Light Stabilization Toolbox

Following a short summary of the various UV absorber chemistries developed over the years, both the absorption and the transmission characteristics of the various classes (including combinations thereof) are discussed below. Depending on the application and, in particular the sensitivity of the substrate used, suitable spectral coverage, as well as sufficiently high extinction at certain wavelengths (among other aspects), need to be recognized as important criteria in the selection of stabilizers.

Credit: BASF SE Credit: BASF SE

|

| Figure 1 Click to enlarge |

Conventional UV Absorbers for Coatings

The stabilization of coatings has for many years been a challenge for the paint industry. More than three decades ago it became evident that HALS (Hindered Amine Light Stabilizers) play a key role in the stabilization of polymers. Typically, these products are derivatives of 2’,2’,6’,6-tetra-methylpiperidine and act – once activated by UV-light and oxygen with formation of the nitroxyl radical – as radical scavengers, thereby preventing UV-light-induced degradation (cracking) of the polymer (coating). The mode of action of HALS products is largely independent of the film build applied; however, they do not absorb light at wavelengths above 250 nm. Therefore, in many applications, combined use with UV absorbers is essential to filter out the harmful components of UV light.

UV absorbers predominantly protect the underlying substrate, which can be a colored basecoat or plastic or wood. In contrast to HALS, the efficacy of UV absorbers depends (according to the Lambert-Beer law) on the molecule-specific extinction coefficient e, the concentration used and the film thickness applied. Additional crucial properties include low volatility, high photo stability, good compatibility and – depending on the spectral sensitivity of the particular substrate – adequate spectral coverage.

Credit: BASF SE Credit: BASF SE |

| Figure 2 Click to enlarge |

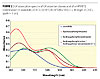

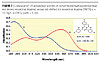

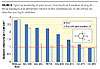

Between the early 1970s and the 1990s a variety of UV absorber classes and chemistries were developed and introduced to the market. The general structures of these chemistries are shown in Figure 1. In the late 1970s, oxanilide UV absorbers were already almost entirely replaced by various hydroxyphenyl benzotriazoles (BTZ), which became the dominant UV absorber class during the 1980s and continue to be so for a variety of traditional applications. These materials were already characterized by much broader spectral coverage and much better photo stability. In spite of the dominant position of the hydroxyphenyl benzotriazoles, there are still requirements that cannot be satisfactorily met with these products due to certain technical limitations of their chemistry. These include limited absorption at shorter wavelengths, interaction issues with certain metal (e.g., Al-based) catalysts, leading to significant yellowing, as well as inadequate protection of the substrate at reduced film build. Development efforts in the 1990s resulted in the introduction of the first generation of hydroxyphenyl triazine (HPT) UV absorbers (general structure in Figure 1)

Credit: BASF SE Credit: BASF SE |

| Figure 3 Click to enlarge |

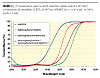

Generally speaking, hydroxyphenyl triazines exhibit much less tendency to interact with certain metal catalysts and even better photo stability than hydroxyphenyl benzotriazoles, as well as high absorption at shorter wavelengths. These features make this UV absorber class highly versatile in terms of both traditional and advanced applications such as UV curing. Furthermore, combinations with BTZ allow broader spectral coverage than HPT alone, along with superior protection at short wavelengths versus BTZ alone.

The comparative UV absorption spectra of the above classes as well as of a BTZ/HPT combination (example 1:1 ratio) are shown in Figure 2 and the corresponding UV transmission spectra in Figure 3.

Driving Forces for UV Absorber Innovation

Hydroxyphenyl benzotriazoles and hydroxyphenyl triazines developed during the 1980s and 1990s meet the requirements of the majority of traditional applications. Challenges beyond these applications include optimization of film builds (i.e., thin film applications) and increasing use of water-based coatings requiring compatible UV absorbers without compromising on performance as well as of materials light sensitive at wavelengths not covered by conventional UV absorbers.

Advanced Hydroxylphenyl Triazine UV Absorbers for Thin Film Applications

Credit: BASF SE Credit: BASF SE |

| Figure 4 Click to enlarge |

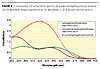

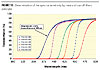

As shown in Figure 2, conventional BTZ and HPT UV absorbers exhibit fairly similar extinction, except in the 300 nm range. Adequate UV protection at low film builds can therefore only be achieved through significantly higher dose levels, which in turn may compromise the secondary properties of the paint film.

