Novel Rheology Modifiers

for Near-Zero-VOC Waterborne Coatings

Waterborne coatings, introduced in the 1960s, are complex, multiphase fluids. To control the target rheological properties during manufacture, storage and application, typically about 0.1-1.5 wt% of a rheological additive is added to the coating formulation. High-molecular-weight cellulosics, such as hydroxyethylcellulose (HEC), remain the workhorses for controlling the rheology of high-PVC (pigment volume concentration) (45-85%) waterborne coatings. However, to achieve the application properties and gloss of solventborne alkyds in low-PVC (20-40%) waterborne coatings, the use of cellulosics remains an elusive goal.1

To fill this need, during the 1980s a new class of water-soluble polymers was developed and commercialized. They are referred to as hydrophobically modified water-soluble polymers (HM-WSPs). Currently there are three classes of commercial HM-WSPs: (1) hydrophobically modified hydroxyethylcelluloses (HM-HECs); (2) hydrophobically modified nonionic synthetic polymers (HM-NSPs); and (3) hydrophobically modified alkali-soluble emulsions (HASEs).2 Chemically, HM-WSPs are water-soluble polymers that are grafted with a relatively small amount (<5%) of lipophilic groups. They are also called “associative thickeners” (ATs) as they non-covalently associate among themselves in an aqueous environment and/or associate with the dispersed particles (binders, pigment, etc.) through their hydrophobes to form a three-dimensional inter-chain network. The formation of this three-dimensional network provides enhanced viscosity, stabilization of the binder and modulation of the coating rheology under different shear rates.

Among the three classes of commercial HM-WSPs, HM-NSPs have gained commercial popularity in formulating low-PVC coatings using small particle binders because they provide good flow and leveling, spatter resistance, good film build, good gloss and film integrity. Chemically, they are fairly low-molecular-weight (6000-100,000 Daltons) linear polymers bearing alkyl or aryl/alkyl hydrophobes at chain ends. In addition, they can also bear relatively small-size internal hydrophobes as part of the polymer backbone. It has been found that the rheological properties of an HM-NSP are primarily dictated by (1) molecular weight, (2) the type of hydrophobe(s) grafted (internal and terminal) and (3) the amount of the hydrophobe grafted.

Since the inter-chain hydrophobic association and the adsorption behavior for HM-NSPs are non-specific, they are significantly affected in conjunction with surface-active agents and water-miscible VOCs. In fact, one of the major challenges in using HM-NSPs is to minimize or prevent viscosity loss upon tinting and provide balanced application properties, such as good hiding, optimal sag/leveling balance, good color acceptance and no color change on aging.

Due to increasing government and public concerns for environmental safety and human health, the use of VOCs in waterborne coatings is discouraged. In addition, stricter global regulations are being enforced to substantially minimize or even eliminate the use of VOCs in coatings. Unfortunately, curtailing or eliminating the use of VOCs adversely affects the application properties (open time, flow and leveling, prevention of foaming, etc.) and the final film properties (gloss, hardness, weather resistance) of the coatings.

Currently, to be compliant with VOC regulations, low- to zero-VOC waterborne coatings are manufactured using small-particle-size polymeric binders that have low minimum film forming temperatures. Since these binder particles are stabilized with novel stabilizer systems (surfactants and/or hydrophilic polymers), the interactions between the binder and the HM-NSP change, leading to de-stabilization of the formulated coating. This, in turn, affects the application and dried film properties.

The global coatings industry faces the challenge of designing products with low to zero VOCs, allowing them to remain compliant with regulations and public environmental concerns and still meet consumer quality expectations. This is made more difficult as the definition for “low VOC” and “zero VOC” has not been globally determined or accepted. This in turn puts more pressure on additive suppliers to design and deliver low- to virtually-zero-VOC3 products that meet the demanding performance of today’s coatings.

The objectives of the present work were two-fold: (1) develop novel rheology modifiers for formulating low- to zero-VOC waterborne coatings using very low- to virtually zero-VOC binders to deliver target rheological properties, and (2) understand the effect the molecular structure of the rheology modifiers has on rheological properties.

The performance features, including low- and high-shear viscosity, flow behavior and colorant response of these HM-NSPs, are discussed in this article.

