Tired of Waiting for Paint to Dry?

Figure 1

For all of the advancements in color measurement and management, one challenge still remains: how to accurately measure color for paint and coatings without having the instrument come in contact with the sample. In all phases of color evaluation, waiting for samples to dry, or expending the time and energy to use a drying implement, adds time to specification, development, formulation and quality control processes. In a world where time is money, manufacturers just can’t afford to sit and watch paint dry. Waiting for samples to cure to a measurable condition can take up to 24 hrs. Applying heat to the sample to dry it consumes needless energy and can change the color metrics for certain materials. In addition, production runs may already be underway before dry samples are ready, and this can result in significant amounts of waste and rework before a quality assessment can be completed.

Placing a barrier between the sample and the measurement device isn’t particularly helpful, either, since it can result in changes in appearance (especially gloss) and even color.

Why Measure Wet Paint?

Whether you are manufacturing paint or manufacturing painted items, there are significant benefits to measuring paint while it is still wet. But obviously, wet paint doesn’t look the same as dry paint. To get accurate color readings, it is important to establish standards for both wet and dry paint. Sometimes this is done by the paint manufacturer, with the data being communicated to customers; and sometimes, manufacturers using the paint will need to do this themselves. In either case, manufacturers using paint should always have a process in place to verify the quality and color accuracy of incoming raw materials, including measurement of both wet and dry paint, and coatings samples. Even a small change in ingredients can change the way the color appears.

For example, a paint manufacturer may be using a yellow pigment from a certain supplier. Due to market and other changes, the company decides to move to a different supplier. The pigments are chemically the same, but may be produced using different manufacturing processes. Even something as subtle as this can make a difference in the final appearance of the paint.

In the end, the wet paint measurement is only useful as a shortcut, saving the time and hassle of drying samples. What is most important is the color of the paint after it dries. However, this shortcut can be quite valuable in terms of productivity, and the wet standard only needs to be established once unless there is a significant change in paint formulation.

Establishing Wet and Dry Standards

For manufacturers of paint and painted products alike, then, it is important to not only measure both wet and dry samples, but to establish standards for both. That means applying the wet paint, measuring it, recording the color data and then measuring it again when the sample is dry. This is called establishing an offset. In most cases in this initial stage, we recommend letting the paint dry naturally rather than force drying it, especially if the final product is intended to dry naturally. Using forced-air heat to dry paint risks causing the color to change in a different way than it would change when drying naturally. However, for paints that are meant to be baked on such as automotive paints, samples should be dried using the same baking process. This will typically result in a higher shift in color from wet to dry than drying naturally. The bottom line: use the same drying process that is likely to be applied in the end use. It also goes without saying that separate measurements should be taken for different types of paint, even if they are the same color. For example, separate measurements are required to ensure consistency for gloss finishes, as opposed to eggshell.

It should also be noted that environmental conditions can affect both the color and laydown of the paint, and this should be taken into consideration. Paint and coatings applied in the hot, dry Arizona climate will likely react differently than those same paint and coatings applied in Michigan in the winter.

By following this process, both paint manufacturers and their customers can build reliable databases of wet paint standards that can then be used instead of waiting for samples to dry every time. This will improve productivity, quality and speed to market.

As a cautionary note, this assumes that there are not significant changes over time to the actual raw materials used to make the wet paint that will affect how it dries. Before joining X-Rite, I worked at BASF in the pigment division. We saw cases where, when we changed the way we were producing a given pigment, wet samples would actually switch between being lighter and darker than the dry samples. It is also important to note that changes in raw materials can cause wet color to change even though the dry color stays the same. Thus, with any changes in raw materials, it is important to validate that the wet and dry states still have the same relationship to each other and update standards accordingly.

Standards versus Tolerances

The wet and dry standards we have been discussing are the colors that you actually want to hit. But for most applications, some level of variance is allowed. The tolerance is how closely you must match it for customer acceptance. And the tolerance may be different for wet and dry samples. For example, if I measure a wet sample and there is one unit of difference (whatever measurement metric you use, such as delta E), that might be an acceptable tolerance. If there is a two-unit difference, that could also be acceptable as long as the dry sample meets the minimum variance of one unit. So it is important to establish not only the standard, but also the tolerance, for both wet and dry samples. Both are required for a functional database of standards and to be able to use the wet measurement with confidence.

The Value of Digital Standards

In many cases, the paint manufacturer will provide its customer with data for both wet and dry measurements. This could be in the form of a Certificate of Analysis that is produced at time of manufacture. This may only cover dry measurements, in which case the end customer would need to do their own wet measurement analysis. But a more effective means of data transfer is to provide it digitally. ISO Standard 17972-1:2015 defines an exchange format for color and process control data, as well as the associated metadata necessary for its proper interpretation. While CxF was initially developed by X-Rite for use in the graphic arts industry, the international standard also supports the exchange of color data in other industries.

Across the supply chain, there are many software packages that can both export and import CxF files, such as our Color iMatch formulation and QC software. If your software supports digital standards, this is the best way to go. It ensures accurate communication of the color data and minimizes human error in the color measurement and management process. Metadata should include whether the measurement refers to a wet or a dry sample.

