New Bio-Based Solvent Supports Quest for Safer and More Sustainable Coatings

Increasing pressure from governments and consumers demanding safer and higher-performance materials is impacting all industries, and the paint and coatings sector is no exception. With a wide range of users – from closed production units through to amateur DIY customers and many combinations in between – the industry is uniquely exposed to concerns and demands to reduce toxicity and carbon footprints – yet there are no easy answers.

In response to this need, Australian biotechnology company Circa Group has developed a realistic alternative to increasingly regulated and more toxic solvents, in partnership with the Green Chemistry Centre of Excellence at the University of York in the U.K. Cyrene™ (CAS 53716-82-8) is a new solvent with similar solubilizing properties to traditional dipolar aprotic solvents such as N-methyl-pyrrolidone (NMP) and N,N-dimethylformamide (DMF).

The solvent is produced in two steps from waste sawdust (via chemical building block levoglucosenone) at Circa’s FC5 prototype plant in Tasmania, Australia. This plant, built as part of a joint venture with Norwegian pulp and paper company Norske Skog, is now online and producing a regular supply of 99% pure Cyrene.

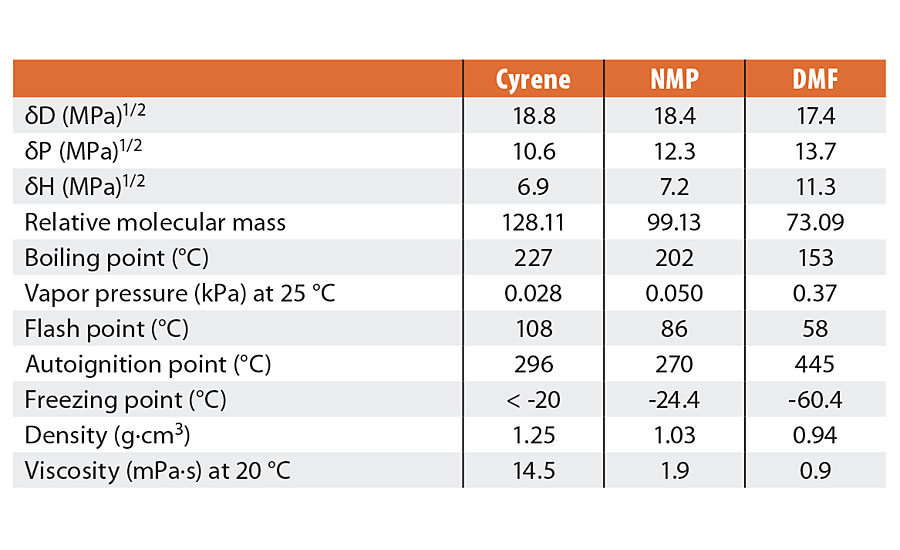

As illustrated in Table 1, the Hansen solubility parameters related to dispersion (dD), polar (dP) and hydrogen bonding (dH) interactions for Cyrene are a close match to NMP and DMF, indicating that it has a comparable solvency power. Like NMP, DMF and other traditional dipolar aprotic solvents, the new solvent is miscible in water and has high flash and boiling points as well as low vapor pressure. Importantly, Cyrene does not contain any nitrogen or sulphur heteroatoms typically present in polar aprotic solvents.

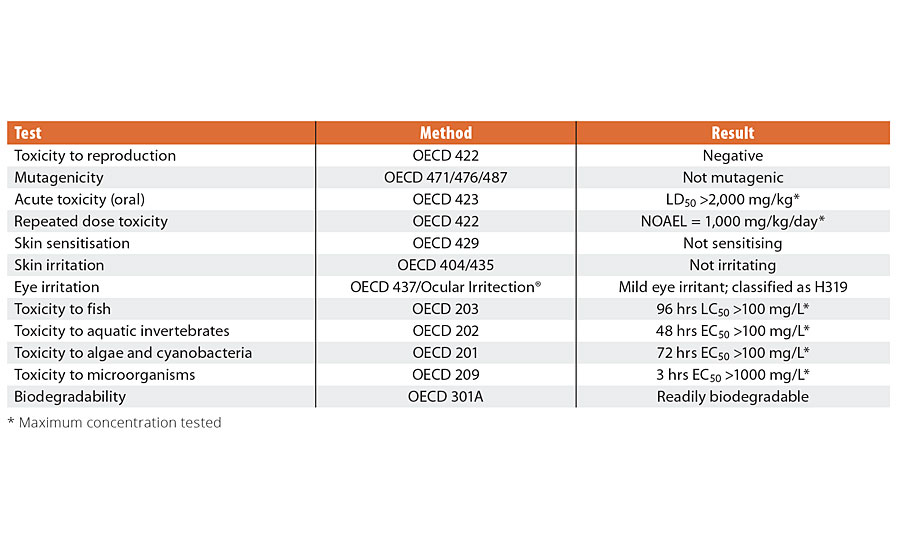

As well as having a unique property set, including high viscosity, surface tension and aprotic polarity, the solvent is also a safer and more sustainable alternative to traditional solvents. It has been shown to be readily biodegradable and exhibits an improved Health, Environment and Safety (HES) profile compared to NMP and DMF. A summary of its HES profile is provided in Table 2.