Experimental

Materials and Formulas

Rheology Modifiers

The details of the HM-NSPs or rheology modifiers (RMs) used in the present study are shown in Table 1. They were synthesized by varying their 1) molecular weight, 2) hydrophobe type and 3) hydrophobe content. All the HM-NSPs are based on polyether backbones. They are near-zero-VOC and are free of alkylphenol ethoxylates (APEOs).

Binders

The details of the binders used to formulate the coatings are shown in Table 2.

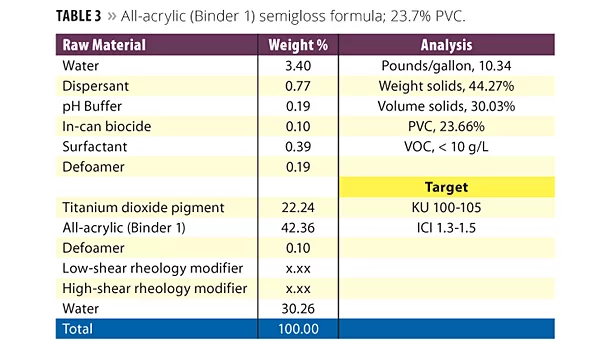

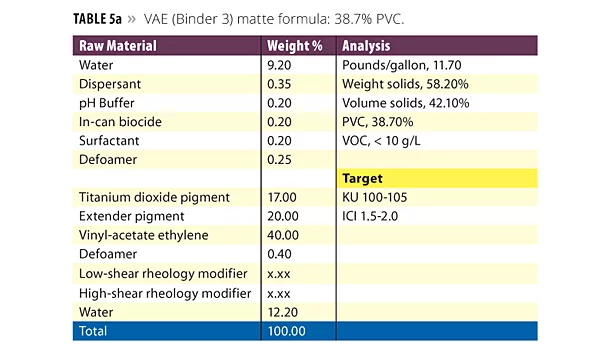

Coatings Formulas

The ingredients and amounts of raw materials used to prepare the coatings using various binders are shown in Tables 3-5.

Coatings Preparation

The following procedure was employed to achieve the targeted Stormer and ICI viscosities. Master batches of each coating formulation were made on a high-speed Dispermat mixer using a Cowles blade. The experimental HM-NSPs as well as a small percentage of water were withheld. Aliquot samples of the master batch were then thickened with Polymers A through I to a predetermined target Stormer viscosity (~100-105 KU). The high-shear viscosity (ICI, Poise) was also recorded for each coating. Thickening efficiency (TE) (shown below) is defined as the wt% of the “dry” HM-NSP needed to achieve a Stormer viscosity of 100 KU for the wet coatings.

TE = 100 x (Weight of the HM-NSP on a dry basis/ Total weight of the wet coatings)

The lower the TE numbers, the more efficient the HM-NSP in achieving the target Stormer viscosity. Experimental polymers that provided good TE but low ICI viscosity were appropriately combined with experimental polymers that provided good ICI viscosity to achieve a Stormer viscosity of ~ 100-105 KU.

After an overnight equilibration, the in-can and application properties were measured for the various coatings.

Rheological Measurements

The rheological properties of the coatings were measured using a TA Instruments ARG2 rheometer. Each sample was pre-sheared at a stress of 100 Pa for 10 sec. The sample was then allowed to recover with an oscillatory time sweep at 6.28 rad/sec for 60 min. Frequency sweeps were then performed on each sample from 0.6283-62.83 rad/sec. All samples were covered with a layer of oil to prevent evaporation and run at stresses in the linear viscoelastic region.

Test Methods

Test methods used to evaluate various coating properties are shown in Table 6.

Results and Discussion

Commercial waterborne architectural coatings are usually characterized by a low- and a high-shear viscosity. Low-shear viscosity (also known as Stormer viscosity, measured in Krebs Unit or KU), typifies the “in-can” or package viscosity and other low-shear processes, such as sag, leveling, pigment settling and syneresis. The high-shear viscosity (also known as ICI viscosity) is usually associated with the coatings application processes, such as brushing, rolling and spraying. HM-NSPs are commonly used to modify both the low- and the high-shear viscosity. In practice, a single HM-NSP rarely provides both the target low- and high-shear viscosity. Therefore, it is a common practice in the coatings industry to use a combination of two or more HM-NSPs to achieve the target rheology. Typically, an HM-NSP that efficiently builds low-shear viscosity and another HM-NSP that builds high-shear viscosity are used. Since the chemical compositions and structures of the low- and high-shear HM-NSP differ, their overall rheological response depends on the binder system and other formulating aids used. For designing commercial waterborne coatings using a given binder system, it is important to assess a priorithe rheological response of the individual HM-NSPs that are to be used to formulate the coatings. This knowledge helps coatings formulators make judicious choices of appropriate HM-NSPs to achieve the target low- and high-shear viscosity and other application properties.

