Polly’s Botched Scale-Up

What was the problem in the scaleup of the acrylic emulsion batch?

Coatings science, whether synthesizing polymers, formulating coatings or applying the paint formulation, always presents many problems and many different ways of approaching those problems. Some can be solved by adding something to fix the problem (the basis for the additives industry). Some can be solved by adjusting the ingredients, and some by looking deeper at the problem in a different way. These are the most elegant and often the best solutions.

The way one solves the problem is based on the person’s background and the perspective they bring to the problem. If the formulator works for an additives company, the solution is another additive. If the formulator works for a resins supplier, the solution is in modification of the resin. Sometimes the formulator reaches for the ingredient that is in front of them on the bench…the hammer that is nearest to their hand.

Formulations often have more ingredients than are needed. A formulator rarely takes something out of the formulation for fear that this is the magic ingredient that holds the whole formulation together. That is why formulations always get longer and more complicated and rarely shorter.

Over time, the formulator learns certain tricks of the trade, fine-tuned calibrations that have worked to solve various problems. But it has always been fascinating to me how completely different approaches can lead to the same solution. There is often no right or wrong answer, just the one that works. Formulating is a science that lends itself to trial and error. It is in the “error” part of the learning where knowledge is gained. After 40 years in the coatings industry, I never stopped learning from these different approaches and my many errors.

I have been fortunate in my career to work with many good formulators, polymer chemists and application scientists. I have also spent most of my career interfacing with customers. On occasion, the products did not work the way needed or expected, which caused problems for customers and new opportunities for the products. I always learned from hearing about these problems and opportunities.

This column is my way of sharing some of this knowledge, but also a way for me to learn even more. I have been in the middle of, or sometimes, the cause of, some huge formulating fiascos. I have learned much from solving these problems, or more often learned from the advice and assistance I have received in solving them.

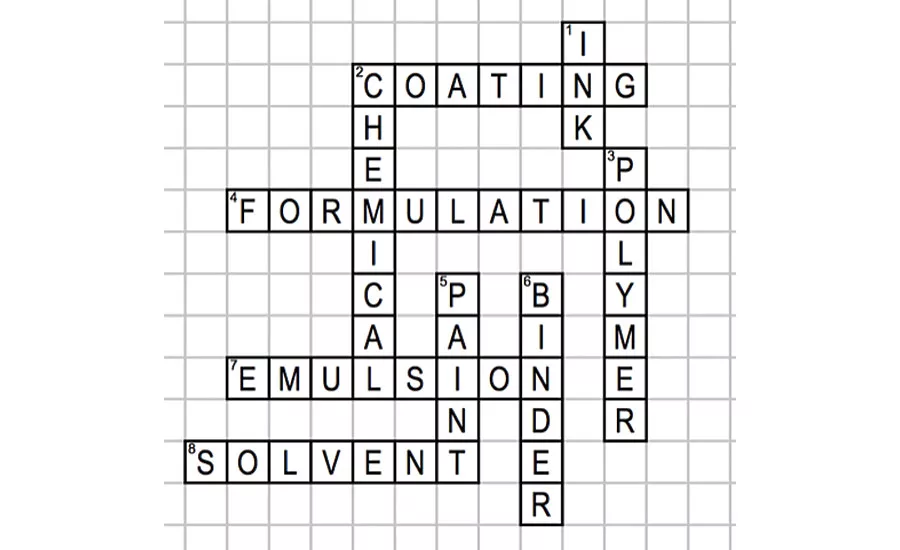

The problems in this column will be of three general types based on my experience in the industry and the three different types of coatings problems most commonly encountered. The problems will be presented by three primary individuals representing each of these three types of problems. All the characters work at the fictional paint manufacturer, Big Time Paint Co.

Polly Mertz is a young Ph.D. polymer synthesis chemist developing new resins for Big Time Paint. She has only been in the job for a couple of years.

Saul Vance is the formulating chemist. Saul has been in the industry for over 20 years, and formulates all different types of coatings systems for Big Time Paint.

Lindsay Doyle is the technical service and application chemist responsible for testing the formulations under conditions used by the customers of Big Time. She interfaces with the customers that often experience problems in applying the coatings. She works with the customer to come up with a solution that is amenable both to the customer and to the company.

Lastly, Al Kidd is the old timer, the experienced technician that has seen it all. He is the glue that holds Big Time Paint Co. together, and the guy behind the scenes that gets the paint made on time and in spec. Al also helps the three persons above in solving the problems.

The column is my take on a problem and how it was solved, but mine is not the only correct answer and may not be the best answer. I want to encourage others to submit their solutions to these scenarios.