Crucially, Cyrene is not classified as reprotoxic, unlike NMP, DMF and dimethylacetamide (DMAc), which are on the candidate list of the EU’s Substances of Very High Concern (SVHC) due to their reprotoxicity. A new NMP restriction was also recently adopted, meaning that after May 2020 its use will be further regulated and it will not be able to be manufactured or used in the EU unless operational conditions are maintained to ensure that exposure to workers is below specified levels.1

In addition, Cyrene has a >98% bio-based content (based on all atoms, including hydrogen), being derived from a certified and renewable waste source – sawdust – unlike the vast majority of dipolar aprotic solvents, which are derived from fossil-based resources. An independent life-cycle analysis has also shown that production of the solvent using Circa’s process is heading towards being greenhouse gas neutral.2

Circa has recently been granted authorization by the European Chemicals Agency (ECHA) to manufacture or import up to 100 tonnes/year of Cyrene in the European Union, after receiving REACH Annex VIII approval.

Applications

Initial interest in the product revolved around reaction chemistries where the polar aprotic class of solvents are already widely applied (i.e. as a processing solvent in the pharmaceuticals industry).3-4

More recently, research carried out by academic groups and industry across the world have shown that the solvent could also be a suitable alternative for NMP and DMF in the production and dispersion of polymers used in the coatings industry.

For example, Cyrene has been successfully applied in the production of polyamideimides (PAIs), which are used in a wide range of applications including the production of electrical wire insulation (wire enamel). Both the polymerization and curing of this polymer can be done using the new solvent. Additionally, patent WO2017050541 states that the application of Cyrene instead of NMP as a solvent for the polycondensation of carboxylic acid anhydrides and diisocyanates not only facilitates rapid curing but also provides coatings with enhanced solvent resistance.5

Other polymers and polymer systems routinely used in the paint and coatings sector have been shown to dissolve in Cyrene, and the results of these trials are expected to be published shortly in peer-reviewed scientific papers. In the meantime, a recent publication by Fei et al. demonstrated that the solvent is able to dissolve, to some degree, polymers such as polyimide (PI), polyacrylonitrile (PAN), polysulfone (PSf), polyvinylidene difluoride (PVDF), polybenzimidazole (PBI) and polydimethylsiloxane (PDMS).6 Furthermore, HSPiP modeling carried out by Abbott suggests that a 55:45 blend of anisole:Cyrene is a near-perfect match for the dissolution of bio-based polymer polylactic acid (PLA).7

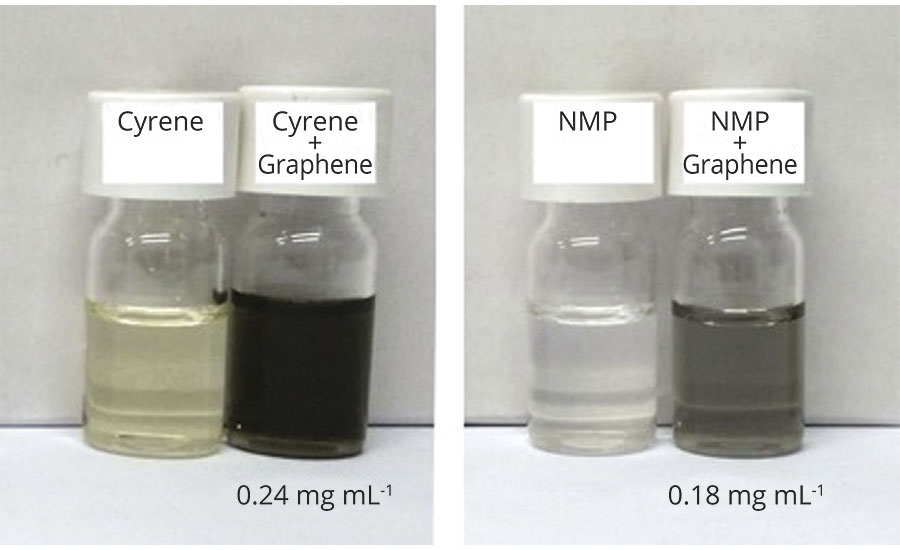

In addition, it has been shown to have near-ideal physical properties for the exfoliation of graphite and, crucially, the production of stable, high-concentration graphene dispersions and inks.8-9

A joint study by the University of York and the Spanish National Research Council (CSIC) demonstrated that a 13-fold increase in graphene loading could be achieved by switching from NMP (the solvent of choice) to Cyrene (Figure 1). In addition, graphene produced in Cyrene was of significantly higher quality, with 93% of flakes comprising of 10 layers or less, as well as having a greater aspect ratio and much lower edge defects. It is believed that the solvent’s relatively high viscosity (14.5 mPa.s at 20 °C vs 1.9 mPa.s for NMP) both improves the stability of graphene dispersions by reducing settling velocity under centrifugation, according to Stokes’ law, and helps to preserve the integrity of the graphene flakes.