All-Acrylic Binder (Binder 1)

Evaluation of Experimental HM-NSPs as Single Polymer

The experimental HM-NSPs (Polymers A-I) were evaluated in a low-VOC (VOC <10 g/L) semigloss (PVC = 23.7%) coatings formula containing the all-acrylic binder (Table 3). An appropriate amount of each of the HM-NSPs was added to the coatings formula to achieve a target Stormer viscosity of ~100-105 KU. The amount of the polymer needed to achieve the target Stormer viscosity is indicated on the bar for each polymer (Figure 1).

Polymers C and D belonged to the same chemical class and bore weakly associative alkyl groups. However, they significantly differed in their weight average molecular weight (Mw). Polymer C had a Mw twice that of Polymer D. Intriguingly, despite their significant difference in Mw, their TE was about the same (~1.65 wt%). The results suggest that for weakly associative polymers, Mw has very little impact on building low-shear viscosity. This could be due to weaker association between the polymer hydrophobes and Binder 1.

For other polymers, the TE primarily depended on their molecular weight and the type and amount of hydrophobe grafted at their chain termini.

It was found that the TE of Polymer B was lower than that of Polymer A. While both the polymers belonged to the same chemical class (end-capped with strongly associative hydrophobe groups), Polymer B differs from Polymer A in that the former has a Mw one half that of the latter. The enhanced TE of Polymer B is probably due its ability to associate strongly with the all-acrylic binder and form a strong network in the dispersed phase. We propose that, for the all-acrylic-based coatings, the Stormer viscosity (low-shear viscosity) is dominated by the dispersed phase viscosity arising from the association of the HM-NSP chain ends onto the binder surface. Work is underway to shed light onto this finding by measuring relative adsorption of Polymer A and B onto Binder 1.

Polymers F and G were end-capped with complex bunched hydrophobes. So far as the relative amount of hydrophobe grafted onto the polymer chain ends is concerned, Polymer F had about two times higher hydrophobe content than Polymer G. Also, Polymer F had significantly lower Mw (~42% lower) than Polymer G. As can be seen in Figure 1, Polymer F was about two times more efficient than Polymer G in achieving the same Stormer viscosity (Figure 1). The significantly enhanced thickening of Polymer F is attributable to its lower Mw and higher hydrophobe content per unit mass. It was found that Polymer B was more adsorptive than Polymer G onto the all-acrylic binder.

Polymer H, bearing a combination of rigid complex bunched hydrophobes and strongly associating hydrophobes, showed greater TE compared to Polymer I that was devoid of strongly associating hydrophobes.

Polymer K, a hydrophobically modified hydroxy-ethyl-cellulose (HM-HEC) was more efficient than its lower-molecular-weight counter-part, Polymer J.

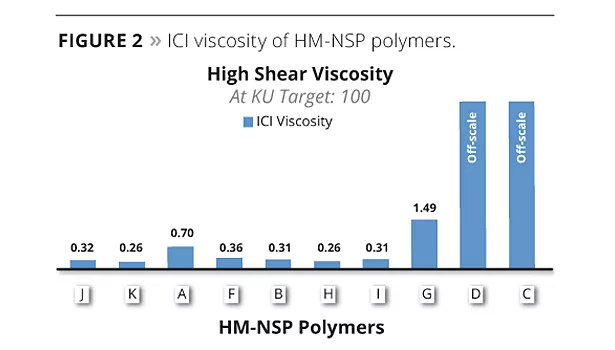

All the experimental HM-NSPs that had good TE (<0.6%) provided very little (0.3 poise) ICI viscosity. The weakly associative polymers, Polymer C and D, gave good ICI viscosity (1.6-1.7 poise) but at the expense of high loading (TE = 1.6-1.7 wt %). Polymer G, whose chain ends were capped with complex polyhdrophobes, also afforded a moderate ICI viscosity (1.45 poise), but again at a high loading (TE = 1.13 wt %). Based on the TE and the ICI viscosity of the experimental HM-NSPs, one can say that the more efficient the polymer in building the target Stormer viscosity the lower the ICI viscosity (Figure 2).

