Achieving Water Authority Compliance with Automated Wastewater Treatment

Industrial facilities must meet EPA and local wastewater requirements for effluent, including those under the Clean Water Act. Failing to do so can result in severe fines that quickly escalate.

Although the type of industry and specific operational practices determine the type of wastewater generated, most involve suspended solids, heavy metals, organic compounds or a variety of other pollutants. Under the Clean Water Act, for example, the EPA has identified 65 pollutants and classes of pollutants as “toxic pollutants,” of which 126 specific substances have been designated “priority” toxic pollutants.

For many facilities, this means installing a wastewater treatment system that effectively separates the contaminants from the water so it can be legally discharged into sewer systems or even re-used. However, traditional wastewater treatment systems can be complex, often requiring multiple steps, a variety of chemicals and a considerable amount of labor. Even when the process is supposedly automated, too often technicians must still monitor the equipment in person. This usually requires oversight of mixing and separation, adding of chemicals, and other tasks required to keep the process moving. Even then, the water produced can still fall below mandated requirements.

Although paying to have industrial wastewater hauled away is also an option, it is extraordinarily expensive. In contrast, it is much more cost effective to treat the industrial wastewater at its source, so treated effluent can go into a sewer, and treated sludge passes a TCLP (Toxicity Characteristics Leaching Procedure) test and can be disposed of as non-hazardous waste in a local landfill.

Fortunately, complying with EPA and local wastewater regulations has become much easier with more fully automated wastewater treatment systems. Such systems not only reliably meet regulatory wastewater requirements, but also significantly reduce the cost of treatment, labor and disposal when the proper separating agents are also used.

Cost-Effective, Automated Wastewater Treatment

In contrast to labor-intensive, multiple-step processes, automated wastewater treatment can help to streamline production, usually with a one-step process, while lowering costs at industrial facilities.

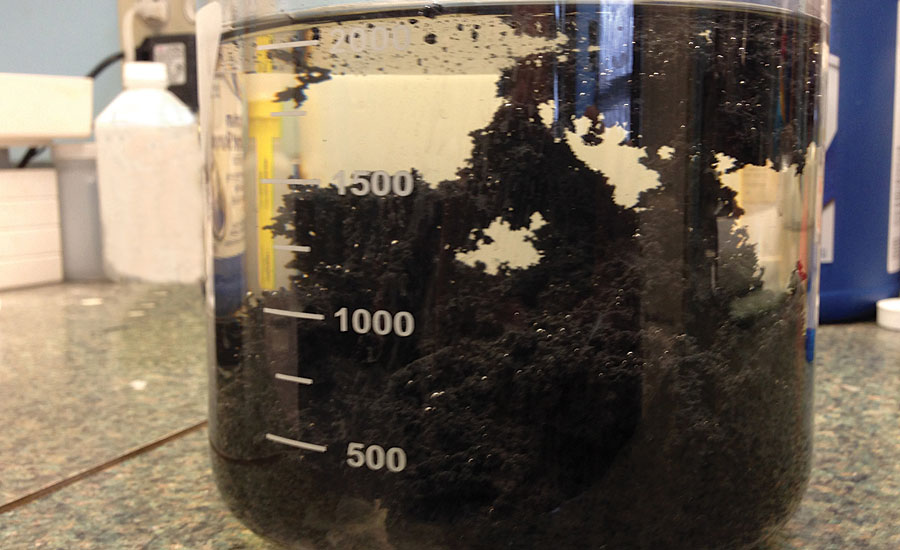

An automated wastewater treatment system can eliminate the need to monitor equipment in person while complying with EPA and locally mandated requirements (Figure 1). Such automated systems separate suspended solids, emulsified oil and heavy metals, and encapsulate the contaminants, producing an easily de-waterable sludge in minutes. The water is typically then separated using a de-watering table or bag filters before it is discharged into sewer systems or further filtered for re-use as process water. Other options for de-watering include using a filter press or rotary drum vacuum. The resulting solids are non-leachable and are considered non-hazardous, so will pass all required testing.

