Antimicrobial Coatings

This article explains various ways an antimicrobial is referred, used, evaluated and/or promoted in several markets, particularly focusing on coatings and building products applications.

The term ‘antimicrobials’ is generally defined as substances – or mixtures of substances – used to destroy or suppress the growth of harmful microorganisms whether they be bacteria, fungi, or virus, in or on a substrate or article where it is not desired. This article makes an attempt to simplify antimicrobials for readers in the industry and explain various ways an antimicrobial is referred, used, evaluated and/or promoted in several markets, particularly focusing on coatings and building products applications. Some of the government regulations on the claims and uses of antimicrobials in products are briefly reviewed, taking excerpts from published articles and cited websites.

Besides these various terms for anti-microbial concepts, in many industries terms like bactericides, fungicides, algaecides, virucides, preservatives and biocides are commonly used. For example, in the coatings industry, the term ‘biocide’ is historically employed to indicate preserving a wet formulation from microbial spoilage which, in most other industries like personal care or household markets, would be defined as a ‘preservative’.

In addition to these various terms to indicate chemicals that inhibit or destroy microorganisms, we are also exposed to layman’s terminology of ‘mildewcide’ or ‘moldicide’ to refer to chemicals controlling unsightly biological defacement on surfaces that are ‘black’. Even though it is implied primarily for fungal growth, it can also be caused by a consortium of other microorganisms including lower forms of algae, moss, amoeba, protozoa, etc. For non-microbiologists, these terms may be confusing with each term meaning different things depending on the implied uses and claims by different suppliers. Simply put, can all of these chemicals be referred to as antimicrobials irrespective of their applications, target organisms and mode of activity? The answer is yes, all of them are antimicrobials against one or another class of microorganisms under a given condition.

Government regulations on treated articles, including coatings with antimicrobials, and guidelines on claims come under the Federal Insecticide Fungicide and Rodenticide Act (FIFRA), EPA and FDA. Under FIFRA, an antimicrobial product that claims to control microorganisms such as bacteria and fungi requires registration. According to the EPA, an article or a substance that is treated with, or containing, a registered pesticide is defined as a treated article and is limited to protecting the article itself from microbial spoilage or contamination (for example paints supplemented with fungicides or bactericides to protect the paint in storage or after application, or preservative treatments used in wood to protect wood against insects or fungal infestation). The sole purpose of the treatment is to protect the articles themselves.(1)

Concerned with the increasing claims of treated products in the market having implied or explicit public health claims from many manufacturers beyond the intended and permitted purpose of protecting the article itself, thus giving a false sense of security to the public against disease-causing harmful bacteria, the EPA in 2000 issued a Pesticide Regulation Notice 2000-1 to clarify the Agency’s policy with respect to the scope of the treated article exemption. It is a guidance document that focuses on the various types of antimicrobial claims that the EPA considers acceptable or unacceptable. It simply classifies antimicrobial-treated products into two categories,

1.) Public health claim products are intended to control microorganisms infectious to humans in any inanimate environment. The most commonly used public health antimicrobial products include the following: sterilizers (sporicides), disinfectants, sanitizers, antiseptics and germicides.

2.) Non-public health claim products are used to control growth of odor-causing bacteria, algae, mildew, bacteria that cause spoilage, deterioration or fouling of materials and microorganisms infectious only to animals. This general category includes products used in cooling towers, jet fuels, paints, treatments for textiles and paper products. The EPA considers terms such as “antimicrobial,” “fungistatic,” “mildew-resistant” and “preservative” as being acceptable for exempted treated articles or substances, provided that they are properly, and very clearly, qualified as to their intended non-public health use. They also restrict use of these terms in product names or elsewhere in the labeling in bolder text than accompanying information. The EPA also considers trademarked product names of treated articles or substances (or reference to trademarked names of registered pesticides) as a potential public health claim and makes it ineligible to qualify under the “treated article exemption”.(2)

ASTM D 5589: Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Algal Defacement. This test method is for antimicrobial testing of dry coating films with respect to algae including cyano bacteria/blue green algae and green algae.(3)