None of the polymers by themselves were able to deliver a combination of the target Stormer viscosity (~100-105 KU) and the ICI viscosity (>1.5-2.0 poise) in this formula.

For further discussion hereafter, we describe Polymers C and D as weakly associative polymers and Polymers A, B and F-K as strongly associative polymers.

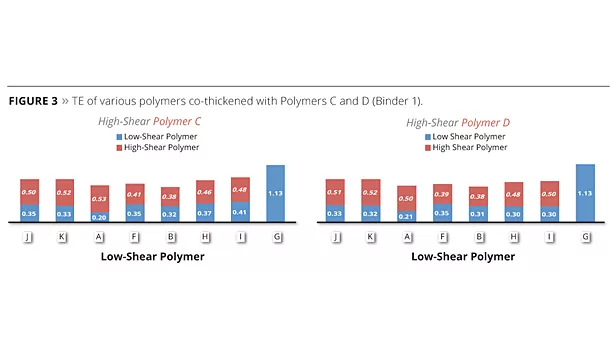

Evaluation of Polymers in Combinations

A second set of coatings was formulated using a combination of strongly associative polymers (Polymers A, B and F-K) and weakly associative polymers (Polymers C and D) to achieve a target Stormer viscosity of 100-105 KU. The use level of Polymers C and D (shown in red bars in Figure 3) ranged from ~0.4-0.5 wt%. For strongly associative polymers (Polymers A, B and F-K) (shown in blue bar), the use level ranged from 0.2-0.4 wt%.

Composite flow curves were generated by plotting Brookfield, Stormer, and ICI coating viscosities onto one graph (Figure 4). Since all coatings were formulated to have the same Stormer and ICI viscosity, one would expect that the curves would intersect at these two “single point” viscosity measurements. The low-shear rate (0.10- 10.0 sec-1) regime viscosity measured by the Brookfield viscometer at various shear rates was not held constant, and as such, significant differences can be seen with respect to viscosity. These observed differences were considered extremely significant as these low-shear rate regime viscosities would define the balance of sag resistance and flow and leveling of waterborne coatings.

HM-NSPs play a major role in controlling coating viscosity in this shear regime and the ultimate post-application properties. Figure 4 displays the differences in low-shear Brookfield viscosities of the HM-NSPs co-thickened with Polymers C and D. Polymer combinations A and C, B and C and G, each exhibit a more Newtonian flow and lower viscosity compared with the shear-thinning, higher viscosities of the other HM-NSP combinations. The same rheological trends were observed for all the HM-NSPs when high-shear Polymer C was replaced with high-shear Polymer D (Figure 4).

Sag and Leveling of All-Acrylic -Based Coatings

Sag resistance and leveling were measured using ASTM methods as previously listed (notched bar and grooved rod). Figure 5 shows the plot of sag resistance, measured in mils, and leveling. The leveling scale is based on a numerical scale from 1-10, with 10 being excellent and 1 being poor (no leveling). Typically, a higher sag value translates to poorer flow and leveling as these are two antagonistic properties. Note that the rating values differ depending upon application and performance requirements. For commercial coatings, a sag rating of 12 plus mils is typically required with a leveling rating of at least 7 or higher.

The sag resistance for both Polymers J and K is over 24 mils, with a leveling rating of 2-3. These polymers are high-molecular-weight HM-HECs that were developed for generating a strong shear-thinning flow curve with excellent sagging and suspension properties. Unfortunately, the leveling is negatively impacted and, as such, this class of polymers is not appropriate for use in semigloss to high-gloss low-PVC acrylic coatings that demand a much tighter balance of flow and leveling. Polymer combination A and C and B and C had relatively low sag resistance ratings. These polymers belonged to the same chemical class (A and B having strongly associative hydrophobes, and Polymers C and D having weakly associative hydrophobes) but differing in Mw. Polymer G (alone) with complex bunched hydrophobes had poor TE and poor sag resistance. The complex bunched hydrophobes bearing polymers (Polymer F, H and I) in combination with Polymer C provided drip-free sag resistance at over 12 plus mils. Leveling was excellent for these combinations with the exception of Polymer I (in combination with Polymer C or D).

