A Virtual Approach to Applicator Training

Proper hands-on training can produce immediate and long-term results in areas such as material conservation, waste and air emission reduction, reduced rework, and better finish quality. However, a significant drawback of traditional hands-on training has been the time and materials required to perform this task properly. A virtual reality training tool can provide paint and powder applicators with the benefits of hands-on training while eliminating the time and material requirements.

As chemists have developed new and advanced high-performance coatings, the materials used in the finishing industry have continued to evolve. Equipment manufacturers are integrating technologies into spray systems that were not even imaginable ten years ago. Hundreds of spray guns on the market claim to be the best by reducing overspray, providing energy savings and producing a high-quality finish. The one common denominator of these variables is the applicator using the spray equipment to apply the coatings. These individuals are the single most important aspect of the finishing process.

As of 2006, 82% of paint shops still applied paint (liquid and/or powder) manually, and most of these shops offered little or no formal hands-on training for the application of their coatings. This lack of training can be detrimental to the quality of work being produced by the shop, and it can also magnify the negative environmental impact of the overall finishing process. Conversely, proper hands-on training can produce immediate and long-term results in areas such as material conservation, waste and air emission reduction, reduced rework, and better finish quality.

A secondary concern of the coating application process is overall efficiency. Transfer efficiency, which is defined as the percentage of sprayed coating that is actually deposited onto the part, is the most common measurement of overall efficiency. Many variables affect transfer efficiency, including the application equipment; the surface area of the part being painted; and, the most critical factor, the skill of the applicator spraying the coating. The applicator has control over the setup of the application equipment, the triggering of the spray gun and the distance and angle of the spray gun in relation to the part. Because painting is already such a wasteful process, the true value of this skill is often ignored. The bottom line is that applicators have a lot of impact on the efficiency of a painting operation.

The cost of inefficiency can be overwhelming. Even with the most efficient equipment at his/her disposal, it is not uncommon for a coating applicator to spray with a transfer efficiency of 40% or less. This means that as much as 33 gallons of every drum of coating is wasted through overspray. With the cost of coatings and environmental noncompliance on the rise, one area that shop owners still have control over is the training offered to the coating applicators.

This three- to four-day training course emphasizes the use of a blended learning approach to enhance the learning experience of each trainee. A four-hour classroom session reviewing the basics of spray application is followed by intense hands-on practice and training on the techniques learned in the classroom. The hands-on portion is the most critical factor because it allows each trainee to gain experience actually applying coatings properly.

The biggest drawback of traditional hands-on training has been the time and materials required to perform this task properly. Dedicating a spray booth for training interrupts production, and a hands-on approach also requires the proper paint, spray equipment, personal protective equipment and extra parts on which to practice spraying. Substantial preparation and cleanup also are associated with this training method.

To combat these problems, the IWRC developed the VirtualPaint™ simulator using non-federal funds. The VirtualPaint is a virtual reality simulator that replicates the process of applying coatings to a surface. The simulator was developed by creating mathematical computer models of actual spray application data collected during the coating process. This data allows the simulator to give the user the look and feel of spraying without actually doing so (see Figure 1).

To combat these problems, the IWRC developed the VirtualPaint™ simulator using non-federal funds. The VirtualPaint is a virtual reality simulator that replicates the process of applying coatings to a surface. The simulator was developed by creating mathematical computer models of actual spray application data collected during the coating process. This data allows the simulator to give the user the look and feel of spraying without actually doing so (see Figure 1).

The highly capable and flexible system operates with computer simulation and virtual reality technologies. Spray applicators are able to use real spray application equipment while simulating the actual application process onto a virtual surface. By using virtual reality, many drawbacks of traditional hands-on spray application training are eliminated. A paint booth, safety equipment, solvents and a regulatory permit are no longer necessary. Additionally, the amount of time required to prepare the surface, mix the coatings and clean up is no longer a factor to consider in the training process.

This system allows for realistic hands-on painter training to be conducted in a more versatile and beneficial manner. The training can be conducted in a classroom with an unlimited amount of students. The instructor can provide demonstrations encompassing spray gun setup and application technique. After the demonstration, the instructor can critique the trainee’s techniques and identify their strengths and weaknesses.

