Concrete Coatings, Part III

Coating Resins

Example of efflorescence. Credit: Courtesy of Michael Praw

In the last couple of columns, we discussed concrete as a substrate and some of the properties needed by concrete coatings. In this column, I will discuss resins for concrete coatings. The first part will cover one-component (1K) coatings, and the second will cover two-component (2K) coatings. We will also discuss the different requirements for basecoats and topcoats.

Concrete limits certain coatings chemistries as basecoats due to its alkalinity and water content. Alkyd coatings are not a direct-to-concrete option because of the saponification potential of the resin, due to the high alkalinity of concrete. Isocyanate-containing coatings also have limitations due to the water-isocyanate side reaction, which creates carbon dioxide and foam in the coatings. These isocyanate-containing 2K coatings include polyurethane and polyurea (polyaspartics are a subset of polyurea coatings). However, isocyanate-containing coatings make excellent topcoats.

So, what chemistries work on direct-to-concrete coatings? The main resin type for 1K coatings is water-based acrylic and modified water-based acrylic, though some solution acrylics are still used. For 2K systems, epoxy systems predominate. Let’s explore them.

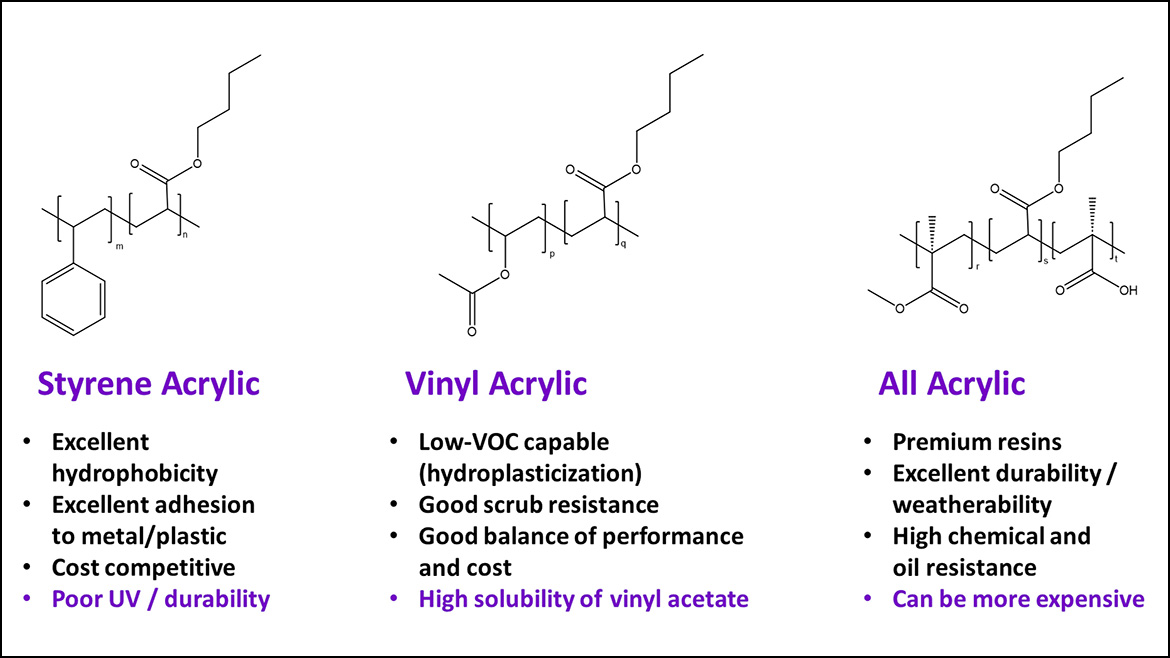

Water-based acrylics make up the majority of 1K coating systems for concrete, with all-acrylic resins having the best balance of properties, including exterior durability. Styrene acrylics also work very well (sometimes better) than pure acrylics, except for poorer ultraviolet/yellowing resistance caused by the styrene. Vinyl acrylics are limited to vertical surfaces on concrete due to hydroplasticization caused by water contact. This softening when wet greatly reduces the coating's physical properties. Figure 1 highlights the differences in acrylic chemistries. Smaller-particle-size acrylic emulsions can have better adhesion due to penetrating the pores in rough concrete, though this is less effective on polished concrete.

Many decorative acrylic coatings involve staining the concrete and then adding a clearcoat. Care should be taken with the stain to ensure it is not too close to critical PVC and has excess binder. Otherwise, the topcoat will adhere to the stain, but the stain will not adhere well to the substrate, often leading to cohesive or adhesive coating failure.