These systems are available as manual batch processors, semi-automatic or automatic, and can be designed as a closed-loop system for water reuse or provide a legally dischargeable effluent suitable for the sewer system. A new, fully customized system is not always required. In many cases, it can be faster and more cost effective to add to or modify an industrial facility’s current wastewater treatment system when this is feasible.

However, because every wastewater stream is unique to its industry and application, each wastewater treatment solution must be suited to or specifically tailored to the application. The first step in evaluating the potential cost savings and effectiveness of a new system is to sample the wastewater to determine its chemical make-up followed by a full review of local water authority requirements. The volume of wastewater that will be treated is also analyzed to determine if a batch unit or flow-through system is required. Other considerations include the size restrictions so the system fits within the facility’s available footprint.

An example of successful automated wastewater treatment involves one of the largest independent corrugated manufacturers, which processes over 8 million sq. ft. of corrugated packaging and displays per day. The corrugated manufacturer required more efficient treatment of wastewater that is generated from the washdown of its flexographic printing presses that use various inks in the manufacturing process.

For this, the corrugated manufacturer turned to an EconoFlow fully automated wastewater system as well as -Cleartreat ® separating agent from Sabo Industrial Corp., a New York-based manufacturer, distributor and integrator of industrial waste treatment equipment and solutions, including batch and fully automated systems, Cleartreat separating agents, bag filters, and accessories.

The system included a high-volume flow-through mix unit, large-capacity feed hopper, bag housing for solids removal, self-indexing dewatering table, and final polishing vessels. Sensors ensure proper material flow and operation, and onscreen audio-visual alerts indicate if anything requires attention.

However, instead of typical labor-intensive, in-person monitoring of equipment to correct a problem, the mix chambers’ motors are controlled electronically by Human Machine Interface (HMI) and can be remotely adjusted, along with the mix motor speed, and powder feed by Sabo Industrial. The industrial wastewater equipment provider can utilize the equipment’s integrated webcams as needed to view the mixing chambers for flocculant formation, floc structure, color and water clarity. Remote access also enables viewing alert conditions on the touchscreen and provides the ability to reset the machine, if needed.

Separating Agents

Despite all the advances in automating wastewater treatment equipment, any such system requires effective separating agents that agglomerate with the solids in the wastewater so the solids can be safely and effectively separated out (Figure 2).

Because of the importance of separating agents for wastewater treatment, Sabo Industrial uses a special type of bentonite clay in a line of wastewater treatment chemicals called ClearTreat. This line of wastewater treatment chemicals is formulated to break oil and water emulsion, provide heavy metal removal, and promote flocculation, agglomeration and suspended solids removal.

Bentonite has a large specific surface area with a net negative charge that makes it a particularly effective adsorbent and ion exchange for wastewater treatment applications to remove heavy metals, organic pollutants, nutrients, etc. As such, bentonite is essential to effectively encapsulate the materials. This can usually be achieved in one-step treatment, which lowers process and disposal costs.

In contrast, polymer-based products do not encapsulate the toxins, so systems that use that type of separating agent are more prone to having waste products leach back out over time or upon further agitation.

In the case of a heavy equipment dealer with six locations in New York and Connecticut, an EconoFlow wastewater treatment system using a bentonite-based ClearTreat formulation was required for wastewater created by equipment washdowns. The wastewater contained oil, grease, suspended solids, heavy metals and cleaning agents.

For the application, Sabo Industrial supplied an EconoFlow 10-gallon per minute unit, which included a 24-bag filter tank, a single-stage bag filter housing, final polishing vessels, and an 850-gallon storage tank for water reuse. The system also has HMI capabilities that allow remote monitoring and adjustment of the equipment as needed. The system provides reliable, one-step wastewater treatment, and legally dischargeable or reusable effluent.

Conclusion

Today’s automated systems along with the most effective separating agents can provide manufacturers with an easy, cost-effective alternative so they remain compliant with local ordinances and the EPA. Although there is a cost to these systems, they do not require much attention and can easily be more economical than paying fines or hauling.

For more information, call 845-562-5751 or visit http://saboindustrial.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!