Sustainable Paper Packaging: A Natural-Based Barrier Solution

January 13, 2025

Sustainable Paper Packaging: A Natural-Based Barrier Solution

January 13, 2025LuisPortugal / iStock via Getty Images Plus

Paper-based packaging has emerged as a promising alternative to plastic; however, balancing sustainability with performance remains a significant challenge. A groundbreaking innovation — a 100% bio-based coating derived from tomato peels (cutin dispersion) — provides water, oil and grease resistance comparable to synthetic polymers while overcoming the limitations of other bio-based materials. This coating excels in heat sealability, acts as a barrier against MOSH/MOAH substances and addresses concerns related to harmful contaminants in recycled packaging. By utilizing tomato peels, the technology aligns with circular economy principles, reducing waste and environmental impact. This advancement marks a pivotal step toward sustainable food packaging that prioritizes both functionality and environmental responsibility.

Advancements in Barrier Coating Technologies in Food Packaging

Maintaining food quality by hindering oxygen and moisture diffusion and minimizing waste are hallmarks of effective food packaging. Several technologies impart barrier and thermo-sealing properties to paper. This article critically evaluates these coating methods, focusing on their environmental impact and recyclability.

Metallization

An atomic layer of aluminum or aluminum oxide is deposited onto a plastic liner (BOPET film) using vacuum deposition techniques. The metal layer is then transferred to paper via adhesive. It acts as an excellent barrier against oxygen and moisture. However, vacuum-deposited coatings are fragile and can easily crack, reducing performance. Despite excelling in oxygen and moisture resistance, their fragility necessitates protective layers, which can lead to non-recyclable BOPET leftovers.

Fossil-Based Coatings

Fossil-based coatings, such as acrylics, PVAs and EAA, use synthetic polymers in water to create barriers. Additives like waxes and nanoparticles enhance performance. While effective, these coatings may limit paper recycling and pose microplastic risks. Heat sealability can be achieved, but these solutions do not align with long-term sustainability goals and remain a potential source of microplastic pollution.

Bio-Based Coatings

Derived from renewable resources such as starch, cellulose, alginate, chitosan and proteins, bio-based coatings offer sustainable alternatives to fossil-based options. They reduce environmental impact and excel in oil and grease resistance but often lack water resistance and heat sealability. This limitation presents opportunities for innovation and product development.

Hybrid Coatings

Hybrid coatings combine fossil-based and bio-based materials, such as starch-based polymers and other sustainable additives, to achieve barrier properties. While effective against oil and grease, they often require fossil-based coatings in multilayer structures to meet water resistance demands.

Extrusion Coatings

This process applies a thin layer of plastic (typically polyolefins) onto a paper substrate to enhance moisture resistance and durability. However, the tight bond between paper and plastic compromises recyclability, leaving incineration as the only disposal option.

PFAS

PFAS are fluorinated chemicals used for decades due to their ability to repel water, oil and grease. Their harmful bioaccumulation in the food chain has led to bans, necessitating safe, sustainable alternatives.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

As the demand for eco-friendly barrier papers surges, exploring new coating technologies becomes imperative. The journey towards responsible packaging requires a nuanced approach that carefully balances performance with environmental concerns.

