Streamlining Autodeposition

Autodeposition is faster and more environmentally responsible than conventional coating processes; however, a typical seven-stage autodeposition process still requires several cleaning stages. Recent advances are pushing autodeposition technology past this boundary to offer manufacturers and coaters a coating solution that lowers the environmental impact even further, while also reducing the overall manufacturing production footprint and increasing efficiency in the assembly process.

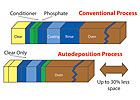

Autodeposition is a waterborne, anticorrosive paint layer applied to metal by means of a chemical reaction rather than by electrical or contact methods. The autodeposition process is simple in comparison to other processes used for applying corrosion-resistant coatings (see Figure 1). Following conventional cleaning and rinsing stages, metal parts are immersed in a coating chemical bath, where the pigment and resin particles are deposited. The growth in film thickness is time-dependent. A rapid deposition rate is followed by a decrease in growth (limited by the diffusion of ions on the metal), which results in a uniform and “self-limiting” coating thickness. A protective barrier film is formed wherever the coating bath makes contact with the metal workpiece. This process is faster and more environmentally responsible than conventional coating processes; however, a typical seven-stage autodeposition process still requires several cleaning stages.

Autodeposition is a waterborne, anticorrosive paint layer applied to metal by means of a chemical reaction rather than by electrical or contact methods. The autodeposition process is simple in comparison to other processes used for applying corrosion-resistant coatings (see Figure 1). Following conventional cleaning and rinsing stages, metal parts are immersed in a coating chemical bath, where the pigment and resin particles are deposited. The growth in film thickness is time-dependent. A rapid deposition rate is followed by a decrease in growth (limited by the diffusion of ions on the metal), which results in a uniform and “self-limiting” coating thickness. A protective barrier film is formed wherever the coating bath makes contact with the metal workpiece. This process is faster and more environmentally responsible than conventional coating processes; however, a typical seven-stage autodeposition process still requires several cleaning stages.

Recent advances are pushing autodeposition technology past this boundary to offer manufacturers and coaters a coating solution that lowers the environmental impact even further, while also reducing the overall manufacturing production footprint and increasing efficiency in the assembly process.

Compared to the seven stages required in a conventional coating process, the advanced autodeposition process has only four process stages where chemicals are used. The phosphate pretreatment stages are eliminated. Instead, the advanced autodeposition process adds cleaning and rinsing stages within the four processes. The use of a reaction rinse after the autodeposition stage allows new properties (such as higher corrosion and chemical resistance performance) to be introduced to the coating before curing.

The coating bath uses a dispersion of a paint emulsion at low solids, along with acidified ferric fluoride. This technique frees ferrous ions that destabilize the emulsion locally at the metal surface, causing the paint layer to be deposited. The process provides a hard yet flexible coating that cannot be achieved with conventional paints.

The advanced autodeposition process is a simple, reliable, industrial-capable finishing system that is employee-friendly. The coating materials are water-based and have extremely low levels of solvents, which means that no flammable or explosive products are present in the process. Thus, there are fewer limitations on the process location, and workers can remain nearby to monitor the process or take part in other manufacturing functions. The autodeposition process also eliminates high-voltage electrical fields in or around the coating tank because there is no need for electricity to deposit the coating in the process.

Since the autodeposition process deposits a coating only on metallic surfaces, the coating of metal in a metal-plastic or metal-rubber assembly is possible. This capability allows manufacturers to reduce capital expenditures and paint shop complexities. Autodeposition coatings are used on automotive seat tracks, drawer slides and some applications normally served by electroplating because of the high hardness and wear resistance of the coating.

The advanced autodeposition coating is also an organic coating technique that decreases energy consumption because no electricity is needed to drive the deposition of the coating. Beyond saving time and energy, other environmentally sustainable initiatives are used in the chemistry of the coating process. Because the water-based coatings have low or zero volatile organic compounds (VOCs), they meet and, in some cases, exceed current clean air legislation. The coatings also contain no heavy-metal anticorrosive pigment, and they do not require toxic heavy-metal based treatments.

