ISO-Free Urethane Technology Lengthens Pot Life, Shortens Cure Time

A urethane primer-surfacer formulated with PARALOID Edge technology is applied to a car fender at Dow’s coatings research lab in Midland, MI.

Industrial coatings that offer faster finishes are in demand as end users seek to improve productivity and/or accelerate return-to-service time. When formulating two-component (2K) polyurethanes, however, speed has been stymied by an ongoing trade-off between pot life and drying time. Slowing the reaction between the base resin (Part A) and the isocyanate crosslinker (Part B) provides a much-needed extension of pot life; it also results in longer drying times. PARALOID™ Edge ISO-free* technology (*manufactured without isocyanate) developed by Dow Coating Materials, a business unit of The Dow Chemical Company, utilizes an alternate urethane crosslinking system that decouples pot life from ambient cure time, allowing formulators to optimize both properties.

The Need for Speed

Speed is a competitive advantage across the industrial coatings space. Optimizing cycle time improves daily output, reduces labor cost and increases customer satisfaction. In automotive refinishing, the need for speed is magnified by a rebounding economy that has put more new cars on the road1 and industry consolidation that has left fewer body shops in operation.2 While many factors affect cycle time in automotive refinishing, a universal opportunity for improvement lies in accelerating the dry speed of polyurethane coatings.

Automotive refinishers use approximately 60 million pounds of polyurethanes per year.3 Most are applied as 2K coatings based on aliphatic diisocyanates and acrylic polyols.4 These materials offer excellent weather resistance, including resistance to UV degradation and yellowing; exceptional color and gloss retention, even after a very long exposure time; outstanding resistance to water, oil and chemicals; and excellent hardness and scratch resistance. In the absence of plural spray equipment or heat-assisted curing, however, these high-performance properties come at the cost of longer dry-to-sand time after primer application and longer dry-to-buff time after topcoat application. These drawbacks are in addition to limited pot life. Once 2K polyurethanes are mixed, spray time may be as short as a few hours.

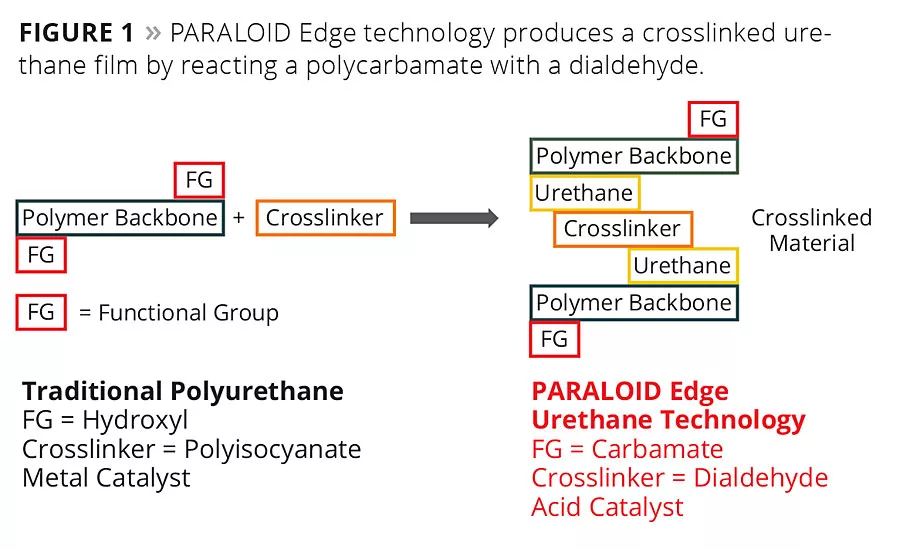

PARALOID Edge technology eliminates the cure speed/pot life trade-off that is standard practice when formulating with isocyanate-based crosslinkers for ambient-cure applications. As illustrated in Figure 1, this novel technology employs a carbamate-based functional group, a dialdehyde crosslinker and an acid catalyst. In addition to fast ambient dry speed and long pot life, this technology addresses formulator and applicator interest in isocyanate-free crosslinking systems to help improve the environmental, health and safety profile of the formulated coating.