By comparing the sag resistance and leveling data shown in Figure 5 to the composite flow curves shown in Figure 4, it is clear that low-shear viscosity, measured using a Brookfield viscometer, is an important rheological parameter to correlate with Stormer and ICI viscosities. This parameter could also be used to judge the overall in-can appearance, rheology during application and post application properties of coatings.

Brush-Applied Leveling

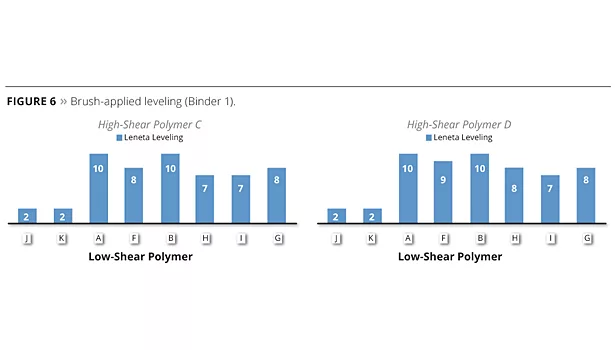

Generally, for pre-screening and rating the sag resistance and leveling of waterborne coatings, test methods from ASTM, such as Leneta, are useful. However, they do not always simulate the same shear rate conditions (shear rate >10,000 sec-1) one might find in real life roller and brush application. Therefore, for developing commercial coatings, it is a good practice to apply coatings using both roller and brush, and evaluate the end-use application properties.

Figure 6 shows the brush application results for the coatings applied at an equal spread rate of 250 ft2 per gallon. These brush-outs were visually measured against a standard set of ASTM brush-outs using the same rating system previously described for Leneta application. Clearly, the high-Mw hydrophobically modified HECs exhibited extremely poor flow. Due to structural variation of the polymers (A-I), the brush-out leveling for different polymers was different. Nonetheless, all the polymers provided decent ratings. The results suggest that the sag resistance and leveling are inter-related and they depend on the HM-NSP structure.

Rheological Measurements for All-Acrylic (Binder 1)-Based Coatings

To shed light on the correlation between sag and leveling of the all-acrylic-based coatings, we studied their rheological characteristics. The results are discussed below.

When considering the balance between sag and leveling in coatings, each of the individual components can be considered. Coatings that have very good sag resistance have very high elastic modulus. By contrast, coatings with good leveling performance have lower elastic modulus and more dominant viscous modulus. It makes sense then to consider that contributions to good sag are elastic (modulus) in nature and contributions to good leveling are more viscous (modulus) in nature. The balance between sag and leveling can also be seen as a balance between the elastic and the viscous modulus (G’, G”) or tanδvalues (G”/G’) that are close to 1 (Figure 7). Coatings that have too high of an elastic modulus will have good sag resistance but poor leveling. On the other hand, coatings with very high viscous modulus will have good leveling but poor sag resistance. After pre-shearing a sample and then performing a recovery time sweep followed by a frequency sweep, correlations can be seen between coatings that have good balance of sag and leveling (10/10) and tanδvalues (~1). Good correlation also exists between sag values and G’ values at 1 rad/sec as well as between leveling values and G” values at 1 rad/sec.

As can be seen in Figure 8, coatings formulated with Polymers F, H and I in combination with Polymer C had a tanδvalue approaching unity. By contrast, coatings formulated with Polymers K and J had tanδvalues <1 and Polymers A and B had tanδ>1. These rheological data are consistent with the sag and leveling measured for these coatings by ASTM test method.

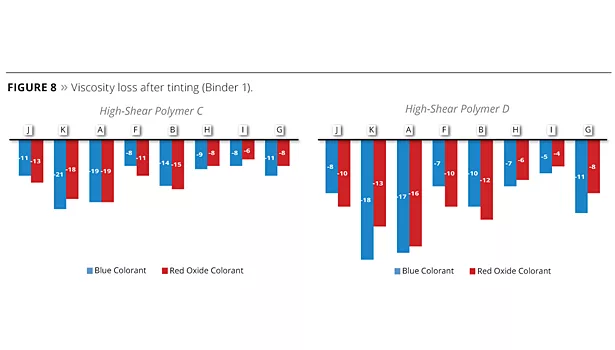

Viscosity Loss Upon Tinting

Each of the coatings was tinted with a universal colorant at a 3 percent by total weight loading. A phthalo blue and red iron oxide colorant was tested. After adding the colorant, Stormer viscosity was measured. Typically, in the coatings industry, a loss of <10 KU is considered acceptable. Additional drop in KU (>10) can negatively impact the application and performance properties of the coating. The viscosity loss encountered by each polymer is shown in Figure 7. As can be seen, all the polymers occasioned a viscosity loss upon tinting. However, Polymers H and I had the lowest viscosity loss (<10 KU) (Figure 8).