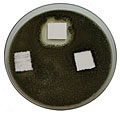

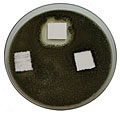

ASTM D 5590: Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Fungal Attack. This is an agar-based method evaluating coated surfaces for their resistance to commonly occurring indoor and exterior fungi such as Aspergillus niger, Penicillium sp. and Aureobasidium pullulans.(4)

ASTM D 3273: Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber. An accelerated antimicrobial test for determining the resistance of interior coatings to mold growth; useful in estimating the performance of coatings designed for use in interior environments that promote mold growth.(5)

ASTM D 2574: Standard Test Method for Resistance of Emulsion Paints in the Container to Attack by Microorganisms. An antimicrobial test method to demonstrate resistance of the wet products to bacterial contamination (spoilage) during long term storage prior to application. Typically, select environmental microorganisms are grown and challenged (introduced or inoculated) weekly into the product which is then tested for their total elimination or absence of their growth in 24, 72 and 96 hours.(6)

The Japanese Industrial Standard JIS Z 2801-2000: Antimicrobial Products – Test for Antimicrobial Activity and Efficacy. This method was originally developed to test the antibacterial activity of silver ions impregnated in rigid hydrophobic polymers. This method was developed by a consortium of workers comprised of manufacturers of silver-based antimicrobial agents, government-based research organizations and universities, and under organizations such as the Society of Industrial Technology for Antimicrobial Articles (SIAA).(7)

This method is a quantitative measurement method that tests survival of low-dose bacterial inoculum deposited between the tested antimicrobial surface and a thin plastic film that keeps the inocula wet and nourished in a nutrient-rich environment throughout the 24 h incubation at 35 ºC. This differs from other traditional methods of testing antimicrobial resistance in coatings surfaces where the surface is not kept deliberately wet or moist with a nutrient medium. Inoculum survival and growth in the other methods depends only on the moisture from either media or humidity created in the incubated unit, so only microorganisms that can survive some level of desiccation on the surfaces in 24 h can be recovered and can be compared to the non-treated surface. In this respect, the JIS Z 2801 method is so severe it is not necessarily a realistic surface contamination model for dry walls and other coated vertical surfaces.

In spite of this limitation, JIS Z 2801 has emerged as one of the industry standards for perhaps the ‘worst case scenario’ of a surface that retains wetness and permits microbial survival. Following the method as written for hydrophobic coatings surfaces, yields results that may provide useful information, but for hydrophilic and porous substrates and surfaces, a deviation in the inoculum delivery and validation for each different substrate would be required to get useful data. There is no one universal test protocol or one pesticide product that can demonstrate all the antimicrobial properties on all surfaces.

For more information contact Siva Microbiological Solutions LLC at www.sivams.com; or 215-499-1983; or info@sivams.com.

The term ‘antimicrobials’ is generally defined as substances – or mixtures of substances – used to destroy or suppress the growth of harmful microorganisms whether they be bacteria, fungi, or virus, in or on a substrate or article where it is not desired. This article makes an attempt to simplify antimicrobials for readers in the industry and explain various ways an antimicrobial is referred, used, evaluated and/or promoted in several markets, particularly focusing on coatings and building products applications. Some of the government regulations on the claims and uses of antimicrobials in products are briefly reviewed, taking excerpts from published articles and cited websites.

Terminology

Historically, the term ‘antibiotics’ is used in reference to controlling bacterial infections, specifically in humans. For substances that control or inhibit yeast and fungi, the term used is ‘anti-fungal’ whether on animate or inanimate substrates. Similarly, for inhibiting viruses, we refer to anti-viral substances.Besides these various terms for anti-microbial concepts, in many industries terms like bactericides, fungicides, algaecides, virucides, preservatives and biocides are commonly used. For example, in the coatings industry, the term ‘biocide’ is historically employed to indicate preserving a wet formulation from microbial spoilage which, in most other industries like personal care or household markets, would be defined as a ‘preservative’.