In a following month after the scenario has been outlined, I will present my solution, but also highlight solutions submitted by others. I hope that readers will present their own ideas of how to solve the problems presented. This column should be interactive and present different ways to solve the problem. In this way, the column may teach different ways of solving a problem based on different perspectives and different experiences from the readers. You can submit your ideas and answers directly to me at keithmmoody@aol.com, or directly on the article’s comments section below.

It is my hope that the articles will be both educational and entertaining. I hope the readers identify with at least one, but hopefully all, of the characters presenting and solving the problems. And I hope we all have some fun. Here is the first conundrum.

Polly’s Botched Scale-Up

A good resin chemist keeps the resin in the reactor. The young chemist, Polly Mertz, didn’t learn this in graduate school, but had heard it many times from her mentor, Al Kidd, at Big Time Paint Co. since joining the company just two years earlier. Just like the good truck driver always keeps his truck between the ditches, a good resin chemist makes sure the resin stays in the kettle, both in the lab and especially, in the plant.

Polly had just returned from the Waterborne Conference in New Orleans and was eager to oversee her first scale-up of a new emulsion polymer. This was not only her first scale-up of a formulation she had developed, it was the first scale-up using this reactor to produce a redox catalyzed emulsion acrylic polymer. The all-stainless-steel reactor had been equipped with low-shear mixing very similar to her lab setup. However, the engineering team wasn’t able to get the two separate redox feed tanks and lines installed and connected through the top of the 500-gallon reactor in time for the scale-up run.

That morning she was surprised to learn that the instructions she had left before leaving for the conference, for the engineering department to connect the two needed feed tanks for the separate aqueous redox systems to the large reactor, had not been followed. The two systems had to be pumped simultaneously into the reactor along with the acrylic pre-emulsion from the stainless steel feed tank.

The formulation was very simple:

- Deionized water

- Acrylic monomers, including acrylic acid, butyl acrylate and methyl methacrylate

- Surfactant mixture

- Redox system made up of an aqueous reducing agent and an aqueous oxidizing agent…thus the term “redox” used for the catalyst system.

Polly knew it wasn’t exactly standard protocol to run one of the redox solutions from the large polyethylene tank through plastic tubing into an open loading hatch to the reaction below. On the other hand, the reaction was in water, was very low temperature, and only generated a few degrees temperature of exotherm at the start of the acrylic polymerization. Even though the manhole cover wasn’t bolted securely, the heavy cover on the hatch and the exhaust vent above the opening kept most of the vapors escaping from the reactor off the manufacturing floor. She made sure that the aqueous redox solution was flowing through the tubing and that the tube wasn’t pinched closed by the weight of the heavy lid.

The other redox solution was running through the new lines recently installed by maintenance just prior to her returning from her trip. Since there was some urgency in getting this new batch made for the customer, the maintenance group had pulled parts off an old alkyd reactor no longer in service rather than ordering new steel connections.

Polly had made the acrylic latex many times in the lab using the same raw materials as they were planning to use in the first plant run. She had even gotten the water she used for the lab batch from the plant after checking the quality of the deionized water system. She had ordered the acrylic monomers and the two-part redox system for the 500-gallon batch before she left for the conference. Each time she had made the formulation in the lab, the redox feed had generated only a very slight exotherm of a few degrees, and the polymerization had proceeded gradually, controlled by the feed rate of the monomer and the two redox solutions. The polymerization took place in the lab well below the boiling point of water.

That morning, as she made her way up the stairs in front of the building to check on the progress of the batch, she thought of how well the loading had gone earlier in the day. As she turned from the stairwell and walked onto the manufacturing floor where the reactor stood, she saw a hot white column rise out of the reactor man-way like a solid living white snake, shiny and steamy, three feet thick and rising a full 15 feet above the plant floor before crashing into the floor and forming a frothy, thick, steaming layer of hot polymer of white cottage-cheese-like consistency three inches thick for as far as she could see between the two reactors. The reacting acrylic monomers had exothermed to the point of boiling the water, and over half of the contents of the reactor were now all over the plant floor. The smell was very acrid, from the acrylic acid in the formulation, and made her sick to her stomach.

Later, after the two-day cleanup, Polly sat in the lab trying to determine what had botched her reaction. Something in the scale-up had gone terribly wrong, and she needed to find the problem before trying the scale-up again. As she sat going over all the details of the preparations she had made for the batch, Al came into the office and told her that he thought he knew how to find the problem. Knowing that she had returned from New Orleans only a week earlier, he asked, “Do you still have your badge from the Waterborne Symposium?” He hurried out of the office with the badge and was back in 15 minutes with the answer to the problem.

Why did he take the badge? What was the problem in the scale-up of the acrylic emulsion batch? E-mail your ideas and answers to Keith Moody at keithmmoody@aol.com, or comment directly in the comment section below.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!