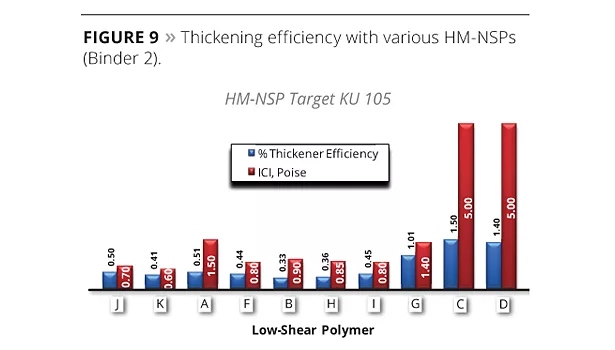

Styrene-Acrylic Binder (Binder 2)

A styrene-acrylic binder was evaluated in a 38% PVC semigloss coating (Table 4). Each of the experimental HM-NSPs was tested at a target Stormer viscosity of 100 KU. The %TE for the experimental polymers was determined (Figure 9). The %TE and ICI viscosity response for the polymers were very similar to their responses with the all-acrylic binder.

A second set of paints was made using a combination of the strongly associative polymer and the weakly associative polymers (Polymers C and D) to achieve a Stormer viscosity of ~100-105 KU. The results are shown in Figure 10.

Similar to the study carried out using the all-acrylic binder, composite flow curves were generated by plotting the low-shear Brookfield, Stormer and ICI coatings viscosities (Figure 11). The composite viscosity profiles of the styrene-acrylic binder-based coatings were more shear-thinning than the ones based on the all-acrylic binder. However, for the styrene-acrylic binder, the rheological trend was very similar to that observed for the all-acrylic binder. As can be seen, Polymers A, B and G were the most Newtonian in the low-shear rate regime (Figure 11).

Sag Resistance and Leveling

The sag and leveling trends of styrene-acrylic-based coatings were the same as those of all-acrylic-based coatings (Figure 12).

Vinyl-Acetate-Ethylene (VAE) Binders (Binder 3 and 4)

Due to their very low coalescing solvent demand, VAE binders have become binders of choice to formulate very low- and zero-VOC coatings. However, achieving optimal rheological performance and application properties are challenging with VAE binders compared to acrylic binders. The main reasons for this are described below.

VAE polymers are more hydrophilic as they are stabilized with adsorbed and/or grafted hydrophilic polymer chains (hydroxyethylcellulose, polyvinyl alcohol, etc.) onto their surface. Being hydrophilic, they tend not to associate/interact with the terminal hydrophobes of HM-NSPs. Consequently, network buildup in the dispersed phase is prevented or minimized.

VAE polymers have typically larger particle size (0.3-0.4 µm) binders than most acrylics, and, thus, there is less surface area with which HM-NSPs can interact.

To investigate the feasibility of using VAE binders in very low- to zero-VOC coatings, several experimental HM-NSPs were evaluated in two different VAE binders (Binder 3 and 4). In regard to particle size, Binder 3 has a larger particle size (0.35 µm) compared to Binder 4 (particle size = 0.30 µm). The details of these two VAE binders are shown in Table 2.

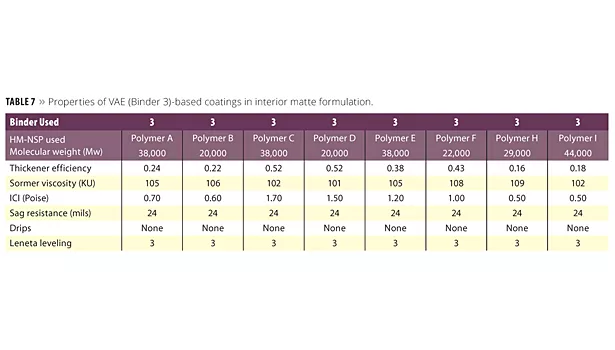

The performance properties of the various polymers (Polymers A-F and H-I) based on an interior matte formulation (Table 5a) based on VAE Binder 3 are shown in Table 7. As can be seen from the data, all the polymers provided poor leveling (rating of 3) with this particular binder.