Spraying with the simulator is similar to an actual spray application but with additional benefits. The instrumented spray gun allows applicators to control air pressure, flow rate and fan size in the same manner as on any other spray gun. Those factors can also be displayed on the screen for applicators to be able to completely understand how the spray gun operates.

Along with the benefits of learning spray gun operation, coating applicators are also provided with instantaneous feedback regarding their overall application skill. Film build average (mils), ounces of paint sprayed, elapsed time spent spraying, transfer efficiency and overspray are also immediately displayed. All of these factors combine to allow applicators a simulated judgment of the overall effectiveness of the training.

While all of the factors explained thus far are important, possibly the most useful display factor of the virtual reality simulator is its use of a single-color and multi-color assessment mode. The single-color paint mode is an approximation of the actual appearance of paint. In this mode, shades of a single color are used to indicate paint thickness. In the multi-color assessment mode (see the opening image), multiple shades of varying colors are used to indicate the thickness of the paint. In this mode, the surface color represents an area with no paint. Shades of blue represent values below the minimum recommended film thickness, shades of green represent values within target film thickness range, and shades of red represent thickness values that exceed the maximum recommended target. With these tools, trainees can easily see how their application techniques affect the overall quality of the coating.

By eliminating the need for a paint booth, compressed air, safety equipment, preparation work, along with operational hazards, volatile organic compound (VOC) emissions, hazardous waste and cleanup work, the virtual reality paint simulator is changing the dynamics of applicator training and bringing high-quality, consistent coatings within the reach of every finishing operation.

IWRC is a service, research, and training organization at the University of Northern Iowa. For more information about the IWRC, visit www.iwrc.org. More information about the VirtualPaint system can be found at www.virtualpaint.us.

The multi-color assessment mode allows trainees to see a contour image of the exact thickness of the coating while they spray. Photo courtesy of Lynn Treloar, NuVue Images.

As chemists have developed new and advanced high-performance coatings, the materials used in the finishing industry have continued to evolve. Equipment manufacturers are integrating technologies into spray systems that were not even imaginable ten years ago. Hundreds of spray guns on the market claim to be the best by reducing overspray, providing energy savings and producing a high-quality finish. The one common denominator of these variables is the applicator using the spray equipment to apply the coatings. These individuals are the single most important aspect of the finishing process.

As of 2006, 82% of paint shops still applied paint (liquid and/or powder) manually, and most of these shops offered little or no formal hands-on training for the application of their coatings. This lack of training can be detrimental to the quality of work being produced by the shop, and it can also magnify the negative environmental impact of the overall finishing process. Conversely, proper hands-on training can produce immediate and long-term results in areas such as material conservation, waste and air emission reduction, reduced rework, and better finish quality.

A Fundamental Problem

The fundamental skills of application may seem simple, but the majority of coating applicators struggle to apply finishes consistently within the target film thickness ranges specified by the coating manufacturer. Such inconsistencies can result in coating failures, rework and, ultimately, wasted time and money. Using a spray gun that claims to reduce overspray, provide energy savings and produce a high quality finish will accomplish little without the proper training.A secondary concern of the coating application process is overall efficiency. Transfer efficiency, which is defined as the percentage of sprayed coating that is actually deposited onto the part, is the most common measurement of overall efficiency. Many variables affect transfer efficiency, including the application equipment; the surface area of the part being painted; and, the most critical factor, the skill of the applicator spraying the coating. The applicator has control over the setup of the application equipment, the triggering of the spray gun and the distance and angle of the spray gun in relation to the part. Because painting is already such a wasteful process, the true value of this skill is often ignored. The bottom line is that applicators have a lot of impact on the efficiency of a painting operation.

The cost of inefficiency can be overwhelming. Even with the most efficient equipment at his/her disposal, it is not uncommon for a coating applicator to spray with a transfer efficiency of 40% or less. This means that as much as 33 gallons of every drum of coating is wasted through overspray. With the cost of coatings and environmental noncompliance on the rise, one area that shop owners still have control over is the training offered to the coating applicators.

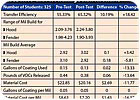

Table 1.