As graphene is being increasingly incorporated into coatings and materials to enhance performance (e.g. heat and thermal conductivity, increasing chemical resistance, anti-microbial performance and reduce fouling), Circa and its customers continue to explore the solvent’s unique properties, which could potentially be used to incorporate greater concentrations of other (solid) additives.10

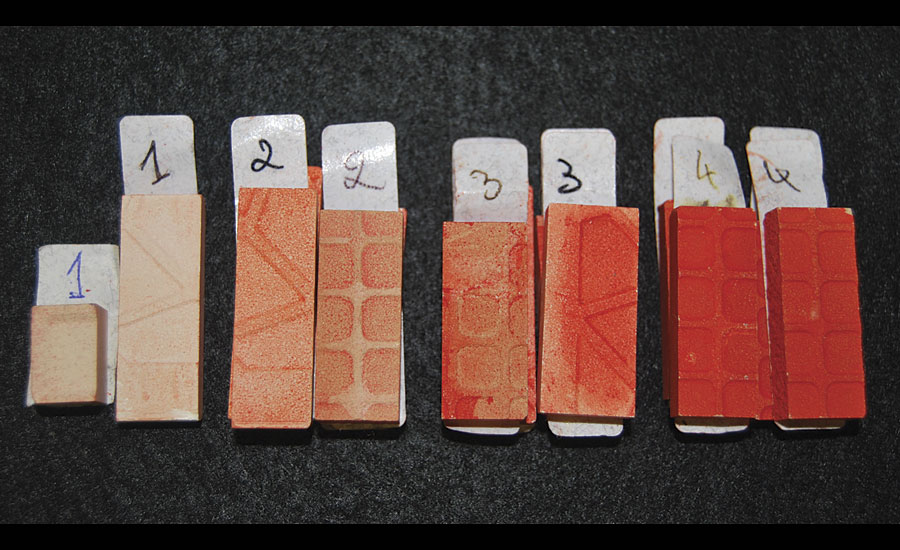

Lastly, an as-yet unpublished study by the University of York has investigated the use of Cyrene in the removal of common paints (paint stripper) and graffiti from various porous materials. An extensive range of solvents was tested as part of a project supported by the UK innovation agency. As illustrated in Figure 2, the solvent was able to successfully clean the materials tested in this study and compared favorably against commonly used solvents for this specific application.

Conclusion

For companies looking for high-performance, non-toxic, sustainably produced solvents, a new bio-based solution offers a safer and high-performing alternative to the toxic dipolar aprotic solvents traditionally used in the paint and coatings industry.

With its FC5 prototype plant now online, commercial quantities of Cyrene are available for product testing worldwide through Circa’s distributors Will&Co and Merck KGaA, which operates as MilliporeSigma in the U.S. and Canada and sold under the Sigma-Aldrich brand.

The positive market feedback on the product’s performance over the last year has provided the foundation Circa and its partners needed to move forward with feasibility studies into FC6 – a larger, commercial-scale plant.

References

1 https://echa.europa.eu/substances-restricted-under-reach/-/dislist/details/0b0236e1827f617f.

2 Mellentine, Turning Lignocellulose Waste into Solvent with Lower Carbon Footprint, American Chemical Society (ACS) National Meeting & Exposition in Philadelphia, Pennsylvania, August 21-25.

3 Wilson et al., Cyrene as a Bio-Based Solvent for HATU Mediated Amide Coupling, Org. Biomol. Chem., 2018,16, 2851-2854.

4 Wilson et al., Cyrene as a Bio-Based Solvent for the Suzuki–Miyaura Cross-Coupling, Synlett, 2018; 29(05): 650-654

5 Wedmann, Preparation of Polyamidoimides, WO2017050541.

6 Fei et al., Tailoring the Performance of Organic Solvent Nanofiltration Membranes with Biophenol Coatings, Mendeley Data, 2019, v1.

7 Abbott, Solubility Science: Principles and Practice, 2018. https://www.stevenabbott.co.uk/practical-solubility/the-book.php.

8 Salavagione et al., Identification of High-Performance Solvents for the Sustainable Processing of Graphene, Green Chem., 2017, 19, 2550-2560.

9 Pan et al., Sustainable Production of Highly Conductive Multilayer Graphene Ink for Wireless Connectivity and IoT Application, Nature Communications, 2018, 9, 5197.

10 Nine et al., Graphene: a Multipurpose Material for Protective Coatings, J. Mater. Chem. A, 2015, 3, 12580-12602

11 Sherwood et al., Dihydrolevoglucosenone (Cyrene) as a Bio-Based Alternative for Dipolar Aprotic Solvents, Chem. Commun., 2014, 50, 9650.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1741213707&width=200)