The more recent development of advanced chromophores based on hydroxyphenyl triazine chemistry has allowed up to 3.5 times higher extinction than the state of the art. This extremely high extinction (Figure 4) allows the application of thin films along with superior UV protection at comparatively low dose levels. The position of the absorption maximum in the 320-330 nm range also makes these chromophores interesting candidates for the protection of substrates sensitive at this wavelength range, e.g., polycarbonate.

Credit: BASF SE Credit: BASF SE |

| Figure 5 Click to enlarge |

As mentioned earlier, the efficacy of a UV absorber depends both on its absorption characteristics and on its secondary properties, such as photo stability, which needs to be very high. This is particularly important in thin film applications, where the product’s inherent stability rather than the internal filter effect (i.e., UV absorber molecules protecting each other) plays the dominant role.

Figure 5 shows the UV remission (i.e. reflectance) spectra of 2K clearcoats applied over silver metallic basecoat at film builds of 20 µm and 40 µm respectively. The spectra were recorded before and after 54 months Florida exposure. Despite the higher film build applied, essentially zero absorption is recorded for the hydroxyphenyl benzotriazole after long-term exposure. The spectra for the advanced hydroxyphenyl triazine (HPT), however, are essentially identical, which in turn can be interpreted as a result of its superior photo stability.

Credit: BASF SE Credit: BASF SE |

| Figure 6 Click to enlarge |

The results of 54-month Florida tests with 2K clearcoats (40 µm standard film build versus reduced film build; 20 µm) over both violet and silver metallic basecoats are summarized in Figure 6. The results clearly show that only the advanced hydroxyphenyl triazine technology allows superior protection at low film builds, whereas delamination is observed in the presence of conventional UV absorbers.

Red-Shifted UV Absorbers

The spectral coverage as such, as well as the position of the absorption maximum, are determining factors in UV stabilization of substrates sensitive at wavelengths that are not, or not sufficiently, covered either by conventional or advanced chromophores. These wavelengths extend from the ≥ 360 nm range to the visible and slightly above.

Credit: BASF SE Credit: BASF SE |

| Figure 7 Click to enlarge |

A shift in the absorption spectrum of the UV absorber can be achieved to a significant extent through specific substitution patterns; however, there are obviously limitations both in terms of chemistry and color. The more the spectrum is shifted towards the visible, the higher the risk of bringing in too much color. This in turn means that a proper balance needs to be achieved between the spectral coverage and the product’s inherent color.

Red-Shifted UV Absorbers for Wood Protection

As described in previous publications(1,2), both UV and visible light lead to decomposition of the lignin structure of wood, resulting in discoloration/darkening of pale woods in particular. In order to filter out the UV light component as far as possible, broader spectral coverage is needed than can be achieved with conventional UV absorbers. Figure 7 shows the comparative UV absorption spectra of a conventional hydroxyphenyl triazine (mono-resorcinol triazine) versus a red-shifted tris-resorcinol triazine (TRITA). Modification of the substitution pattern at the triazine moiety in this case allows a significant shift of the absorption maximum from 290 nm to 360 nm.

Credit: BASF SE Credit: BASF SE |

| Figure 8 Click to enlarge |

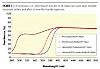

As indicated above, the decomposition of the lignin structure leads to formation of colored chromophores. Figure 8 shows the relative intensity of the carbonyl signal at 1730 cm-1 determined by FTIR analysis of pine samples. The relative intensity is the intensity measured after Xenon-WOM exposure relative to the intensity prior to exposure and correlates with the formation of new chromophores, i.e., the higher the value, the more extensive the decomposition of the lignin.

Cutting out the UV light either by cut-off filters (which allow a certain wavelength range to be selectively cut out, i.e., a filter labeled GG 320 excludes all wavelengths below 320 nm, a filter labeled GG 385 excludes all wavelengths below 385 nm, etc.) or by the red-shifted tris-resorcinol triazine (TRITA) UV absorber in lieu of a filter can greatly reduce the formation of colored chromophores (Figure 8). Since such species, however, are also being formed in the visible range, sufficient protection can scarcely be achieved by the UV absorber alone. In order to fully prevent their formation, spectral coverage as far out as > 450 nm would be needed (Figure 8), which in turn would result in a major color impact by the UV absorber.

Credit: BASF SE Credit: BASF SE |

| Figure 9 Click to enlarge |

Therefore, a modified concept involving specific co-stabilization was developed. Such co-stabilizers, which are chemically based on free nitroxyl radical chemistry (Figure 8), are typically used for pretreatment purposes. Such materials can trap the radicals formed on the wood surface by the visible light, thereby preventing photooxidation of lignin.

