New Pigment Dispersions Solve Incompatibility and Inconsistency Problems

in Solvent-Based Industrial Coatings

Most coatings formulators agree that the available options of solvent-based pigment dispersions have trouble meeting the industry's coloristic standards for tint strength and shade largely due to either incompatibility or poor batch-to-batch consistency of the colorant. These problems are especially evident when formulating high-performance industrial coatings, where achieving consistent and repeatable tinting with older colorant palettes in newer resin chemistries can be particularly challenging. With this in mind, Clariant initiated a research project three years ago to engineer a new range of colorants that meet the established coloristic standards needed for industrial coatings, as well as deliver the enhanced color performance the industry has been seeking. Combining direct customer feedback and statistical modeling with our long-standing expertise in organic pigments, Clariant utilized our global network of chemists and product experts to drive the development of a better colorant solution for use in industrial coatings.

“What we discovered after talking with a lot of paint manufacturers was that the current available dispersions for industrial coatings had very wide tint strength tolerances. Especially in the point-of-sale business, some shops could spend several hours tweaking formulations to arrive at a good color match for their customers. This kind of variability can easily add to the overall cost to serve the customer if you consider not just the extra material costs, but the lab hours to arrive at the desired shade,” states Dr. Romesh Kumar, Sr. Technical Sales Manager at Clariant North America.

In addition to the batch-to-batch tint strength variability of pigment dispersions, the team at Clariant also quickly learned the difficulties coatings manufacturers encounter when transferring color recipes from one resin chemistry to another. Dr. Kumar continues, “With some of the new requirements in higher performing industrial coatings (weather fastness, opacity, and higher chroma red, yellow and orange shades) it is a real challenge to adapt older color dispersions to meet these challenges.”

Equipped with the knowledge gained from coatings formulators, Clariant began development of a next generation of pigment dispersions aimed at overcoming these key challenges. The team diligently screened the latest resin technologies, and painstakingly evaluated a multitude of advanced additive packages and different solvent options through countless hours of research and testing. The goal was clear — design a new range of colorants with stricter batch-to-batch consistency and an improved ability to replicate color recipes across different base chemistries. However, the new range should also adhere to the industry standards for coloristic properties, such as shade and tint strength, to be considered a coloristic drop-in for existing coatings formulations.

Color Inconsistency — Not All Colorants Are Created Equal

One of the most challenging tasks when tinting industrial coatings involves using an established set of colorants to reproduce an industry-standard shade (e.g. RAL or OSHA) to create a custom color, or to simply match a competitor’s existing shade. In all cases, using high-tint-strength variation colorants to reproduce a specific shade can be a costly process. In general, the most common causes of color inconsistency can be attributed to one (or more) of the following characteristics:

-

The quality and chemistry of the pigment(s) used in the dispersion;

-

The stability of the liquid master standard;

-

The repeatability of the actual paint tinting process.

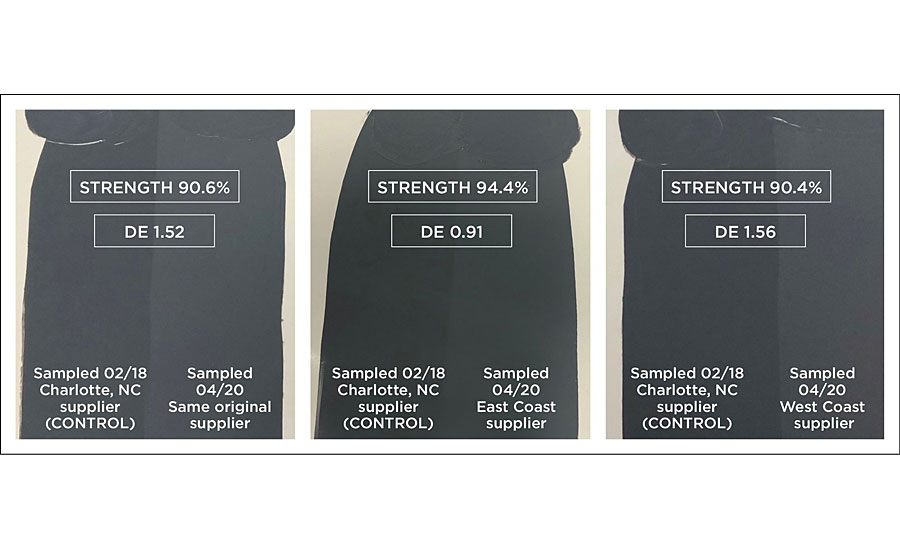

Without strict control over the manufacturing, processing or in some cases the sourcing of the base pigments, the dispersion will only be as good as the pigments used. Without this level of control, tinters will be forced to spend additional time (and money) fine tuning a normally reproducible recipe for their customers (Figure 1).

“Our early development work took us down the path of analyzing what was already available to the market to determine what level of quality had been typically ‘accepted’ by formulators. From there it became clear there were some fairly wide tint strength tolerances in the market, and if we could close those gaps, in other words, improve the batch consistency, our customers would have a far easier time replicating color shades and speed the delivery to their customers,” says Andreas Harz, Head of Dispersions for the Americas at Clariant.