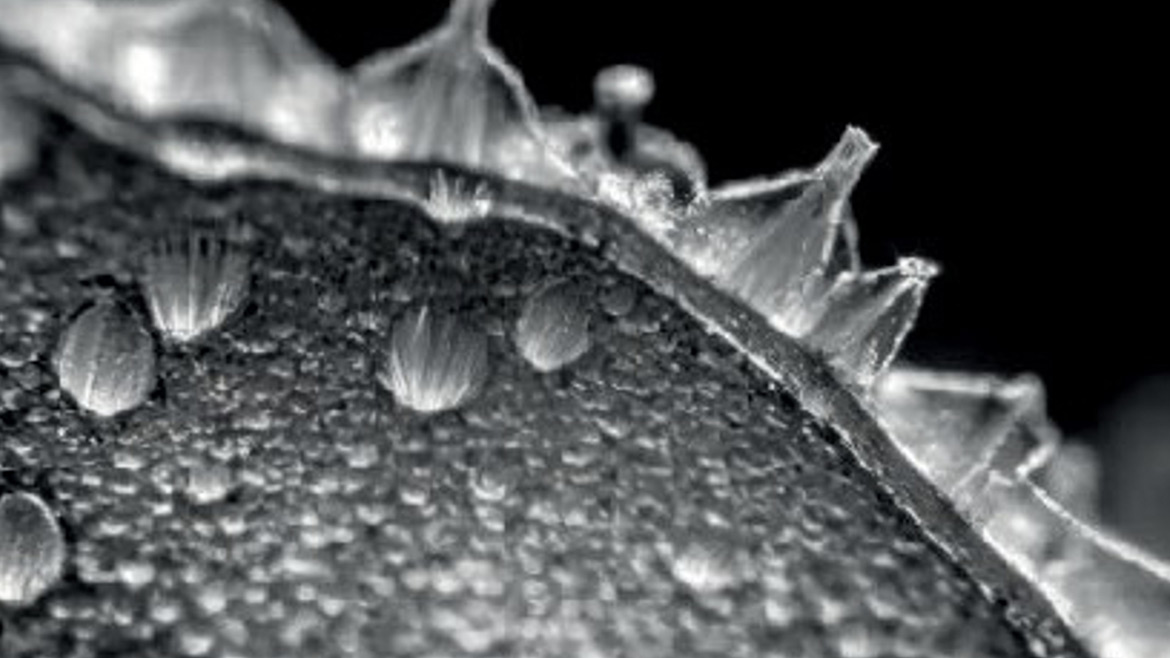

Biomimicry: Nature’s Blueprint for Sustainable Barrier Materials

Lamberti’s pursuit of advanced barrier materials takes inspiration from nature’s ingenious design principles. Over millennia, evolution has crafted optimal solutions, offering invaluable insights for developing sustainable innovations. This biomimetic approach draws from the remarkable barrier properties of plant cuticles, which can effectively contribute to a sustainable future in food packaging.

Plant cuticles, primarily composed of the biopolymer cutin, shield fruits, leaves and stems from environmental threats. Recognizing the potential of this intricate

Harnessing Tomato Peels: A Sustainable Feedstock

Tomatoes, with a global production of 187 million metric tons annually (FAOSTAT 2020), generate significant by-products such as tomato peels, estimated at 7 million metric tons per year. These peels represent a valuable resource for extracting cutin.

The R&D team developed an innovative, patented process to transform virgin cutin into a waterborne dispersion, which brings barrier properties to paper substrates. This breakthrough bridges the gap between natural materials and practical applications, addressing two key challenges:

- Water dispersibility: Enables application through standard coating techniques.

- Barrier properties: Provides resistance to water, oil and grease, as well as thermo-sealing properties.