A Virtual "Hands-On" Approach

Basic applicator training can immediately improve the efficiency of the coating operation. STAR4D®, a federal program at the Iowa Waste Reduction Center (IWRC) in Cedar Falls, IA, has trained more than 300 military spray applicators over the last three years. Statistical data from this training has shown an immediate 18.42% average increase in applicator transfer efficiency and a 13.33% average reduction in material consumption (see Table 1).This three- to four-day training course emphasizes the use of a blended learning approach to enhance the learning experience of each trainee. A four-hour classroom session reviewing the basics of spray application is followed by intense hands-on practice and training on the techniques learned in the classroom. The hands-on portion is the most critical factor because it allows each trainee to gain experience actually applying coatings properly.

The biggest drawback of traditional hands-on training has been the time and materials required to perform this task properly. Dedicating a spray booth for training interrupts production, and a hands-on approach also requires the proper paint, spray equipment, personal protective equipment and extra parts on which to practice spraying. Substantial preparation and cleanup also are associated with this training method.

Figure 1. The VirtualPaint system allows trainees to see immediate results of their performance while they train. Photo courtesy of Lynn Treloar, NuVue Images.

The highly capable and flexible system operates with computer simulation and virtual reality technologies. Spray applicators are able to use real spray application equipment while simulating the actual application process onto a virtual surface. By using virtual reality, many drawbacks of traditional hands-on spray application training are eliminated. A paint booth, safety equipment, solvents and a regulatory permit are no longer necessary. Additionally, the amount of time required to prepare the surface, mix the coatings and clean up is no longer a factor to consider in the training process.

With VirtualPaint, trainees can see whether their technique is correct. The panel on the left shows inconsistent paint thickness and too much overspray, while the panel on the right shows consistent paint thickness and minimal overspray.

An Interactive Learning Tool

The simulator uses a real spray gun that is uniquely instrumented to allow the applicator full control over the fluid flow adjustment, fan pattern adjustment and the air pressure and trigger variability. When the spray gun trigger is pulled, a tracking device, which is attached to the spray gun, sends a signal to the tracker, which continuously tracks the position and orientation of the spray gun relative to the virtual surface.This system allows for realistic hands-on painter training to be conducted in a more versatile and beneficial manner. The training can be conducted in a classroom with an unlimited amount of students. The instructor can provide demonstrations encompassing spray gun setup and application technique. After the demonstration, the instructor can critique the trainee’s techniques and identify their strengths and weaknesses.

Spraying with the simulator is similar to an actual spray application but with additional benefits. The instrumented spray gun allows applicators to control air pressure, flow rate and fan size in the same manner as on any other spray gun. Those factors can also be displayed on the screen for applicators to be able to completely understand how the spray gun operates.

Along with the benefits of learning spray gun operation, coating applicators are also provided with instantaneous feedback regarding their overall application skill. Film build average (mils), ounces of paint sprayed, elapsed time spent spraying, transfer efficiency and overspray are also immediately displayed. All of these factors combine to allow applicators a simulated judgment of the overall effectiveness of the training.

While all of the factors explained thus far are important, possibly the most useful display factor of the virtual reality simulator is its use of a single-color and multi-color assessment mode. The single-color paint mode is an approximation of the actual appearance of paint. In this mode, shades of a single color are used to indicate paint thickness. In the multi-color assessment mode (see the opening image), multiple shades of varying colors are used to indicate the thickness of the paint. In this mode, the surface color represents an area with no paint. Shades of blue represent values below the minimum recommended film thickness, shades of green represent values within target film thickness range, and shades of red represent thickness values that exceed the maximum recommended target. With these tools, trainees can easily see how their application techniques affect the overall quality of the coating.

A New Training Option

Proper training allows applicators to be able to explore coating application and accumulation in an entirely new way, while improving the motor skills necessary for applying high-performance coatings appropriately. The virtual reality simulator presents applicators with an unlimited amount of practice parts and paint, while completely eliminating the production of hazardous waste or air emissions. Applicators are not restricted to training when the production line is down and therefore can continuously improve their skills whenever the simulator is running.By eliminating the need for a paint booth, compressed air, safety equipment, preparation work, along with operational hazards, volatile organic compound (VOC) emissions, hazardous waste and cleanup work, the virtual reality paint simulator is changing the dynamics of applicator training and bringing high-quality, consistent coatings within the reach of every finishing operation.

IWRC is a service, research, and training organization at the University of Northern Iowa. For more information about the IWRC, visit www.iwrc.org. More information about the VirtualPaint system can be found at www.virtualpaint.us.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!