1K acrylic resins can be blended with other resins to change the properties, with polyurethane dispersions (PUD) used to help increase physical properties. When the correct polyurethane dispersion is added, abrasion resistance and other physical properties are improved. The usable temperature range is also extended, making the coatings more flexible at low temperatures and harder at elevated temperatures. The disadvantage is the increased cost of polyurethane dispersions compared to acrylics.

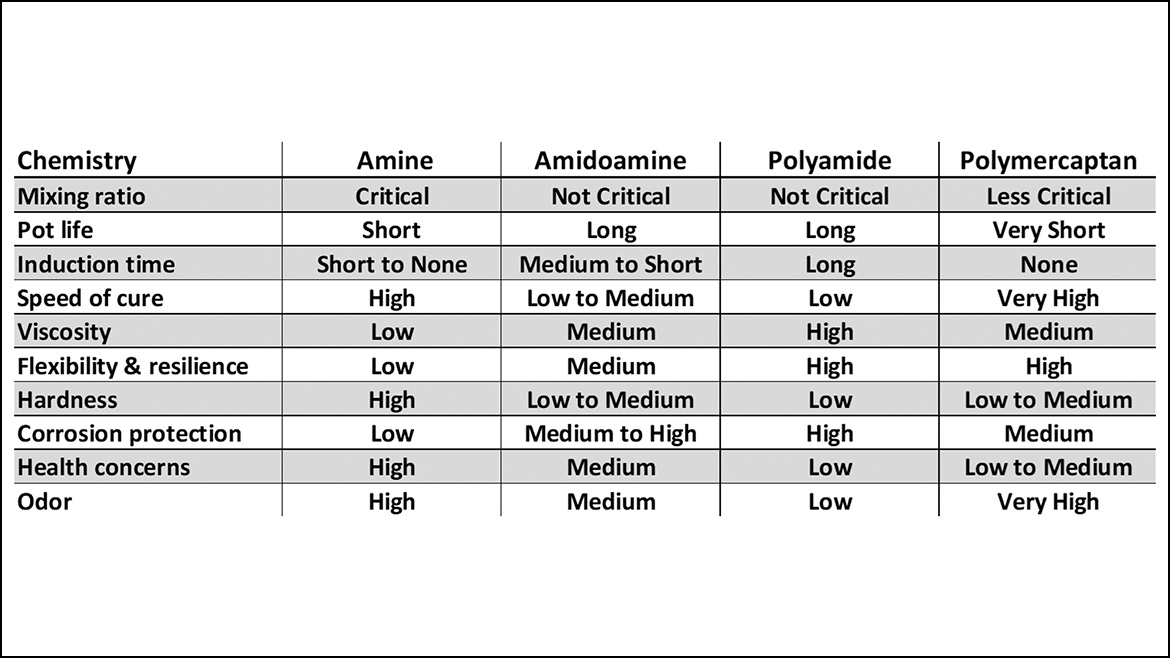

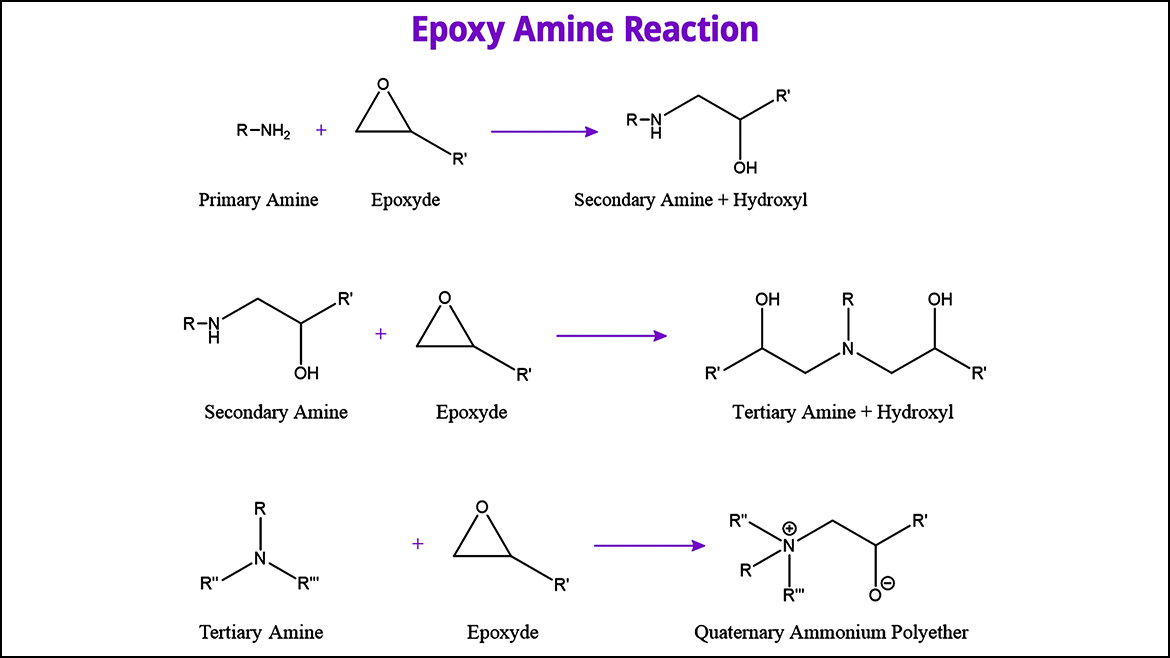

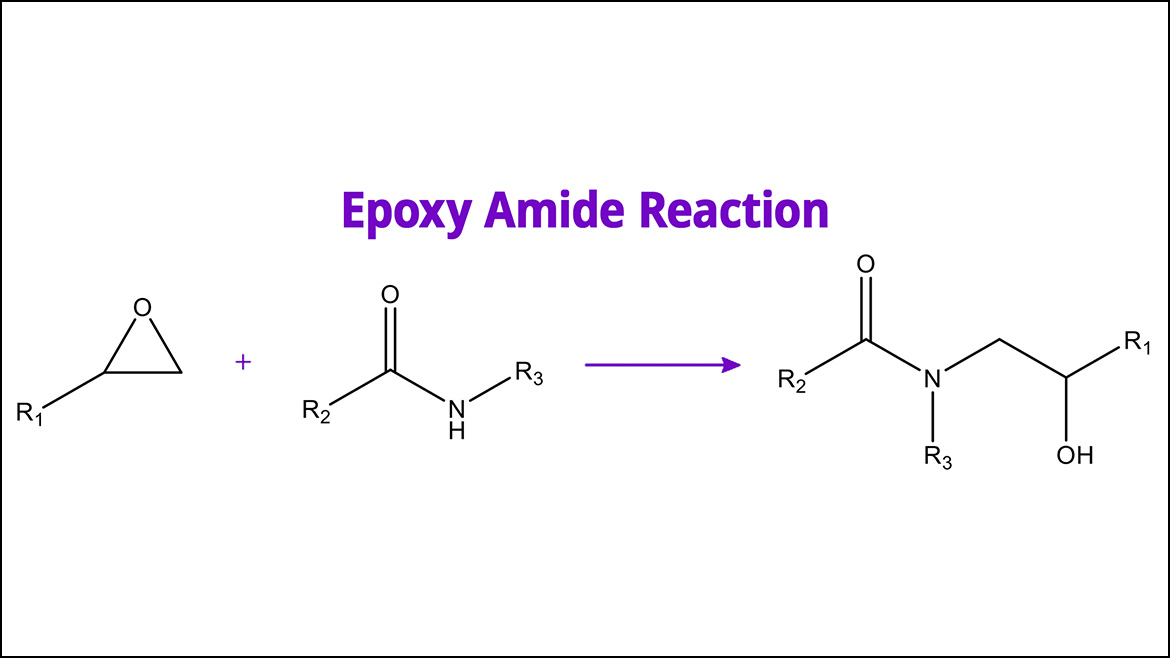

For 2K direct-to-concrete coatings, epoxy chemistry is by far the leader in performance. The major disadvantage of epoxies is their poor exterior durability and moderate abrasion resistance. Table 1 summarizes the differences in epoxy curing agents and their properties on the coating. Figure 2 shows the epoxy-amine reaction, and Figure 3 shows the epoxy-amide reaction. With epoxy resins, the type of curing agent used plays a large role in determining the final properties of the coatings, but environmental, health and safety (EHS) concerns will limit certain chemistries, such as amine, to professional contractors only due to risks to the applicator. Most epoxy coatings for the homeowner (do-it-yourself) are based on epoxy-amide chemistry.