Primer Benefits

The automotive refinishing process involves multiple coats of paint and multiple periods of waiting for each coat of paint to dry. After filling and sanding the area to be refinished, several coats of primer-surfacer are spray-applied. The primer is allowed to dry, then sanded and cleaned before the final painting process begins. Decreasing the dry time of the primer-surfacer would significantly improve the turnaround time for a refinish paint job and thereby increase a shop’s productivity.5 Table 1 provides a starting formulation for a 2K urethane automotive refinish primer-surfacer based on PARALOID Edge.

To demonstrate ambient cure speed, a primer-surfacer formulation was spray applied to cold rolled steel panels (sanded with 80-grit sandpaper) in two coats with a 10-min flash time after application. The coated panels were stored in a controlled temperature and humidity chamber during the drying process. Sandability was determined by the time required for the coating to be hand sanded with 320-grit sandpaper without caking the paper and any residual material on the paper was easily shaken or knocked off.

As demonstrated in Table 2, the primer-surfacer powered by the new technology had a short time to sand (40 min). By comparison, a commercial isocyanate-containing polyurethane primer-surfacer took more than four times longer – it required 180 min of dry time before sanding.

Made to Stick

Adhesion and solvent resistance are key performance properties required of primer-surfacers in automotive refinishing. Table 3 summarizes the solvent resistance and the crosshatch adhesion results for primer-surfacers based on PARALOID Edge technology. MEK double rubs exceeded 100 after 24 h and 200 after seven days. Crosshatch adhesion was measured via ASTM 3359 with a 3 mm blade for the primer-surfacer, as well as for the same primer-surfacer plus commercial black base and clear topcoat. After seven days, panels with the primer-surfacer and the primer-surfacer/color coat/clearcoat demonstrated and maintained good adhesion.

Overnight Pot Life

As noted, a key feature of PARALOID Edge technology is the ability to decouple pot life from cure speed and coating performance. To demonstrate this feature, a primer-surfacer formulation was prepared and sprayed within an hour and then again after standing at room temperature for 6, 16 and 24 h to determine the effect of pot life on cure speed and coating properties. In addition to sandability, solvent resistance was measured after the coating cured for one and seven days. All the coatings sanded well after 40 min of dry time, demonstrating that the fast sandability was not affected by aging the formulation for up to 24 h. MEK resistance after one day was slightly lower for the formulations that stood for 16 and 24 h; however, after seven days, the same solvent resistance was observed for all the primers sprayed at the various times. Similar adhesion to metal by crosshatch was observed for all of the primers, with a slight loss of adhesion after seven days.

Topcoat Options

While the majority of isocyanate-based polyurethanes in automotive refinishing employ an acrylic polyol resin, this new technology is notable for offering systems based on both alkyd and acrylic resins. This additional flexibility presents formulators with greater customization options when balancing formulation cost with the coating performance requirements of primers versus topcoats. In addition to commercializing an alkyd-based system for automotive refinish primer-sealers, Dow is developing acrylic-based systems for topcoats that offer excellent UV resistance in addition to cure speed and pot life advantages. Formulation details and coating properties based on initial testing are presented in Table 4.

Wait Not, Waste Not

Choosing between longer pot life and faster cure time is an ongoing challenge when formulating 2K polyurethanes for ambient-cure systems. In automotive refinishing, applicators must accept sub-optimal dry times in order to maintain workable levels of pot life. PARALOID Edge ISO-free urethane technology is an ambient curing, isocyanate-free coating technology that decouples pot life from cure speed. In automotive refinishing, this technology offers end users a drop-in solution that can accelerate cycle time, help improve profits and reduce material waste – all while providing an enhanced environmental, health and safety profile.

References

1 Jesse, S. Flat December Fails to Tarnish ‘Another Great Year for Auto Sales’, (www.autonews.com), January 3, 2014.

2 Automotive Aftermarket Industry Association, Digital 2013 Collision Repair Trends.

3 Center for the Polyurethanes Industry 2012 End-Use Market Survey.

4 Aliphatic Diisocyanates Explained, Fast Facts and Figures, American Chemistry Association.

5 Wall, C.A.; Richards, B.M.; Bradlee, C. The Ecological and Economic Benefits of UV-Curing Technology, RadTech Report, March/April 2004.

™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

For more information, visit www.dow.com/coatingmaterials.

By John Argyropoulos, Nahrain Kamber, Paul Popa and David Pierce, Dow Coating Materials, Collegeville, PA and Midland, MI

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!