Noncontact Measurement to the Rescue

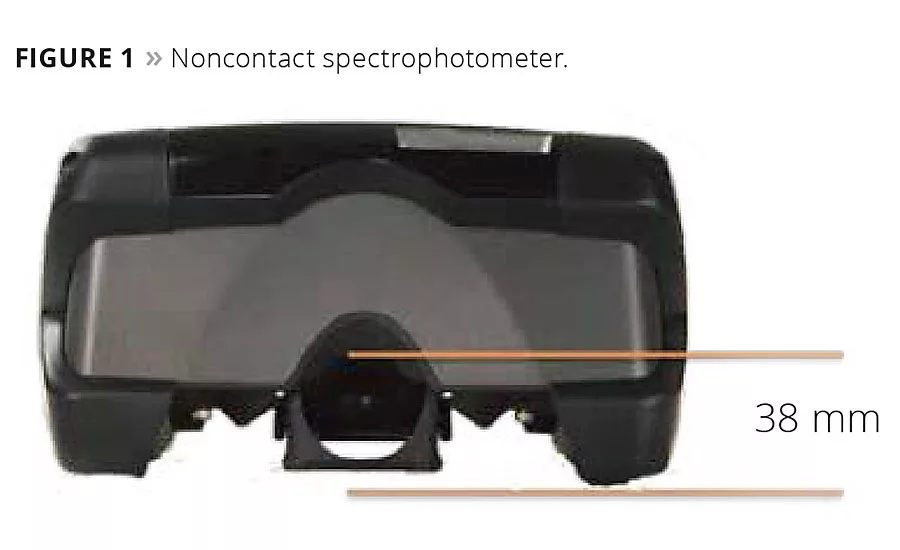

Luckily, today’s hardware and software makes this process easier than ever before. Advances in noncontact color measurement instruments, such as the VS450 45⁰/0⁰ spectrophotometer, allow the fast, accurate capture of wet samples without the worry of contamination of or damage to the instrument. Noncontact spectrophotometers are designed to produce color and gloss measurements for many types of both wet and dry samples without coming into contact with them. Samples do not require any type of protective coating, and the sample is some distance – up to 38 mm in some cases – from the lens of the instrument (Figure 1). This means that the optical system remains free from contamination, reducing instrument maintenance and ensuring its accuracy.

With a noncontact instrument, operators can quickly and easily measure wet and dry flat samples, but they can also measure three-dimensional objects, such as painted furniture on a production line. Using a measurement table or stand compatible with the instrument means that large, bulky and/or irregularly shaped samples can quickly be positioned horizontally or vertically for accurate noncontact measurement. To make the process even better, the data secured from these measurements can be uploaded to computer software for further analysis and for tracking measurement history.

Another important capability in a noncontact spectrophotometer is line-of-sight visibility to the sample to enable operators to quickly and easily position the sample for measurement. Active visual targeting that projects a prominent, illuminated target ring onto the sample also helps secure precise, accurate color measurements, even on patterns.

As with any instrument, it is important to verify that instruments remain within specification. Most manufacturers suggest an annual check-up, much like you might do with your car, to make sure everything is in order. There is also software (such as NetProfiler) that can perform interim assessments of the condition of the instrument, and even provide certification as to the condition of the instrument for audit -purposes.

Case in Point

One paint manufacturer that produces batches of very slow-drying alkyd-based paints used traditional contact-based spectrophotometers for color measurement. It could take the company up to 24 hrs before a product could be approved, slowing down production cycles, or worse yet, risking production of batches that do not conform to the appropriate color specifications.

To address this issue, the company developed a “wet standard” or offset for its products. This is the standard its wet samples need to meet in order to produce a good result in a final dry-to-dry comparison. If the batch meets the wet tolerance test using a noncontact spectrophotometer, packaging can start and the final quality control will be done on dry applications. If the batch is outside the wet tolerance, it can often be corrected before it goes into production. In fact, formulation software can often produce a correction formula that eliminates trial-and-error corrections, saving huge amounts of time and materials. In this way, the paint manufacturer was able to control day-to-day production with a defined standard that saves time, effort and cost.

Conclusion

Waiting for paint to dry is a thing of the past. Best practices for introducing wet standards and wet/dry tolerances include:

- Acquiring a noncontact spectrophotometer and accompanying formulation/QC software to enable measurement and storage of those results in a color database.

- Developing a standard operating procedure (SOP) around the use of wet and dry standards in the paint manufacturing or application process. This includes specifying the drying process to be used for the dry standard as well as acceptable tolerances for both wet and dry samples.

- Ensuring all appropriate staff is trained against the SOP.

- Establishing good quality control procedures for assessing incoming materials, whether they are pigments, resins or formulated paint.

- Exchanging color data in CxF or another acceptable digital format to reduce the opportunity for error.

- Periodically reassessing both wet and dry standards to ensure no significant changes have occurred.

- Ensuring that color measurement instruments are adequately maintained so that they remain in specification, and that all software used in the process is kept up-to-date.

By employing these best practices, your organization can more easily move to the use of wet standards, eliminating the need to wait for paint to dry during the manufacturing process.

Photo courtesy of X-Rite.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!