Topcoat-primer autodeposition coating systems have been designed and launched with only one curing oven needed in what is commonly known as a “co-cure” process (see Figure 2). This concept reduces process steps and equipment length to give coaters and manufacturers the option to source higher-performance, more affordable topcoat-primer painting operations in areas that previously would allow only lower-performance powder coating systems.

Another advance is a new gray color epoxy-acrylic urethane autodeposition coating that provides all the performance advantages of previous autodeposited coatings with a lighter color basecoat for topcoating with powder and liquid paints. Applications include any ferrous metal part or structure requiring superior cyclic corrosion protection, thermal stability and good topcoat characteristics. The ability of the coating to provide a lighter color primer base and precise film thickness provides the opportunity for lower paint consumption and better topcoat control.

Yet another new development is a coating designed to enhance corrosion performance for demanding applications such as vehicle frames and chassis components. This new coating has achieved 1,000 hours of performance during neutral salt spray testing and has performed similar to cathodic e-coat and zinc phosphate pretreatment on automotive manufacturer cyclic corrosion tests. The epoxy-acrylic urethane coating has excellent thermal stability, topcoat-ability and flexibility. Its small environmental footprint is further reduced with even lower VOCs and the elimination of hazardous air pollutants.

These and other advances are allowing autodeposition coating processes to reduce environmental impact, improve the functional performance of the part and lower total manufacturing costs in automotive paint shops and other applications. The technology already is being used in automotive manufacturing facilities to displace conventional metal pretreatment and electrocoat processes for coating entire vehicle frames. Global research in the automotive industry and at universities is expanding the opportunities for autodeposition coatings even further. Improvements under investigation include reducing cure time/temperature through polymer research, enabling multimetal substrate coating applications, and enhancing surface appearance on all substrates.

For more information, visit www.henkel.com.

*Aquence™, supplied by Henkel Adhesive Technologies.

The advanced autodeposition coating allows manufacturers to eliminate several layers of manufacturing cost and complexity through fewer process steps and controls compared to the conventional coating process. Photo courtesy of Parts Finishing Group.

Figure 1. A conventional coating process compared to autodeposition.

Recent advances are pushing autodeposition technology past this boundary to offer manufacturers and coaters a coating solution that lowers the environmental impact even further, while also reducing the overall manufacturing production footprint and increasing efficiency in the assembly process.

A Safer, More Efficient Process

The newest development in autodeposition coatings* allows manufacturers to eliminate several layers of cost and complexity. It also has the ability to coat large volumes of densely racked or complex shaped metal parts uniformly, giving finishing professionals the choice to coat their parts as an assembly or as individual pieces.Compared to the seven stages required in a conventional coating process, the advanced autodeposition process has only four process stages where chemicals are used. The phosphate pretreatment stages are eliminated. Instead, the advanced autodeposition process adds cleaning and rinsing stages within the four processes. The use of a reaction rinse after the autodeposition stage allows new properties (such as higher corrosion and chemical resistance performance) to be introduced to the coating before curing.

The coating bath uses a dispersion of a paint emulsion at low solids, along with acidified ferric fluoride. This technique frees ferrous ions that destabilize the emulsion locally at the metal surface, causing the paint layer to be deposited. The process provides a hard yet flexible coating that cannot be achieved with conventional paints.

The advanced autodeposition process is a simple, reliable, industrial-capable finishing system that is employee-friendly. The coating materials are water-based and have extremely low levels of solvents, which means that no flammable or explosive products are present in the process. Thus, there are fewer limitations on the process location, and workers can remain nearby to monitor the process or take part in other manufacturing functions. The autodeposition process also eliminates high-voltage electrical fields in or around the coating tank because there is no need for electricity to deposit the coating in the process.