“Another issue that we learned about from our customer research was related to color flocculation, which occurs when a tinted coating actually changes shade significantly between the application and drying processes,” Harz continues.

To identify and quantify these problems, Clariant examined the different pigment dispersions available in the market in standard resin bases. The rigorous evaluation protocol included rub-up and shake-out tests, visual inspection of colorant stability and flocculation. The test films were prepared by brush, roller and sprayer applications to simulate real-world application processes.

This early testing was mainly to assess the current level of performance in the marketplace and served to ensure uniformity in the development of new colorants. As an example, multiple drawdowns of tinted industrial coatings were made, and the films were allowed to set, but not dry. Then by gently rubbing the films, the color differences were compared and quantified once the films had completely dried. It was apparent that by rubbing the films, additional shear was introduced into the wet coating, which caused the colorant to be more thoroughly dispersed and resulted in a color shift in the film, a condition not unlike combining a brush and roller during typical application (Figure 2).

Ordinarily, this may not be a serious problem, depending on the application method or if there is a low likelihood that surface touch-ups are required. However, in the field, this problem could easily manifest if the surface is coated using a combination of spray, brush and/or roller. In practice, this scenario is quite common, such as painting a storage tank or bridge. By contrast, coating in a controlled environment such as a step in a larger manufacturing process or in a fabrication shop most likely would not require multiple application methods. When recoating in the field, however, the applicator might coat certain tight, restricted areas or surface irregularities using a brush and then follow up using a roller on the larger and smoother surfaces.

The effect of batch-to-batch variation in tint strength of colorants is easily observed when a formulation is tinted and subsequently shaken with a mechanical paint mixer or an agitator. With a small variation, the final color is relatively consistent to the desired color. However, when the tint strength variation is large, the final color will vary across tinted batches of the coating, and will require time-consuming adjustments and could compromise the performance of the coating. Ideally, the coating should be correctly tinted by using a desired tint formula and then processing on a mechanical shaker for a reasonable period, rendering the colorant efficiently and completely dispersed into the coating. For example, consider a standard enamel of approximately 90 KU viscosity packaged in a suitable container with at least 3% headspace. After tinting it is reasonable to expect the coating and colorant to be completely homogenized after approximately 3 min on a mechanical shaker. However, in some circumstances it is easily demonstrated that the final shade of the tinted coating product can change the longer the coating is agitated. This can present challenges to both the tinter and the applicator as well when color uniformity across multiple containers cannot be guaranteed.

“It's not unusual to see 10 individual containers of the base coating tinted with the same batch of colorants and find that after tinting, there is a visual difference in the final shade of all 10 containers. “Boxing” of multiple pails of material (mixing all 10 containers together at the job site) may provide a temporary solution, however it doesn’t address the root cause, and though it results in a uniform shade, it’s still not accurate to the original shade the customer ordered,” says Harz.

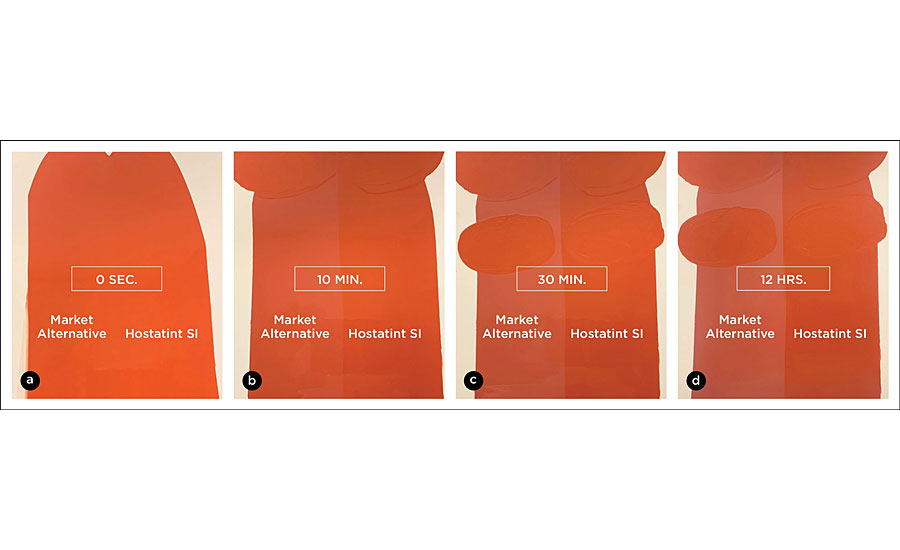

Incompatibility Challenges — Getting the Additives Package Correct

Another common issue is incompatibility of the pigment dispersion in paints. In other words, the colorants do not properly mix into the paint due to flocculation and or separation. More simply termed, the colorant "floats," meaning the colorant is rejected by the paint system. This condition is often apparent within 10 to 15 minutes after the paint system is tinted and homogenized. Small streaks or blemishes may begin to appear on the surface of the wet paint in the pail, and as the paint sits, more colorant will float to the surface. Large-scale paint manufacturing is susceptible to color float as well. When the paint is tinted and mixed prior to packaging, color streaks may be visible emanating from the paint vessel walls and trailing into the vortex created by the mixing blade. In more severe cases, blemishes or what appears to be small “stars” of rejected colorant can be seen throughout the dried paint film. In such cases, color float can add frustration for an applicator since the color of the coating can vary throughout the application process. Further, any touch-ups later to match the original dried color or blend back into previously painted surfaces to achieve a uniform finish will be more challenging (Figure 3).