To improve the abrasion resistance or exterior durability of epoxy-based concrete coatings, they need to be top coated. This is where isocyanate-based coatings are used for 2K applications and acrylic/acrylic-PUD systems for less-demanding applications. These isocyanate-based systems are generally divided into two categories, based on isocyanate chemistry: aliphatic and aromatic. Aliphatic isocyanate systems have excellent exterior durability and very good abrasion resistance but are high in cost. Aromatic isocyanate systems have poor exterior durability but excellent physical properties and can be 100% solids. One hundred percent solids urethane systems make excellent self-leveling coats for flooring applications.

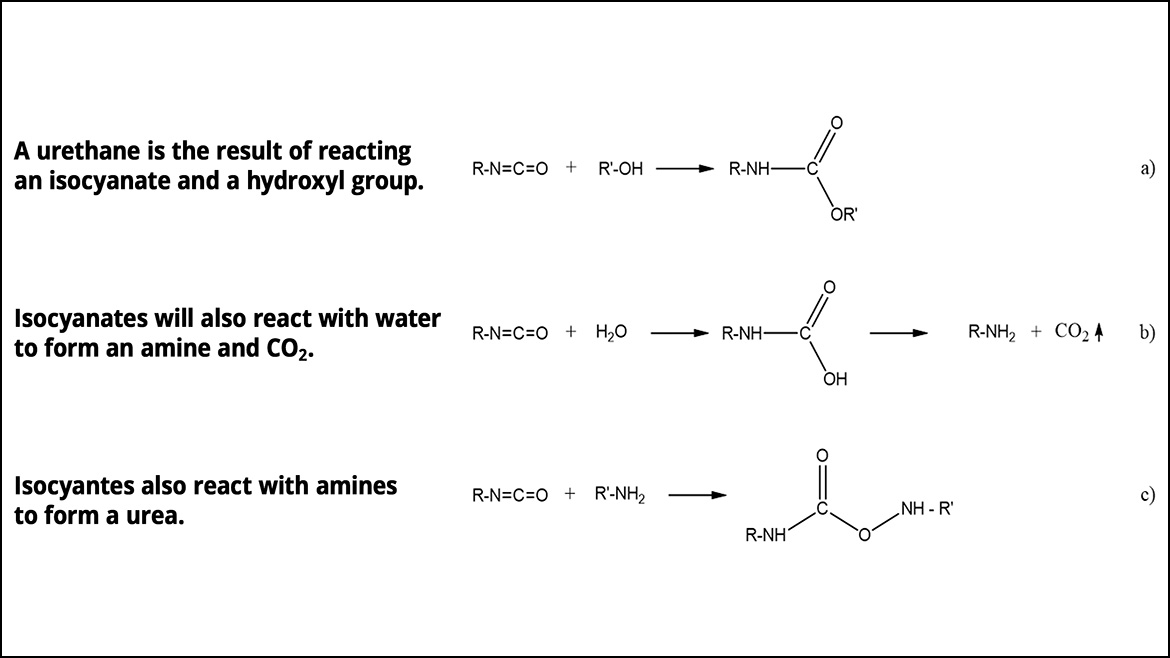

The main difference in the resin side of these coatings is the resin functionality. Figure 4 shows the urethane and urea reactions, as well as the water reaction. An isocyanate will react with a hydroxyl group to form a (poly)urethane (Figure 4a). It will react with an amine to form a (poly)urea (Figure 4c). Isocyanates will also react with water to form an amine and CO2, which will foam the coating (Figure 4b). The amine then reacts with another isocyanate to form a urea. Performance-wise, with all things being equal, polyurethane will have a better balance of hardness and flexibility compared to polyurea, but polyurea will have a significantly faster cure time. In aliphatic isocyanate-based systems, polyurethane will have better exterior durability.

Concrete coatings face many challenges, mostly due to the nature of the substrate, but with the proper selection of the resin system, superior performance is possible. 1K acrylic-based systems are easy to apply, work well on vertical concrete but have moderate, at best, properties for floor coatings. If superior-performance exterior coatings are required, an epoxy primer with an aliphatic urethane or urea topcoat is hard to beat. For interior coatings, including parking decks, an epoxy primer with an aromatic urethane self-leveling topcoat works best.

All information contained herein is provided "as is" without any warranties, express or implied, and under no circumstances shall the author or Indorama be liable for any damages of any nature whatsoever resulting from the use or reliance upon such information. Nothing contained in this publication should be construed as a license under any intellectual property right of any entity, or as a suggestion, recommendation, or authorization to take any action that would infringe any patent. The term "Indorama" is used herein for convenience only, and refers to Indorama Ventures Oxides LLC, its direct and indirect affiliates, and their employees, officers, and directors.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!