In addition to these various terms to indicate chemicals that inhibit or destroy microorganisms, we are also exposed to layman’s terminology of ‘mildewcide’ or ‘moldicide’ to refer to chemicals controlling unsightly biological defacement on surfaces that are ‘black’. Even though it is implied primarily for fungal growth, it can also be caused by a consortium of other microorganisms including lower forms of algae, moss, amoeba, protozoa, etc. For non-microbiologists, these terms may be confusing with each term meaning different things depending on the implied uses and claims by different suppliers. Simply put, can all of these chemicals be referred to as antimicrobials irrespective of their applications, target organisms and mode of activity? The answer is yes, all of them are antimicrobials against one or another class of microorganisms under a given condition.

Regulatory Aspects

With the defacement of buildings and paints following hurricane Katrina, there has been increased interest in either using or promoting products that are termed ‘antimicrobial’, particularly in the U.S. surface treatment coatings industry. In doing so, by extrapolating the functions, some public health claims are being attributed to products.Government regulations on treated articles, including coatings with antimicrobials, and guidelines on claims come under the Federal Insecticide Fungicide and Rodenticide Act (FIFRA), EPA and FDA. Under FIFRA, an antimicrobial product that claims to control microorganisms such as bacteria and fungi requires registration. According to the EPA, an article or a substance that is treated with, or containing, a registered pesticide is defined as a treated article and is limited to protecting the article itself from microbial spoilage or contamination (for example paints supplemented with fungicides or bactericides to protect the paint in storage or after application, or preservative treatments used in wood to protect wood against insects or fungal infestation). The sole purpose of the treatment is to protect the articles themselves.(1)

Concerned with the increasing claims of treated products in the market having implied or explicit public health claims from many manufacturers beyond the intended and permitted purpose of protecting the article itself, thus giving a false sense of security to the public against disease-causing harmful bacteria, the EPA in 2000 issued a Pesticide Regulation Notice 2000-1 to clarify the Agency’s policy with respect to the scope of the treated article exemption. It is a guidance document that focuses on the various types of antimicrobial claims that the EPA considers acceptable or unacceptable. It simply classifies antimicrobial-treated products into two categories,

1.) Public health claim products are intended to control microorganisms infectious to humans in any inanimate environment. The most commonly used public health antimicrobial products include the following: sterilizers (sporicides), disinfectants, sanitizers, antiseptics and germicides.

2.) Non-public health claim products are used to control growth of odor-causing bacteria, algae, mildew, bacteria that cause spoilage, deterioration or fouling of materials and microorganisms infectious only to animals. This general category includes products used in cooling towers, jet fuels, paints, treatments for textiles and paper products. The EPA considers terms such as “antimicrobial,” “fungistatic,” “mildew-resistant” and “preservative” as being acceptable for exempted treated articles or substances, provided that they are properly, and very clearly, qualified as to their intended non-public health use. They also restrict use of these terms in product names or elsewhere in the labeling in bolder text than accompanying information. The EPA also considers trademarked product names of treated articles or substances (or reference to trademarked names of registered pesticides) as a potential public health claim and makes it ineligible to qualify under the “treated article exemption”.(2)

Testing for Antimicrobial Products

Antimicrobials used in public or non-public health claim products have to go through a battery of testing using acceptable microbiological methods to show efficacy in the product in use. There are many test methods in microbiology described to demonstrate the antimicrobial nature of a substance and when it is incorporated in an article. There are various screening stages adopted that may include primary, secondary and in-use final testing. A typical primary-screening protocol involves testing for the minimum inhibitory concentration (MIC) of the chemical to be incorporated in an article. Normally the MIC is determined in an in-vitro system like growth media against a set of bacteria, fungi, virus and/or algae depending on the target microorganism. After getting selected in the primary screen, the substance enters the secondary screening process in an in-vivo system, meaning the application matrix in which it is expected to be incorporated. Because not all selected antimicrobial substances are expected to be universally acceptable in varied systems, they next go through the rigor of compatibility, stability and efficacy testing evaluations. Some examples of this rigor in coatings applications include the chemical stability in the formulation, pH compatibility, heat stability, color acceptance, shelf storage longevity, exterior weather sustainability, etc., in addition to testing for its bio-availability to function as an antimicrobial throughout the process.Methods for Antimicrobial Testing in Coatings

