Does Yellow Beat White?

Formulating a high-performance coating system has become an everyday challenge. Not only do the technical requirements need to be met, but more and more, economic aspects need to be considered as well. To meet these challenges, innovative new ideas and concepts in formulating high-performance coatings are required.

By optimizing the well-known chrome and nickel titanium yellow chemistries, which exhibit outstanding fastness and durability, a new class of pigments has been obtained offering a versatile tool for formulating economic and innovative coatings.

Customers who use these new formulations are achieving a 25-30% savings and at the same time receiving improved performance!

The improvement is accomplished by an innovative and proprietary technology to micronize the pigments while keeping their excellent weather and light-fastness as well as their exceptional temperature resistance.

The Pigments

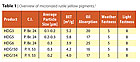

Typically, chrome and nickel titanium yellows show an average particle size of >1µm. After micronizing, a smooth and controlled downsizing of pigment particles the average particle size is about 0.3 µm (Figure 1).This micronization technique produces a narrow particle size distribution of spherical-shaped pigment particles (Figure 2), which enhances hiding power and opacity as well as significantly reduces abrasiveness.

A

detailed overview on several pigments optimized by this new micronization

technique and some of their properties is given in Table 1.

Performance

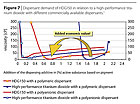

In modern coatings systems, the high performance of these types of inorganic pigments is a key asset. This is especially seen when they are used in combination with organic pigments where the hiding power and opacity of the inorganic pigments are crucial. In this case, the micronized grades with their unique hiding power will outperform a high-performance titanium dioxide grade (Figure 3).

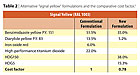

This exclusive property of the rutile yellow pigments allows substituting

titanium dioxide in formulations by achieving higher cost efficiency. Tables 2

and 3 show two examples of customary industrial coatings color shades.

The controlled and optimized particle size

distribution of the micronized rutile yellow pigments in combination with their

spherical shape allows higher gloss values for brilliant and glossy coatings

(Figure 5).

In the segment of high-value industrial coatings, the formulators’ focus is not

only on the coloristic properties of pigments or their light- and

weather-fastness, but also on their ease of stabilization in the coatings

system. The challenge is to control the economic efficiency positively while

maintaining a maximum of application-oriented flexibility and compatibility of

the formulation.

New Options - New Chances

These novel, micronized, rutile yellow pigments are proving to be true high performers in modern coating formulations. Besides their well-known exceptional properties like weather- and light-fastness or temperature resistance, they offer the formulator integral features that are most essential in formulating high-performing, cost-conscious coatings.The features include outstanding hiding power and opacity, reduced abrasiveness and the significantly beneficial dispersant demand compared to other pigments like titanium dioxide. This allows for a higher degree of flexibility and a higher technological compatibility. Therefore, these new pigments are an excellent alternative to the widely used titanium dioxide pigments.

Modern rutile yellow pigments combine synergistic as well as economic advantages to give the formulator the tool they need to develop high-performance, economically feasible formulations.

This article was also published in Farbe & Lack, May 2007.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!