Cobalt-Free Catalyst Gives New Life to the Alkyd Coatings Market

Recently, there has been renewed interest in alkyd technologies as environmental concerns have shifted and resin manufacturers strove to use bio-renewable resources. Alkyd resin manufacturers have found low-VOC options using higher solids resins (requiring less solvent) and water-based or water-reducible resins. One obstacle faced when using these new technologies was keeping the same drying characteristics of the conventional paint. Conventional solvent systems had excellent drying characteristics; with the new low-VOC options, typical paint driers based on metallic salts such as cobalt, zirconium and calcium did not provide the required cure. It was difficult for alkyds to compete against acrylic and latex options in the market.

This article highlights a new cobalt-free catalyst that helps to achieve the necessary cure time as well as improve properties associated with water-based, high solids alkyds and alkyd-modified resins. The catalyst provides the missing piece in new, low-VOC alkyd formulations, and kills two birds with one stone by curing the coating without the use of cobalt. Alkyd resins offer excellent performance in the decorative and light-end industrial paint markets, are cost effective and can be derived from renewable resources. With the introduction of this new catalyst, alkyd resins can now better meet the demands of today’s market.

Novel Catalyst

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc.

|

| Figure 1 Click to enlarge |

The mechanism of driers in the curing process has been thoroughly studied and is well understood. It involves radical processes to attain polymerization of the unsaturated resins present in paint/ink formulations via activation of alkyl hydroperoxides by the metallic salts/complexes.(1,2) Although it was initially created by the detergent industry as a tomato stain bleaching complex, the new catalyst has been found to activate the alkyd drying process in a similar fashion.

Previous work to meet the challenges of curing new alkyd resins was based on the modification of traditional metal carboxylates. The new product, however, is the result of a very different approach. Unilever had done extensive research on metal-based catalysts for stain bleaching in laundry products. Iron-based catalysts with pentadentate donor ligands were studied in detail (Figure 1). Research has shown that these iron-based catalysts activate hydroperoxides originating from the unsaturated food oils (such as olive or sunflower oil) typically present in tomato stains. Subsequently, radicals are formed that give rise to oxidation of other unsaturated oils, which then form other peroxides with dioxygen (Figure 2).(3)

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Figure 2 Click to enlarge |

These radical processes are similar to those described for the paint/ink-drying processes,(1,2) which led to the hypothesis that the catalysts studied for detergent stain bleaching might also be active for polymerization of unsaturated resins used in paints and inks. Preliminary studies using linseed oil supported this hypothesis and showed that catalysts based on ligands L1 and L2 (Figure 1) are much more active than conventional cobalt carboxylates for drying linseed oil.(4) On a molar basis, the activity of the catalysts was found to be 10-100 times more active than what had been observed for the cobalt carboxylate.(4) As the compound with ligand L1 is more synthetically viable, subsequent detailed studies were done on this compound.

Experiments and Results

Dry Time

Water-based Alkyds

The new catalyst from OMG, hereafter called Borchi® OXY - Coat (BOC), has now been tested in many alkyd resins including standard oil-based, high solids and water-based types. Surprisingly, water-based alkyds required the least amount of BOC for suitable dry times. Addition rates of 0.5-2.0% based on total solids were enough to cure most resin systems, and in most cases no additional secondary driers were needed. Gloss and hardness results are similar to those in traditional systems.

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Figure 3 Click to enlarge |

New resin development consists of a range of modified resins, including modified polyurethane dispersions. These resins are also oxidatively cured and require a curing agent. As shown in Figure 3, Borchi OXY - Coat is highly effective in these systems when compared to cobalt. In the formulation including BOC, dry time was reduced by over 50% initially, and shows a decrease in dry time after 2 months in storage.

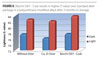

Other metals frequently used for curing modified waterborne alkyds are combinations of manganese (Mn) and zirconium (Zr). Figure 4 shows an improvement when using the Borchi OXY - Coat over the Mn, Zr combination in a modified polyurethane dispersion.

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Figure 4 Click to enlarge |

Another benefit seen with Borchi OXY - Coat in waterborne alkyds is excellent performance in adverse curing conditions. The performance of cobalt driers under conditions of low temperature and high humidity is often poor, with drying times being extended considerably (by 50% or more). Drying tests for several different resin systems under low-temperature and high-humidity conditions showed the performance of Borchi OXY - Coat is not as sensitive to such adverse conditions (Figure 6). In fact the BOC showed better dry times compared to the standard cobalt, zirconium and calcium drier package.

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Figure 5 Click to enlarge |

High Solids Alkyds

Unlike standard drier packages, the optimal addition level of Borchi OXY - Coat is resin dependent and requires testing with each resin type to determine proper levels. In many instances, BOC can act as a standalone compound, requiring no additional driers. In some cases, such as with high solids resins, the addition of a calcium, zirconium, or potassium drier can be used to obtain required hardness or enhance the through cure (Figure 7).

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Figure 6 Click to enlarge |

Improvement in Color

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Figure 7 Click to enlarge |

When discussing an iron catalyst, one question that comes to mind is, will there be a yellow tint in the final coating? Another surprise observed with BOC is that there is improved color as compared to standard drier packages (Table 1, Figure 8).

This can be explained by the composition of the molecule. Actual levels of iron in the supplied catalyst are parts per million. Due to the activity of the BOC, the material is supplied as a 1% solution in propylene glycol. The activity of the catalyst comes from the ligand structure; the iron level in the final coating is at trace levels and therefore does not contribute any color.

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Table 1 Click to enlarge |

Anti-Skinning Agents

Courtesy of OMG Americas, Inc. Courtesy of OMG Americas, Inc. |

| Figure 8 Click to enlarge |

The use of methyl ethyl ketoxime (MEKO) anti-skinning agents is necessary in typical solvent-based alkyds to increase open time and keep the surface from skinning in the can during storage. In cobalt-based systems the MEKO is able to work as an anti-oxidizing agent as well as complex with the cobalt to reduce its activity. MEKO cannot complex with the iron in the system, therefore, it is not as effective and more may be required. Alternative oxime- and phenol-free anti-oxidants are available, such as the Ascinin® Antiskin line from OMG, and work effectively with the catalyst in high solids systems. The use of anti-skinning agents in water-based alkyds is not usually necessary.

Conclusion

Lab tests demonstrate Borchi OXY - Coat can reduce dry times, prevent loss of dry, cure in adverse conditions, and improve color in waterborne alkyds and alkyd modified resins. In high solids resins the use of secondary driers may be necessary to obtain optimal dry time and hardness. Borchi OXY - Coat, along with new resins in the market, has given new life to the alkyd coatings market. It will enable resin suppliers to continue to develop low-VOC and waterborne alkyd resins, including those composed from renewable resources.

This article is based on a paper that was presented at the 2010 Coating Trends and Technologies Conference, sponsored by PCI Magazine and the Chicago Society for Coatings Technology.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!