To further investigate the effectiveness differences of the experimental HM-NSPs, a combination of an experimental HM-NSP and hydrophobically modified HEC (HM-HEC) (Polymer J) was investigated with Binder 3. Once again, regardless of the thickener package used, the leveling of all the coatings was the same (rating of 3). It appears that the hydrophilic polymer(s) present on the surface of this binder preclude the association of the HM-NSP hydrophobes, and consequently no dispersed phase network is formed.

Interestingly, using the alternative VAE Binder 4 in place of VAE Binder 3, optimal balance of sag and leveling was obtained with several of the strongly associative HM-NSPs, namely Polymers A, B, H and I. (Table 8). Polymer B provided the best overall balance of low TE, ICI viscosity, sag and leveling. Another interesting set of results was the high ICI viscosity obtained with the two weakly associative polymers (Polymers C and D). Notably, at the same TE, Polymer D gave significantly higher ICI viscosity than Polymer C, even though the use levels for both polymers were about the same. Based on the rheological data of the individual HM-NSP, it is proposed that excellent balance of properties could be obtained by using a thickener package of Polymer B and Polymer D, and adjusting the relative amounts of each.

Using a different formulation based on Binder 4 (Table 5b), thickener packages were evaluated to obtain optimal balance of sag and leveling. In this formulation, the use of HM-HEC (Polymer J) in conjunction with the experimental HM-NSPs was found to be more effective than various combinations of HM-NSPs for achieving optimal balance of sag and leveling, and optimal roller application properties (Table 9).

Conclusions

In the present study, a series of HM-NSPs were made by varying molecular weight, hydrophobe type and hydrophobe loading. These HM-NSPs were incorporated individually as well as in combination with other HM-NSPs (weakly associative ones) and HM-HECs into low- to zero-VOC coatings containing all-acrylic, styrene acrylic and two VAE binders. It was found that the low- and high-shear rheology of the formulated coatings depended on the molecular weight, hydrophobe type and hydrophobe loading. HM-NSPs with weakly associative hydrophobes were not efficient in building low-shear viscosity. HM-NSPs with strongly associative hydrophobes were efficient low-shear viscosity builders, but were poor ICI viscosity builders. It has been demonstrated that a judicious choice of two HM-NSPs – one being weakly associative and the other being strongly associative – can provide the target rheology for all-acrylic and styrene-acrylic-based waterborne coatings. The relative amount of the two HM-NSPs in the formulation can be adjusted based on the target rheology, binder type and the PVC of coatings.

Strongly associative HM-NSPs (Polymers H and I) in combination with weakly associative HM-NSPs (Polymers C and D) provided the desired rheology (Stormer viscosity, ICI viscosity and good balance of sag and leveling). These polymer combinations also retained good viscosity upon tinting (Stormer viscosity loss was <10 KU).

The rheological performance of these HM-NSPs in styrene-acrylic-based low- to zero-VOC coatings was similar to those for all-acrylic based coatings.

In the VAE-based coatings, several of the strongly associative HM-NSPs were very efficient Stormer viscosity builders. However, the degree to which the strongly associative HM-NSPs affected sag and leveling balance was largely due to the specific VAE binder used in the formulation. Based on the interior matte formulation (Table 5a) and using VAE Binder 3, it was not possible to obtain good flow and leveling. With this same formulation, using VAE Binder 4 in place of VAE Binder 3, several of the strongly associative HM-NSPs provided excellent balance of sag and leveling. It is believed that the difference in stabilization packages between these two VAE binders is the reason for the difference in rheology properties obtained in this formulation.

Using a different formulation based on Binder 4 (Table 5b), thickener packages were evaluated to obtain optimal sag and leveling balance. In this formulation, the use of HM-HEC (Polymer J) in conjunction with the experimental HM-NSPs was more effective than various combinations of HM-NSPs for achieving optimal balance of sag and leveling, and optimal roller application properties.

References

- K. Alahapperuma, K.; Glass, J.E. Progress in Organic Coatings 1992, 21, 53, and the references cited therein.

- Schaller, E.J.; Sperry, P.R. Handbook of Coatings Additives, Vol. 2, L. J. Calbo (ed.), Marcel Decker, N.Y., p. 105, 1992.

- Virtually zero-VOC for purposes of this paper is considered to be <0.1% based on Enhanced ASTM D-6886 test method.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!