Selective Brush Plating: a Flexible, Automated Solution to Plating Challenges

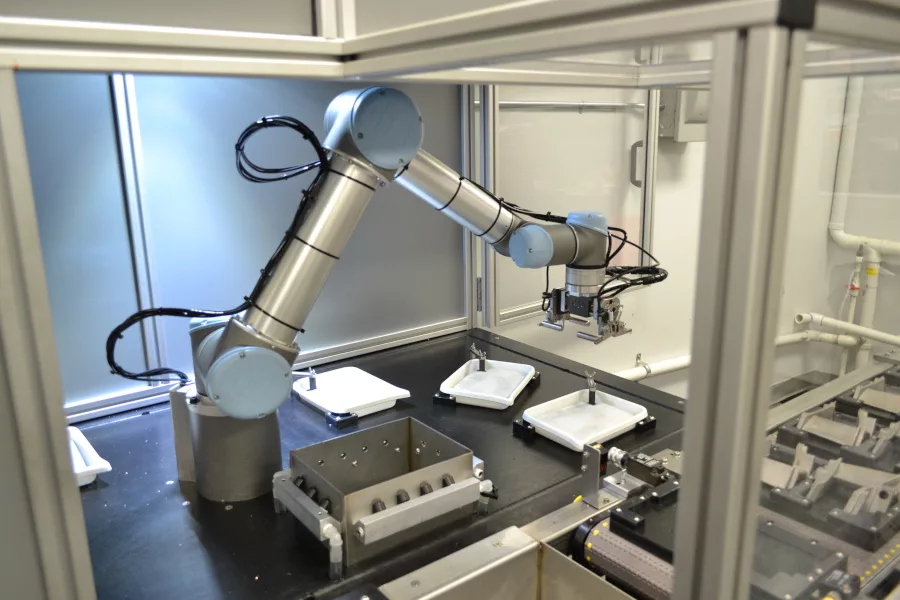

Image courtesy of SIFCO

Image courtesy of SIFCO

In-service failure of equipment and components cannot be tolerated, and intervals between required maintenance should, ideally, be extended as far as possible. Depending on the environment in which components will operate, a particular type and thickness of electroplated metal deposit can be applied to protect against corrosion from chemicals, vibration and wear, moisture ingress, and temperature extremes.

When a component reaches the final surface treatment stage, significant time and money will already have been invested in processing it, which can be important depending on the application involved. Meanwhile, components being repaired or refurbished may have significant life left in them and it is vital that their full value be extracted. Ensuring optimum performance in plating, especially the repair and refurbishment of components, can be a significant challenge for manufacturers and one that they may feel is best left to an external specialist handling the work on a sub-contract basis.

This approach makes sense in many ways but can pose challenges in turnaround times and in ensuring overall control of the process, especially as the demand from customers for traceability in the form of detailed data and reporting continues to grow. However, handling plating in-house also poses its own challenges, especially when undertaken manually.

The Challenges of In-House Plating

Most traditional plating processes necessitate the use of immersion tanks, which can contain large quantities of hazardous chemicals. At some point, these tanks will need to be refilled and the old contents disposed of.

Individuals may be understandably reticent about taking on this type of work, while companies facing ever tighter local and international health and safety regulations will inevitably be seeking ways to minimize manual handling of, and exposure to, harmful chemicals – not only to protect employees, but to reduce outlay and management around protective equipment.

Manual plating has an inherent risk of inconsistencies between the treatments applied to individual components, whether it is the time that the component is exposed to the chemical, the current drawn during the plating process, operating temperature, and more. These inconstancies are only likely to be heightened when several platers are involved in plating the same components, whether they are working simultaneously or on different shifts. This again represents a significant issue when it comes to providing the level of detailed reporting and traceability clients are now demanding.

A further challenge surrounds throughput. Traditional tank plating can be a slow process, delayed as much by the delivery of parts to the individual workstations as by the plating process time itself. Companies are facing ever more stringent customer deadlines and inevitably need to consider options for speeding up the plating process.

The Case for Selective Brush Plating

A solution proven in tackling many of these issues is the implementation of selective brush plating.

In this process, a direct current from a rectifier is applied via an anode that is placed into direct contact with the component to be plated. The anode is covered in cotton, polyester, or other materials that hold solutions to enable it to act as a brush. Once the anode is thoroughly saturated in the solution, the deposit is applied to the negatively charged part. Brush plating requires movement between the anode and the part, which can be accomplished by moving the anode over the part, moving the part while keeping the anode stationary, or moving both.

This process increases precision as operators can focus only on the specific parts of a component that need to be plated. It also means time and materials are not wasted on plating or masking off areas that may not require the deposit. In addition, the selective plating process eliminates the need for large tanks, and working close to large volumes of chemicals.

The Benefits of Automation

It is clear that adopting selective brush plating as an alternative to traditional tank plating can have significant benefits. However, these benefits can become even more pronounced when the selective brush plating is partially or fully automated. While plating is an area which traditionally has been slower than others to automate, it is gathering pace in recent years because of the achievable benefits and reduced costs to implement.

The level of automation required will inevitably depend on available budgets and the size, type, importance, and value of the parts being treated. At the simplest level, the introduction of automated rectifier controls will help to ensure consistency of current and voltage applied to individual components.

The next stage of automation would see the introduction of semi or fully automated tool handling. Handling larger, heavier tools inevitably impact operator fatigue and is an area of work which many companies will wish to seek to minimize. Automating the tool handling contributes to consistency within the process from one part to the next.

Next, is the complete automation of the process, using robots to maneuver the parts to the process, or bring the process to the parts through tool handling, or both. This reduces the need for manual handling within the process altogether while making for a more even and consistent deposit meaning reduced failures down the line.

Human error is effectively eliminated, as the entire process is automatically controlled through a user-friendly human-machine interface (HMI). Meanwhile, given the fully automated nature of the system, detailed reports can be immediately accessed on all aspects of the process from batches down to individual castings. This provides complete control and traceability, and therefore peace of mind regarding consistency and quality to owners and, in turn, to customers.

The equipment available to fully automate the selective brush plating process is so flexible that almost any application can be catered to, to meet a customer’s exacting plating requirements.

Continued Innovation

Innovation continues at a great pace in the area of plating automation. The latest development comes in the form of a fully portable automated electroplating system, able to be moved directly to a specific component for in situ plating. The system features cutting-edge dripless functionality, with all chemicals going back into the machine with no need for drip trays, making for a cleaner, more environmentally friendly, and safer working area.

While suitable for use by a skilled operator, this system also allows for the introduction of a robot to handle the part and/or undertake the plating task, making the process fully automated. Contributing significantly to both throughput and productivity, this innovation further reduces manual handling and is ideal for tasks where rapid turnaround is needed with no time for a part to be disassembled, removed and taken away for treatment elsewhere.

For further information visit www.sifcoasc.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!