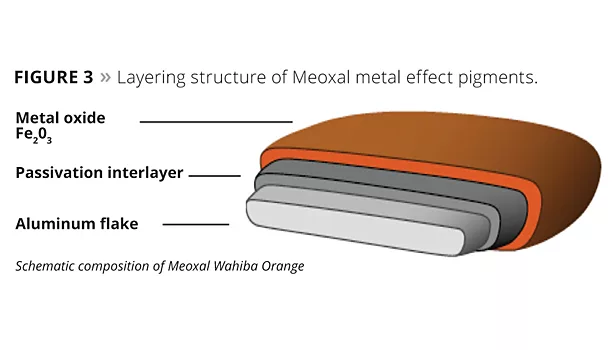

The Meoxal pigments are based on an aluminum silver dollar type substrate coated with a passivation interlayer, then coated with a metal oxide outer layer (Figure 3). The pigment is finally given a special surface treatment to increase its weathering durability and dispersed in a solvent chosen for optimum universal use (diethylene glycol ethyl ether). The solvent choice also provides decreased agglomeration tendencies in package storage, ease of use and removes the risk of dust explosion.

The passivation interlayer is a unique technology to EMD Chemicals, and allows for inclusion of these materials directly in waterborne systems without extra passivation steps that may be required with competitive technologies. Furthermore, Meoxal pigments can be used in both solventborne and waterborne systems, which eliminates the need for separate products for either formulation. By removing an extra step in the incorporation process, and creating a universal use product, formulating new color variants becomes easier.

Product Offerings and Application Properties

This type of pigment exhibits a striking brilliance at the specular angle, with a dramatic drop at diffuse angles. This property helps to accentuate the body lines on an automobile and add depth and differentiation to any coated substrate. The iron oxide layer renders Meoxal pigments with several variants in the warmer color space areas (gold and orange) with very strong chroma. The color spaces chosen for these materials will allow a wide variety of formulation options, particularly when used in combination with semi-transparent pearlescent pigments as well as transparent organic pigmentation, and covers the largest color space for this class of material on the market today.

Meoxal F120-58 CWT Wahiba Orange and

Meoxal F120-30 CWT Taklamakan Gold

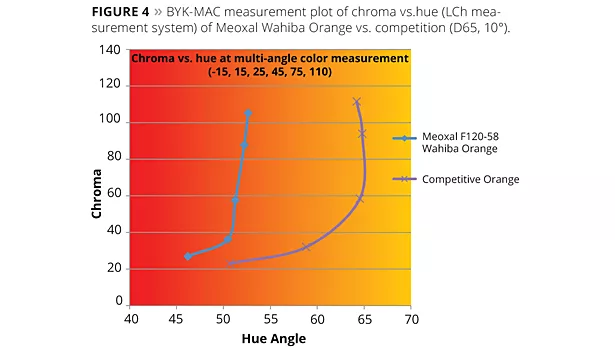

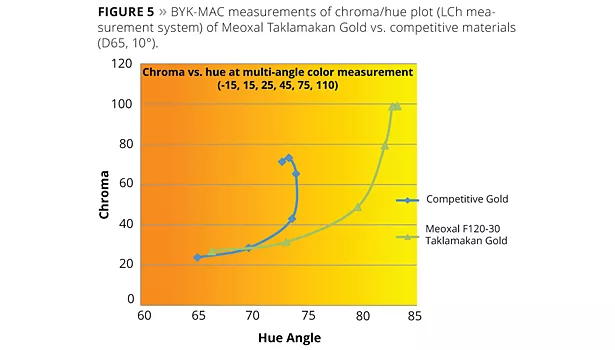

Meoxal Wahiba Orange and Taklamakan Gold (particle size: 5-30 µm) consist of iron oxide coated on passivated aluminum silver dollar flakes. Their high brilliance, outstanding color saturation and strong flop behavior (Figures 4 and 5) make them highly desirable for automotive coatings as well as high-performance waterborne coating systems. Meoxal Wahiba Orange shows a striking orange metallic look and occupies a unique color position relative to other aluminum-based pigments. It is particularly suitable for high-chroma stylings when warm colors (orange, scarlet, red, rubine and bordeaux) are sought. Meoxal Taklamakan Gold occupies a unique color space that will allow the formulator more latitude to travel from the orange range well into the green hues, and its strength of chroma is obviously advantageous to the degree that it allows combinations with other pigments to have access to a broader color space and offer gold hue or golden undertone in the shades of green, yellow, orange, red and brown/copper.

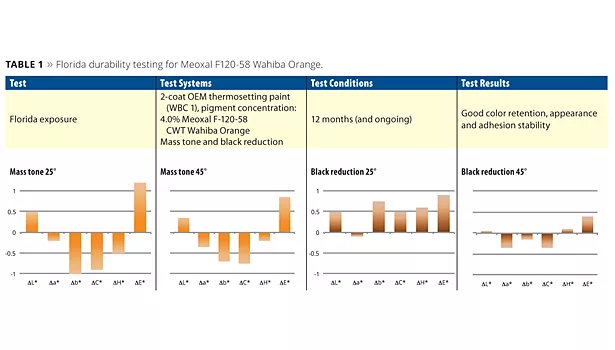

As most automotive coating applications are targeted for exterior use, it is important to note that Meoxal pigments have the capability to meet stringent requirements with respect to weatherability and application properties. Meoxal has undergone various durability and application tests and exhibits good storage stability, shelf life and durability for exterior applications. Tables 1 and 2 show the intermediate results of Florida durability testing with Meoxal F120-30 Taklamakan Gold and F120-58 Wahiba Orange.

Summary

The Meoxal luminous metal effect pigment line is the latest innovation in effect pigments from EMD Chemicals. Meoxal pigments utilize the strengths and advantages of pearlescent pigment technology combined with the highly desired properties of aluminum substrate, which is made possible by a patented passivation process. As a technology platform, the Meoxal line could be expanded to encompass a broader range of offerings designed to increase color space capabilities, as well as other aesthetic features inherent with this pigment technology. This unique technology will provide color stylists and designers additional tools to differentiate product offerings and strengthen brand identity through enhanced visual color effects. They offer outstanding performance and versatile application possibilities, as well as brilliant color saturation and a luminous, slightly sparkling finish. n

Acknowledgement:

The authors would like to thank Kirsten Fritsche for providing the durability testing data and reviewing of this article.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!