Risk Factor: Complementary Pigment Combinations

Several pigment combinations are suitable for the formulation of green color shades. For economic reasons, “complementary pigment combinations” are often used. These are green shades that are generated by mixing yellow and blue pigments. However, these mixtures may bear significant risk in terms of weather fastness, especially when the fastness properties and the pigment concentrations are not balanced, or when the formulation contains a large portion of titanium dioxide. In combination with the effect of sunlight and weathering, all of this can lead to undesirable and unacceptable color changes in the coating.

Clariant undertook extensive tests to determine which pigment mixtures are suitable for outdoor use. Based on these tests, it could be demonstrated that different pigment mixtures generate color variations in green coatings, and suitable alternatives were identified. The results presented in this article for the color “green” can be generally transferred to other color shades.

Clariant undertook extensive tests to determine which pigment mixtures are suitable for outdoor use. Based on these tests, it could be demonstrated that different pigment mixtures generate color variations in green coatings, and suitable alternatives were identified. The results presented in this article for the color “green” can be generally transferred to other color shades.

Several pigment combinations are suitable for the formulation of green color shades. For economic reasons, “complementary pigment combinations” are often used. These are green shades that are generated by mixing yellow and blue pigments. However, these mixtures may bear significant risk in terms of weather fastness, especially when the fastness properties and the pigment concentrations are not balanced, or when the formulation contains a large portion of titanium dioxide. In combination with the effect of sunlight and weathering, all of this can lead to undesirable and unacceptable color changes in the coating.

Clariant undertook extensive tests to determine which pigment mixtures are suitable for outdoor use. Based on these tests, it could be demonstrated that different pigment mixtures generate color variations in green coatings, and suitable alternatives were identified. The results presented in this article for the color “green” can be generally transferred to other color shades.

Clariant undertook extensive tests to determine which pigment mixtures are suitable for outdoor use. Based on these tests, it could be demonstrated that different pigment mixtures generate color variations in green coatings, and suitable alternatives were identified. The results presented in this article for the color “green” can be generally transferred to other color shades.

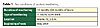

Test conditions of outdoor weathering.

Test Formulation, Process and Evaluation

The binder used in the tests was a non-drying alkyd resin based on synthetic fatty acids crosslinked with a highly reactive melamine resin. The selection of this binding agent allowed obtaining conclusive results already after 12 months of weathering exposure in Florida. The detailed testing conditions are listed in Table 1.

Composition of test pigmentations.

To obtain reproducible test results about the weather fastness of green coatings, the following inorganic pigments were used: phthalocyanine blue (C.I. Pigment Blue 15:2), chrome titanium yellow (C.I. Pigment Brown 24) and titanium dioxide (Rutile, C.I. Pigment White 6). This combination was identical in all of the tests but it was mixed with three different organic yellow pigments of varying chemical structure (Table 2):

• Monoazo/quinoxaziline-dion (C.I. Pigment Yellow 213);

• Quinophtalone (C.I. Pigment Yellow 138); and

• Monoazo/benzimidazolone (C.I. Pigment Yellow 194).

Due to the excellent weather fastness of the inorganic pigments, no color variations were to be expected in these colorants. Yet the situation is different for the organic yellow pigments, which are a critical component. If the used yellow and blue pigments vary in terms of weather fastness, the bleaching and chroma loss of the yellow pigment causes a clearly visible and measurable color shade variation towards blue.

The different coating formulations were applied onto metal sheets. Before the tests, half of each sheet had been cleaned with lukewarm soapy water, and the other half with a coating detergent. In the following coloristic tests of the coated specimens, the color shade was measured with a spectral photometer d/8°. After weathering, the change (dE in CIELAB units, classification into dC, dH, dL) was determined in comparison with the non-weathered standard. The gloss evaluation was done with a gloss meter (Haze/Gloss 20°). Again, the crucial parameter was the gloss change after weathering compared to the initial gloss.

• Monoazo/quinoxaziline-dion (C.I. Pigment Yellow 213);

• Quinophtalone (C.I. Pigment Yellow 138); and

• Monoazo/benzimidazolone (C.I. Pigment Yellow 194).

Due to the excellent weather fastness of the inorganic pigments, no color variations were to be expected in these colorants. Yet the situation is different for the organic yellow pigments, which are a critical component. If the used yellow and blue pigments vary in terms of weather fastness, the bleaching and chroma loss of the yellow pigment causes a clearly visible and measurable color shade variation towards blue.

The different coating formulations were applied onto metal sheets. Before the tests, half of each sheet had been cleaned with lukewarm soapy water, and the other half with a coating detergent. In the following coloristic tests of the coated specimens, the color shade was measured with a spectral photometer d/8°. After weathering, the change (dE in CIELAB units, classification into dC, dH, dL) was determined in comparison with the non-weathered standard. The gloss evaluation was done with a gloss meter (Haze/Gloss 20°). Again, the crucial parameter was the gloss change after weathering compared to the initial gloss.

Weathering results for green color shades.

Results

Table 3 shows the results of the weathering tests after 12 months. As expected, the variations in the specimens using C.I Pigment Yellow 213 (Version 1) are relatively small. The color shift towards blue is hardly accentuated and altogether acceptable.

However, the use of C.I. Pigment Yellow 138 (Version 2) shows a significant shift towards the blue and less chromatic spectrum. Based on previous experience, this change will become more accentuated in Florida weather after 24 months. There is also a clear loss of gloss in P.Y.138 after only 12 months of weathering.

The use of C.I. Pigment Yellow 194 (Version 3) shows the typical result of a pigment mix with extremely varying weather fastness properties. The color shift toward blue is almost 15 dE units, and it also shows a clear chroma loss. This type of specimen also demonstrates well the importance of the pigment concentration. In the near full-tone range, P.Y. 194 features “good” to “very good” weather fastness, but in low concentrations, it drops significantly.

These test results emphasize the impact of the color pigments on the weather fastness of the entire coating system. To produce coatings with a long lifespan and permanent color fastness, it is recommended, based on these findings, to abstain from using complementary pigment combinations. For green pigmentation, suitable organic green pigments are C.I. Pigment Green 7 or Pigment Green 36 (depending on the desired color shade), which may be given any desired color nuance. Also, these green pigments are weatherfast, so color changes caused by sun and weather can be easily avoided.

This paper is based on an article presented in the “European Coatings Journal”, Vincentz Verlag, Nuremberg, May 2007.

However, the use of C.I. Pigment Yellow 138 (Version 2) shows a significant shift towards the blue and less chromatic spectrum. Based on previous experience, this change will become more accentuated in Florida weather after 24 months. There is also a clear loss of gloss in P.Y.138 after only 12 months of weathering.

The use of C.I. Pigment Yellow 194 (Version 3) shows the typical result of a pigment mix with extremely varying weather fastness properties. The color shift toward blue is almost 15 dE units, and it also shows a clear chroma loss. This type of specimen also demonstrates well the importance of the pigment concentration. In the near full-tone range, P.Y. 194 features “good” to “very good” weather fastness, but in low concentrations, it drops significantly.

These test results emphasize the impact of the color pigments on the weather fastness of the entire coating system. To produce coatings with a long lifespan and permanent color fastness, it is recommended, based on these findings, to abstain from using complementary pigment combinations. For green pigmentation, suitable organic green pigments are C.I. Pigment Green 7 or Pigment Green 36 (depending on the desired color shade), which may be given any desired color nuance. Also, these green pigments are weatherfast, so color changes caused by sun and weather can be easily avoided.

This paper is based on an article presented in the “European Coatings Journal”, Vincentz Verlag, Nuremberg, May 2007.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!