With so many scenarios for defining an antimicrobial, the challenge becomes how to test and what test methods to use for demonstrating and claiming broadly the ‘antimicrobial’ property of a treated article such as a coating.ASTM D 5589: Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Algal Defacement. This test method is for antimicrobial testing of dry coating films with respect to algae including cyano bacteria/blue green algae and green algae.(3)

ASTM D 5590: Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Fungal Attack. This is an agar-based method evaluating coated surfaces for their resistance to commonly occurring indoor and exterior fungi such as Aspergillus niger, Penicillium sp. and Aureobasidium pullulans.(4)

ASTM D 3273: Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber. An accelerated antimicrobial test for determining the resistance of interior coatings to mold growth; useful in estimating the performance of coatings designed for use in interior environments that promote mold growth.(5)

ASTM D 2574: Standard Test Method for Resistance of Emulsion Paints in the Container to Attack by Microorganisms. An antimicrobial test method to demonstrate resistance of the wet products to bacterial contamination (spoilage) during long term storage prior to application. Typically, select environmental microorganisms are grown and challenged (introduced or inoculated) weekly into the product which is then tested for their total elimination or absence of their growth in 24, 72 and 96 hours.(6)

The Japanese Industrial Standard JIS Z 2801-2000: Antimicrobial Products – Test for Antimicrobial Activity and Efficacy. This method was originally developed to test the antibacterial activity of silver ions impregnated in rigid hydrophobic polymers. This method was developed by a consortium of workers comprised of manufacturers of silver-based antimicrobial agents, government-based research organizations and universities, and under organizations such as the Society of Industrial Technology for Antimicrobial Articles (SIAA).(7)

This method is a quantitative measurement method that tests survival of low-dose bacterial inoculum deposited between the tested antimicrobial surface and a thin plastic film that keeps the inocula wet and nourished in a nutrient-rich environment throughout the 24 h incubation at 35 ºC. This differs from other traditional methods of testing antimicrobial resistance in coatings surfaces where the surface is not kept deliberately wet or moist with a nutrient medium. Inoculum survival and growth in the other methods depends only on the moisture from either media or humidity created in the incubated unit, so only microorganisms that can survive some level of desiccation on the surfaces in 24 h can be recovered and can be compared to the non-treated surface. In this respect, the JIS Z 2801 method is so severe it is not necessarily a realistic surface contamination model for dry walls and other coated vertical surfaces.

In spite of this limitation, JIS Z 2801 has emerged as one of the industry standards for perhaps the ‘worst case scenario’ of a surface that retains wetness and permits microbial survival. Following the method as written for hydrophobic coatings surfaces, yields results that may provide useful information, but for hydrophilic and porous substrates and surfaces, a deviation in the inoculum delivery and validation for each different substrate would be required to get useful data. There is no one universal test protocol or one pesticide product that can demonstrate all the antimicrobial properties on all surfaces.

EPA, OPP and OECD Antimicrobial Testing Programs

The EPA has focused its efforts on evaluating registered products that are most crucial to infection control such as sterilants, tuberculocides and hospital-level disinfectants. The manufacturer of any product bearing a public health claim is required to submit efficacy data to the Antimicrobials Division of the Office of Pesticide Programs (OPP) to substantiate the product’s effectiveness. The focus of the OPP Microbiology Laboratory is centered on the efficacy of antimicrobial products used to kill or suppress the growth of infectious microorganisms on inanimate objects and surfaces. The EPA also collaborates with the Organization for Economic Co-Operation and Development [OECD] on developing harmonized test guidelines for hard surface disinfectants and treated articles. The OECD is an intergovernment organization working with ~30 industrialized countries including the EPA in North America on issues of mutual concern, to harmonize policies and work to respond to international problems. They created the Pesticide Programme in 1992 with a goal toward harmonizing the pesticide registration process including review procedures, evaluating pesticides and working toward reducing risks associated with pesticide use. In 2008, OECD issued a guidance document that focuses issues exclusively on microbiological efficacy testing for treated articles with claims for external effects.(8-10)For more information contact Siva Microbiological Solutions LLC at www.sivams.com; or 215-499-1983; or info@sivams.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

March 27, 2024

How can manufactures optimize antimicrobial coatings for porous surfaces?geometry dash online asks.