Results at a Glance

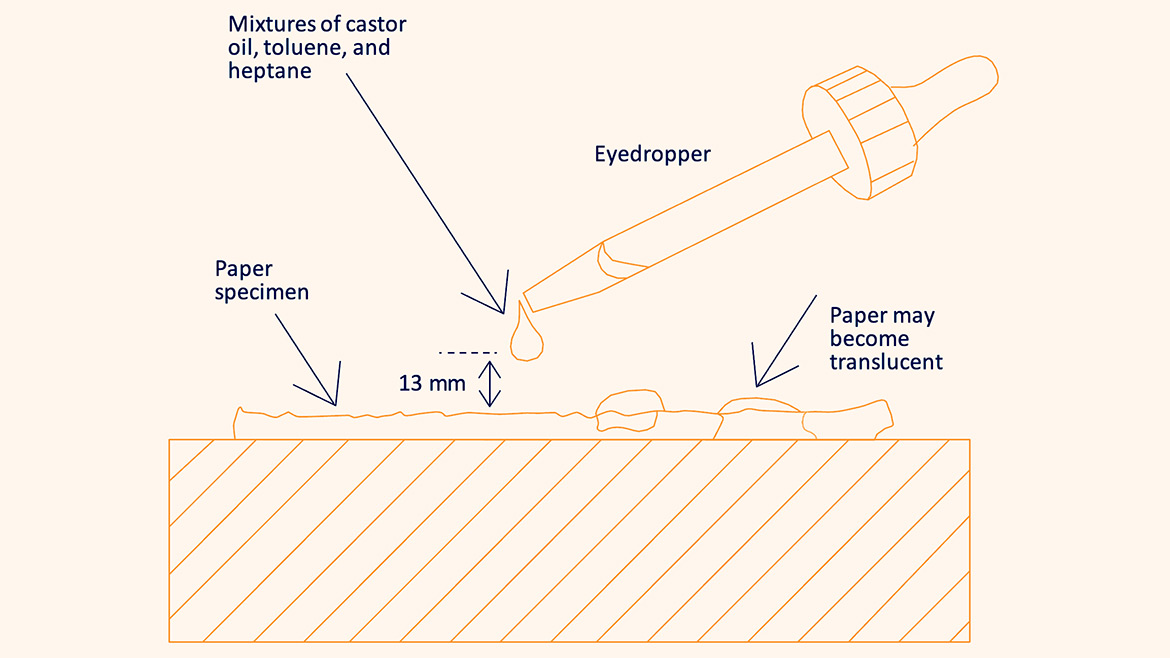

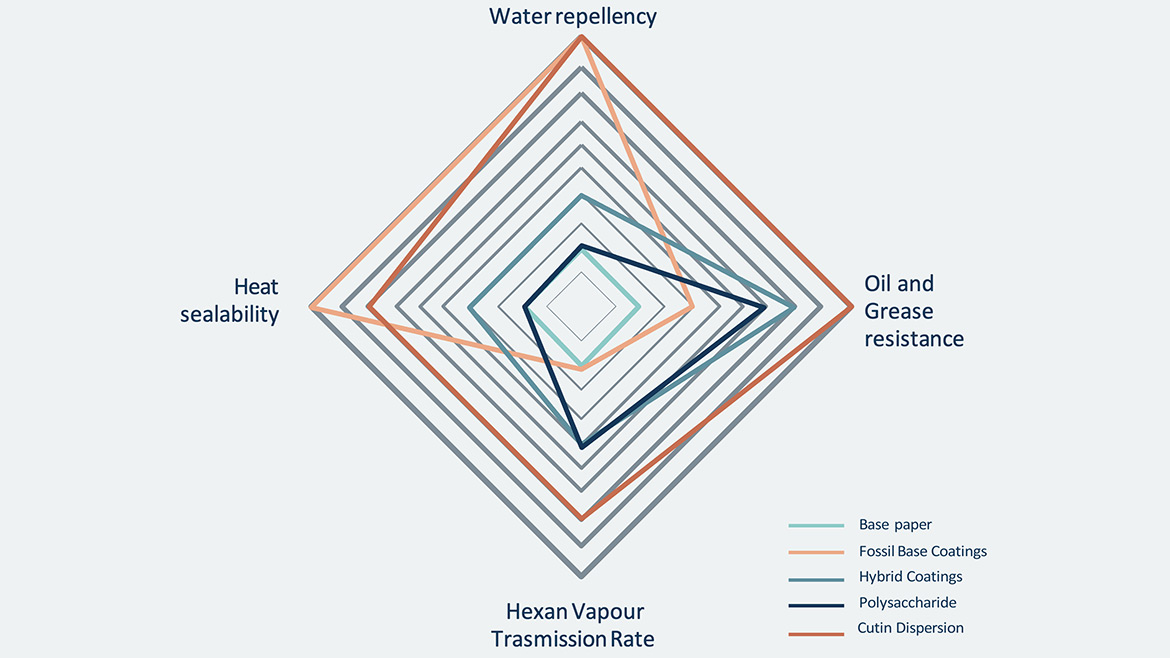

In our pursuit of biomimetic barrier solutions, we evaluated different coatings on standard 80 g/m² paper using wire-wound rod application with a dry add-on of 5–6 g/m², followed by drying at 85°C for 1 minute. The coated paper underwent rigorous testing according to standard methods to assess water, oil and grease resistance, hexane resistance and heat sealing (Table 1 and Figure 4).

TABLE 1 | Main barrier coating performance tests.

Testing Methodology and Standards

We employed established tests to comprehensively evaluate the performance of various coatings.

Coating Selection and Application

Several waterborne coatings were prepared:

- Polysaccharide: Potato starch-based dextrin

- Fossil-based coatings: Acrylic polymer

- Hybrid coatings: Acrylic-polysaccharide hybrid copolymer (50% bio-based content)

- Cutin dispersion coating: 100% bio-based content

These coatings were applied to kraft monoglazed paper (80 g/m²) at similar viscosities (approximately 5.5 g/m² dry) and dried at 60 °C for 1 minute.

Discussion: Breaking Through Sustainability Barriers

The data underscores the inherent challenge of balancing water, oil and grease resistance in bio-based materials. Polysaccharides and grafted copolymers, while offering bio-content, demonstrate limited water resistance. Fully synthetic materials often excel in water holdout but compromise on oil and grease protection (Table 2 and Figure 5).

TABLE 2 ǀ Summary of key findings.

Cutin-based coating emerges as a game-changer. It achieves water resistance comparable to synthetic polymers while delivering excellent oil and grease resistance on par with bio-based options.

Furthermore, cutin-based coating boasts remarkable heat-sealing properties, significantly exceeding most bio-based materials. This ensures compatibility with existing packaging lines and facilitates efficient converting.

The low HVTR of cutin dispersion translates to a robust barrier against MOSH/MOAH, potentially mitigating concerns about retained solvents in recycled paper and cardboard. This characteristic further underscores its potential for safe and sustainable food packaging.