Figure 9 shows how the above concept is applied to clear-coated pine wood. After 1000 h Xenon-WOM exposure, the non-stabilized sample exhibits severe darkening. UV stabilization of the clear coat with TRITA can already greatly reduce the discoloration observed. If combined with lignin stabilizer, discoloration is further minimized.

Highly Red-Shifted UV Absorbers for Protection of CFRM and Epoxy Matrix

Novel substrates such as carbon-fiber-reinforced materials (CFRMs) are increasingly being used in a variety of applications, including automotive parts and hang-on parts for motor bikes, sports items such as bikes, the aerospace industry and rotor blades for wind turbines. CFRMs are characterized by low weight and superior mechanical properties. In order to achieve these properties, the carbon fiber is typically embedded in an aromatic epoxy matrix.

Credit: BASF SE Credit: BASF SE |

| Figure 10 Click to enlarge |

Systems or composites based on aromatic polymers (e.g., CFRMs) are inherently light sensitive, unless covered by pigmented coatings. The application of exposed carbon fiber, for example as a design element (CFRM coated with clearcoat only), is therefore highly challenging from a UV protection point of view. Fundamental studies conducted by means of cut-off filters (Figure 10), which allow certain wavelength ranges to be selectively cut out, show that the critical wavelengths include both the UV (i.e., 280 – 380 nm) and the 400 nm range.

Figure 11 shows the results of the determination of the spectral sensitivity of CFRMs by means of cut-off filters. In the experiments, the substrates were coated with 2K PU clearcoats stabilized with HALS only. The specimens were subsequently exposed for 4000 h in the Xenon-WOM, followed by humidity and adhesion tests.

The results clearly indicate that spectral coverage as far out as ~400 nm is mandatory in order to prevent degradation of the underlying epoxy matrix.

Credit: BASF SE Credit: BASF SE |

| Figure 11 Click to enlarge |

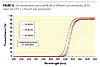

UV protection of such substrates requires UV absorbers (RUVA) with pronounced absorption into the visible (along with minimal color impact), sufficiently high extinction in the 400 nm range and superior photo stability. Figure 12 shows the UV transmission spectra recorded at different dose levels and a film build typical for coated CFRM. The results indicate that the critical wavelengths can be fully covered at dose levels between 1 and 2% based on the solids content of the clearcoat.

This has been confirmed in independent and comparative experiments conducted with RUVA-containing clearcoats versus conventionally stabilized clearcoats (Figure 13). The application of conventional UV absorbers results in early failure (delamination) after only 2000 h Xenon-WOM exposure due to the insufficient spectral coverage provided. In the presence of RUVA, however, superior protection is achieved. No signs of delamination or discoloration are observed even after 5000 h Xenon-WOM exposure. This in turn opens the door for new applications, e.g., the use of CFRMs as a design element.

Credit: BASF SE Credit: BASF SE |

| Figure 12 Click to enlarge |

Conclusion

The range of UV absorbers available today includes both conventional and advanced UV absorber technology. In traditional applications conventional hydroxyphenyl benzotriazoles as well as hydroxylphenyl triazines will certainly continue to play an important role. These products, however, do not meet the requirements for thin film applications or for applications requiring enhanced or specific protection at certain wavelengths. Development work has led to an extension of the available product range beyond conventional technologies, thereby allowing applications previously considered difficult or even impossible. Advanced hydroxyphenyl triazines are closing the gap for thin film applications or applications where enhanced protection at shorter wavelengths is necessary. Superior protection of wood substrates can be achieved by a specific concept, i.e., the combined use of red-shifted triazine-based UV absorbers and lignin stabilizers. Protection of systems or composites based on aromatic epoxies can be considered the biggest challenge in terms of the UV absorber properties needed. Today this can be realized through novel red-shifted UV absorber technology, which combines comparatively low color with broad spectral coverage reaching into the near visible.

Credit: BASF SE Credit: BASF SE |

| Figure 13 Click to enlarge |

Furthermore, the application of the various products as such or combinations thereof allow paint companies to adjust the protection to the level needed. In water-based coatings – although not further discussed in this paper – this is achieved through specific water- compatible product forms.

This article is based on the presentation “Light Stabilization Toolbox – tunable protection from UV to near visible,” given at the European Coatings Congress, 2009, in Nuremberg, Germany, by Adalbert Braig, BASF SE.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!