The advanced autodeposition process coats only metallic surfaces in a metal-plastic or metal-rubber assembly. This selectivity allows manufacturers to reduce capital expenditures and paint shop complexities.

Higher Performance with Less Environmental Impact

The advanced autodeposition coating conforms to the shape of the metal surface, yet it is not affected by variances in electrical energy at high and low areas of complex parts. This feature of the process means that the coatings can provide better edge protection than other paint processes while also improving inside-out corrosion performance. Additionally, the coating thickness is uniform throughout the outside and inside of the component. This uniformity allows design engineers to reconsider the need for extra metal structure thickness in areas where conventional coatings will not penetrate.Since the autodeposition process deposits a coating only on metallic surfaces, the coating of metal in a metal-plastic or metal-rubber assembly is possible. This capability allows manufacturers to reduce capital expenditures and paint shop complexities. Autodeposition coatings are used on automotive seat tracks, drawer slides and some applications normally served by electroplating because of the high hardness and wear resistance of the coating.

The advanced autodeposition coating is also an organic coating technique that decreases energy consumption because no electricity is needed to drive the deposition of the coating. Beyond saving time and energy, other environmentally sustainable initiatives are used in the chemistry of the coating process. Because the water-based coatings have low or zero volatile organic compounds (VOCs), they meet and, in some cases, exceed current clean air legislation. The coatings also contain no heavy-metal anticorrosive pigment, and they do not require toxic heavy-metal based treatments.

Figure 2. Comparison of a conventional two-coat process and the autodeposition “co-cure” process.

Continued Advances

Many industrial and automotive component manufacturers are investing in lean or modular manufacturing systems. The key to all of these systems is the need to make and paint more part variations (large, small, with thick or thin metal masses) to reduce in-process inventories and respond more quickly to changes in market demands for different models or components. Advanced autodeposition coatings allow for the opportunity to coat many or a few parts in a single coating bath without requiring adjustments to process conditions or equipment. The coatings also offer the opportunity to design combined primer-topcoat systems that reduce the effective paint line footprint by up to 50% compared to conventional coating systems.Topcoat-primer autodeposition coating systems have been designed and launched with only one curing oven needed in what is commonly known as a “co-cure” process (see Figure 2). This concept reduces process steps and equipment length to give coaters and manufacturers the option to source higher-performance, more affordable topcoat-primer painting operations in areas that previously would allow only lower-performance powder coating systems.

Another advance is a new gray color epoxy-acrylic urethane autodeposition coating that provides all the performance advantages of previous autodeposited coatings with a lighter color basecoat for topcoating with powder and liquid paints. Applications include any ferrous metal part or structure requiring superior cyclic corrosion protection, thermal stability and good topcoat characteristics. The ability of the coating to provide a lighter color primer base and precise film thickness provides the opportunity for lower paint consumption and better topcoat control.

Yet another new development is a coating designed to enhance corrosion performance for demanding applications such as vehicle frames and chassis components. This new coating has achieved 1,000 hours of performance during neutral salt spray testing and has performed similar to cathodic e-coat and zinc phosphate pretreatment on automotive manufacturer cyclic corrosion tests. The epoxy-acrylic urethane coating has excellent thermal stability, topcoat-ability and flexibility. Its small environmental footprint is further reduced with even lower VOCs and the elimination of hazardous air pollutants.

These and other advances are allowing autodeposition coating processes to reduce environmental impact, improve the functional performance of the part and lower total manufacturing costs in automotive paint shops and other applications. The technology already is being used in automotive manufacturing facilities to displace conventional metal pretreatment and electrocoat processes for coating entire vehicle frames. Global research in the automotive industry and at universities is expanding the opportunities for autodeposition coatings even further. Improvements under investigation include reducing cure time/temperature through polymer research, enabling multimetal substrate coating applications, and enhancing surface appearance on all substrates.

For more information, visit www.henkel.com.

*Aquence™, supplied by Henkel Adhesive Technologies.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!