While naturality remains a core value, trade-offs between authenticity and consumer preference must be considered. Options for customization, such as natural colors and aromas, could allow the innovation to appeal to a broader audience while retaining its sustainable foundation.

Conclusion: A Sustainable Future for Packaging

Plastic pollution casts a long shadow over our planet, demanding immediate action. Paper-based packaging emerges as a promising alternative, yet achieving both sustainability and robust performance remains a challenge.

This article has explored these challenges, ultimately introducing a groundbreaking solution derived from a natural, abundant resource — tomato peels, transformed into a 100% bio-based coating. This cutin-based technology bridges the gap between environmental responsibility and exceptional functionality. It delivers outstanding water, oil and grease resistance, exceeding the performance of many conventional options.

Breaking Barriers, Achieving Balance

- Water holdout: Achieves water resistance comparable to synthetic polymers, addressing a longstanding limitation.

- Oil and grease protection: Maintains excellent oil and grease resistance, ensuring product integrity.

- Heat sealability: Superior sealing capabilities facilitate efficient conversion within existing packaging lines.

- MOSH / MOAH barrier: Low HVTR signifies a robust defense against these potentially harmful substances, enhancing food safety.

- Customization potential: Options for natural color and aroma appeal to diverse consumer preferences.

- Sustainability at its core: Utilizes a readily available by-product of the food industry, aligning with circular economy principles and minimizing waste.

By harnessing biomimicry and leveraging sustainable resources like tomato peels, cutin-based dispersion technology represents a paradigm shift in barrier coatings. It bridges the gap between performance and sustainability, paving the way for a future where eco-friendly packaging delivers exceptional functionality without compromising environmental responsibility.

For more information, click here.