Applying the latest “Design of Experiment” concepts, Clariant devised a systematic method to evaluate over 25 different additives for solvent-based pigment dispersions. These techniques helped expedite the evaluation of the multiple variables in their initial formulating trials and significantly narrowed the focus of which additive package would deliver the ideal solution. After a multitude of iterations and lab trials, a combination of different additives was identified as the optimal blend to formulate pigment dispersions with consistent tint strength and maximum compatibility across the widest range of industry-standard resin systems.

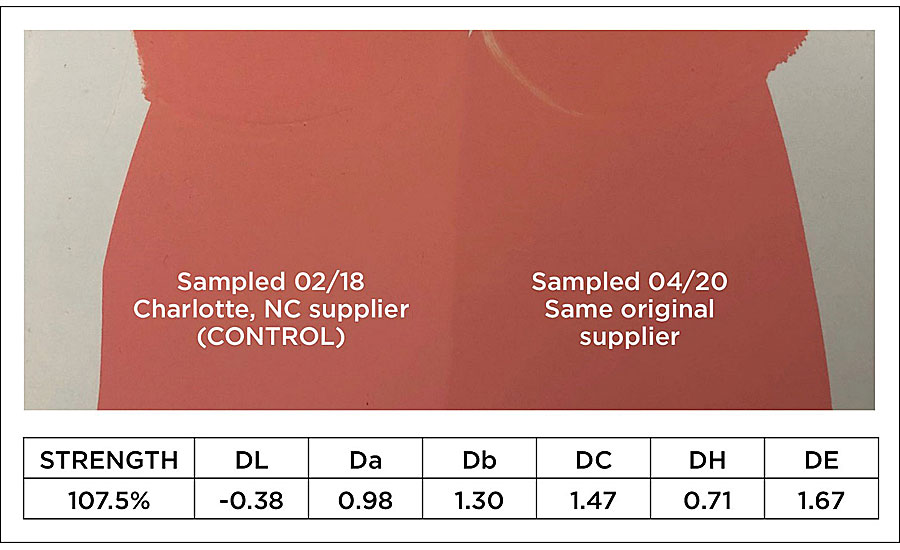

The process also helped to identify another key issue related to flocculation in solventborne paints. Over a very short period, the shade of the test samples changed significantly, even without additional agitation. As shown in Figure 3, a test conducted on a market-alternative red iron oxide dispersion, the color shifts rapidly over a 30-min interval. Introducing additional shear redistributes the pigment dispersion into the coating, however, the portion of the drawdown that is left undisturbed continues to fade as the film dries. This presented another challenge for Clariant to consider, knowing that most application processes likely include scenarios where a coating is applied, for example, by a roller and then followed up with a brush. In the field, this could result in a “hat-banding” effect where there is a noticeable difference in color between the borders and the interior of a painted surface. Using the findings from our research, Clariant incorporated this criterion into our requirements for evaluating the different additives and found a solution (Figure 4).

For Clariant, this innovative approach to product development resulted in a new range of pigment dispersions with improved batch consistency for tint strength and improved compatibility across a broader range of resin systems, as well as a coloristic drop-in to the industry standards.

Hostatint SI – A Value-Based Solution

After extensive research and testing, in June 2020, Hostatint SI was introduced as the next generation in solvent-based universal colorants. Designed to match current industry color standards and engineered for improved tint strength, color acceptance and more consistent performance, Hostatint SI is suitable for both manual and automatic dispensing equipment for industrial in-plant tinting or point-of-sale applications. Hostatint SI manufacturing is carefully controlled in a newly constructed, state-of-the-art facility equipped with dedicated horizontal media mills, automated metering equipment, and a team of experienced operators and technical staff capable of ensuring product performance and consistency.

As a result of the controlled rheology, exceptional and efficient pigment grinding and thorough quality control during manufacturing, the consistent tint strength of Hostatint SI allows for accurate and repeatable color dosing, making it the ideal product for point-of-sale applications. Hostatint SI is available in a variety of packaging for in-plant tinting to simplify manufacturing and expedite tinted coatings direct to end customers.

Hostatint SI is compatible with a wide variety of technologies employed in solvent-based industrial and architectural coatings, and will eliminate or minimize rub-ups, color flocculation, kickouts and other detrimental behaviors observed when introducing colorants into paint bases.

For additional information or to obtain product samples, contact a local Clariant sales representative or a Clariant authorized distributor (Lintech International in the U.S., or Brenntag in Canada). Or click here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!